Researchers on the U.S. Nationwide Institute of Requirements and Expertise (NIST) have found a beforehand unknown crystal construction whereas learning a 3D printed aluminum alloy, a discovering that would result in stronger and extra dependable additively manufactured parts.

The brand new section, a quasicrystal with fivefold symmetry, was recognized in an aluminum-silicon-zirconium alloy produced utilizing laser powder mattress fusion (LPBF). Quasicrystals are recognized to exhibit uncommon properties akin to excessive energy and low thermal conductivity, making them helpful for engineering purposes.

What are quasicrystals?

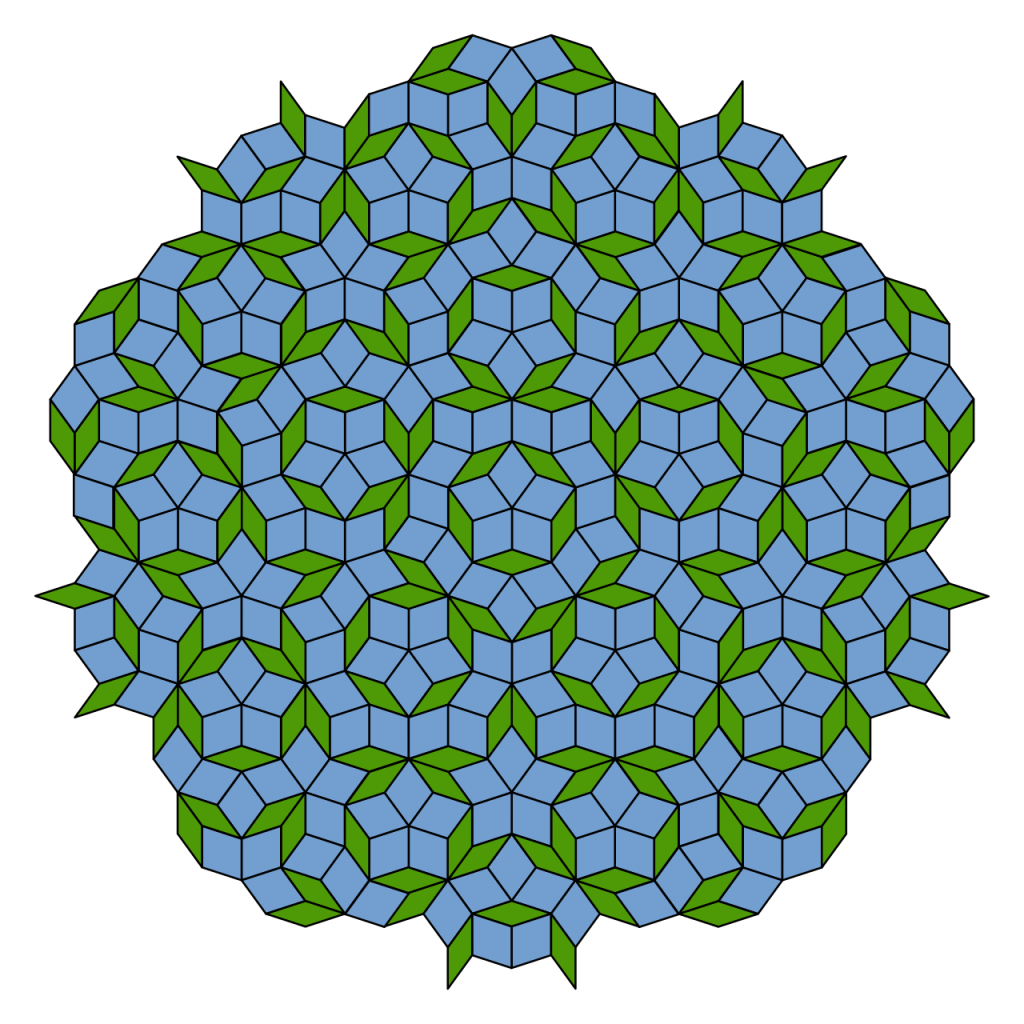

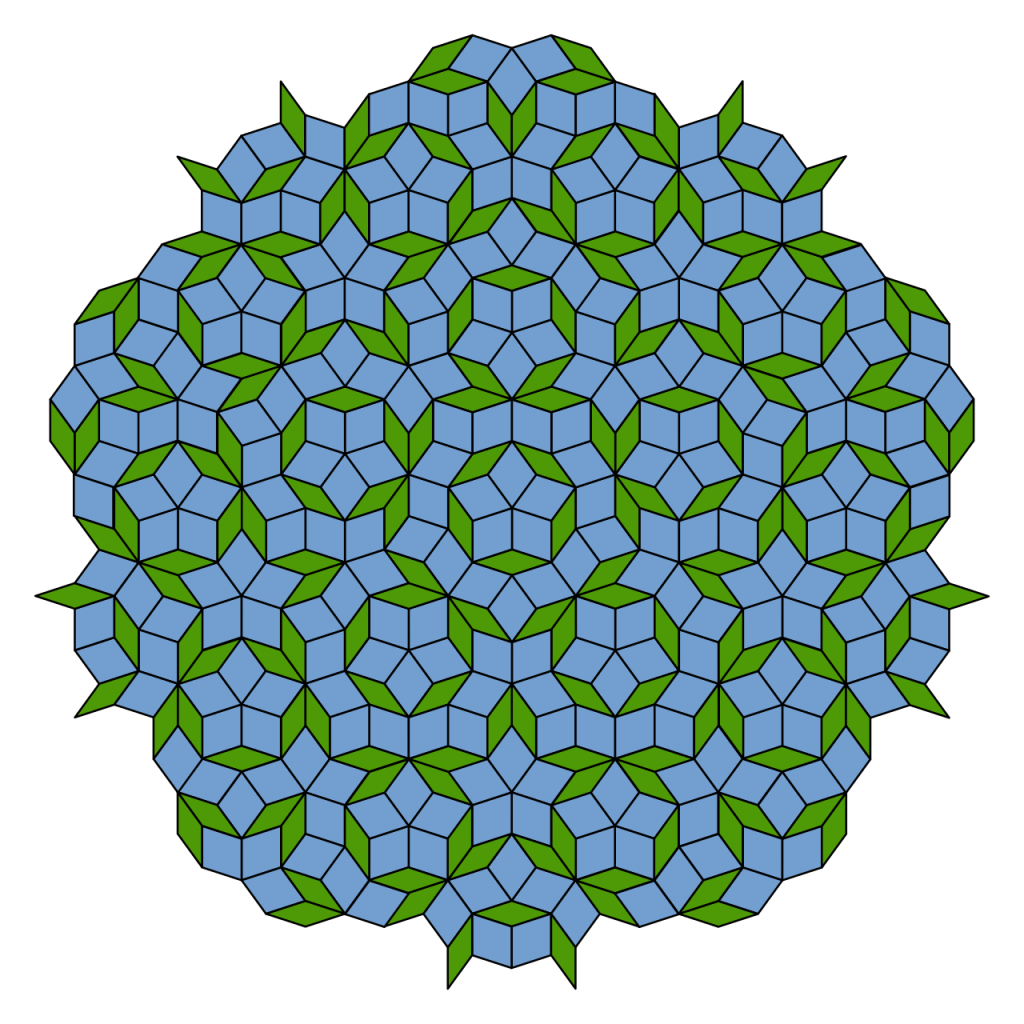

Quasicrystals are solids with an ordered atomic construction that doesn’t repeat periodically. In contrast to typical crystals, which type repeating patterns in area, quasicrystals observe mathematical guidelines with out repeating, very like a Penrose tiling. Out of the 230 potential crystal area teams, quasicrystals match into none.

