MatterHackers Vice President of Strategic Partnerships, Mara Hitner, is joined by particular visitors Eric Woodridge of Somerset Group School and Mark Holthaus of L3Harris in addition to moderator Robert Schoenberger for an in-depth dialogue on superior supplies and their rising presence in 3D printing, particularly BASF Ultrafuse 316L, a polymer and 316L chrome steel composite filament that yields pure steel parts by way of normal FFF printer techniques and case research using this additive manufacturing course of for instruments, jigs, and fixtures in each the tutorial {and professional} worlds.

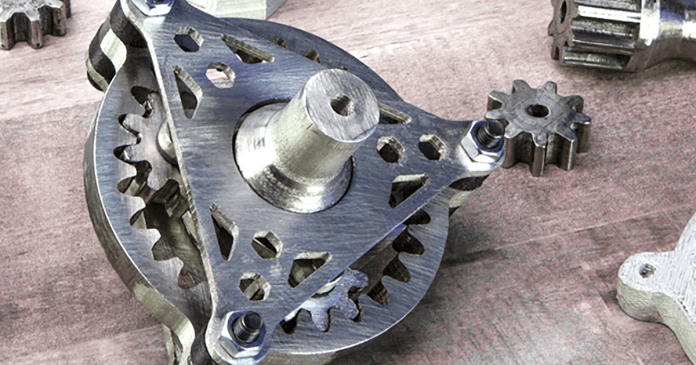

Find out how Somerset Group School is making actual chrome steel steel components on $400 3D printers, sending them away for debinding and sintering, after which machining and welding the components at a fraction of the price of conventional strategies of fabrication. L3Harris is saving hundreds printing 316L in-house versus utilizing service bureaus for his or her work.

The dialogue additionally consists of technical data, such because the parameters and capabilities of working with this materials, together with: hotend and mattress temperatures, nozzle necessities, anisotropic shrinkage, bowden and construct floor compatibility, and extra.

Lastly, the presenters draw parallels between current various conventional manufacturing processes resembling funding casting, the occupational and security hazards related to these strategies, and the position this new expertise may play in changing typical manufacturing processes within the circumstances of fast prototyping or small-scale industrial steel manufacturing.

You should purchase BASF Ultrafuse 316L HERE, or e mail gross sales@matterhackers.com with questions on how to make sure success together with your use case.