These constructions are extraordinarily uncommon in nature, present in locations like meteorites. In 1982, Israeli scientist Dan Shechtman found artificially shaped quasicrystals in a lab-made alloy, an achievement that gained him the Nobel Prize in Chemistry in 2011.

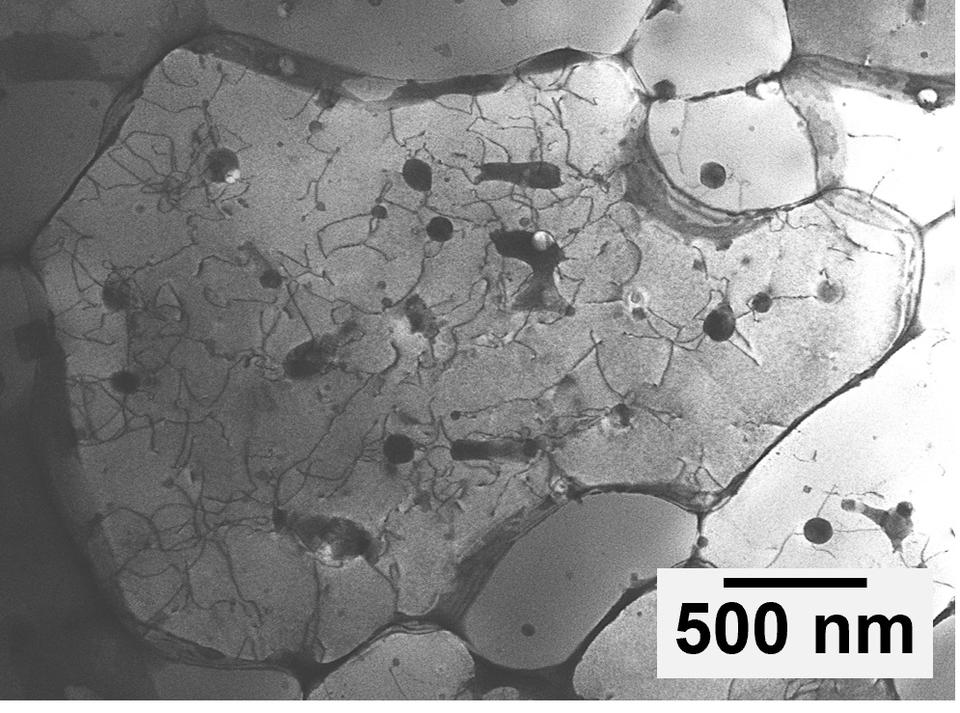

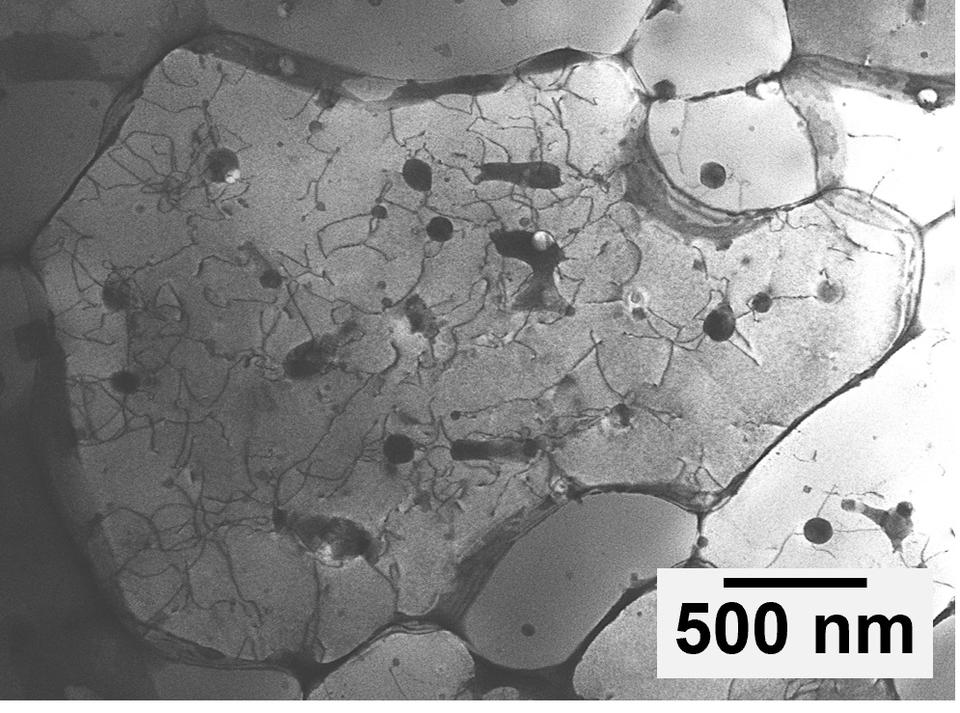

A long time later, NIST researcher Andrew Iams recognized a brand new quasicrystalline section throughout a 3D printing course of involving an aluminum alloy. The invention was not intentional, it emerged from routine microscopic evaluation of samples created by way of LPBF.

The invention

Iams noticed that the crystal exhibited fivefold rotational symmetry, that means the atomic association appears to be like the identical when rotated 72 levels round an axis. This kind of symmetry is taken into account “forbidden” in conventional crystallography, the place solely symmetries like twofold, threefold, fourfold, or sixfold are permitted.

By fastidiously rotating the pattern below a transmission electron microscope, Iams discovered that the construction additionally displayed threefold and twofold symmetries when considered from totally different instructions. These a number of axes of symmetry, mixed with the non-repeating atomic order, confirmed that the construction was a quasicrystal.

Challenges in steel 3D Printing

Though steel 3D printing permits for designs and materials behaviors not potential with conventional manufacturing, it faces vital limitations, significantly with aluminum alloys.

In accordance with NIST physicist Fan Zhang, “Excessive-strength aluminum alloys are nearly unattainable to print, as they have an inclination to develop cracks, which make them unusable.”

One of many key points is temperature management. Aluminum melts at round 660°C, whereas the lasers utilized in LPBF can exceed 2,400°C. These excessive situations may cause undesirable microstructures or thermal stresses, resulting in half failure.

In 2017, researchers at HRL Laboratories and UC Santa Barbara discovered that including zirconium to aluminum powders helped stabilize the solidification course of and scale back cracking, leading to a printable aluminum alloy. The NIST alloy used on this latest research builds on that innovation, demonstrating how alloy design continues to evolve with additive manufacturing.

Advancing aluminum alloys for additive manufacturing

The invention of a quasicrystal in a 3D printed aluminum alloy aligns with ongoing efforts to develop aluminum alloys optimized for additive manufacturing. Conventional high-strength aluminum alloys, akin to Al7075 and Al6061, are susceptible to cracking throughout LPBF processes. To deal with this, researchers at HRL Laboratories launched zirconium-based nanoparticles into aluminum alloys, enabling the manufacturing of crack-free, high-strength aluminum parts by way of LPBF.

Constructing on this, Constellium and Morf3D developed AHEADD CP1, an aluminum-iron-zirconium alloy tailor-made for LPBF. This alloy affords excessive energy and ductility, environment friendly processing, and simplified post-processing, making it appropriate for purposes like warmth exchangers.

These developments underscore the significance of alloy improvement in overcoming the challenges of steel additive manufacturing, paving the way in which for extra dependable and high-performance 3D printed parts.

What 3D printing traits must you be careful for in 2025?

How is the way forward for 3D printing shaping up?

Subscribe to the 3D Printing Trade publication to maintain up with the newest 3D printing information.

You too can observe us on LinkedIn and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits an electron microscope picture of the aluminum alloy from the research. Picture by way of NIST.