Tech Mushy 3D, a U.S. developer of engineering software program toolkits for visualization and knowledge trade, has launched HOOPS AI, a framework designed to make computer-aided design (CAD) knowledge accessible for machine-learning workflows. The system integrates CAD entry, dataset preparation, and encoding in a single setting, enabling knowledge scientists to maneuver instantly from uncooked geometry to reproducible fashions with out counting on exterior conversion instruments.

Machine studying has reshaped manufacturing and product improvement, but CAD info—central to engineering design—stays tough to make use of in algorithmic coaching. Changing 3D geometries into machine-readable codecs often requires fragmented scripts, handbook corrections, and dependence on costly proprietary methods.The software program eliminates these boundaries by combining entry, preparation, and encoding in a single reproducible pipeline. Constructed on HOOPS Alternate, Tech Mushy 3D’s established CAD import and export library, the framework gives direct, high-fidelity entry to over thirty file codecs overlaying geometry, topology, assemblies, product manufacturing info (PMI), and metadata by means of a Python API. This structure avoids dangerous intermediate conversions and reduces reliance on native CAD purposes.

Based on Gavin Bridgemann, Chief Know-how Officer on the agency, “HOOPS AI represents a significant leap ahead for organizations trying to lastly harness synthetic intelligence for 3D CAD. It supplies a whole, reproducible pipeline that makes machine-learning workflows with CAD knowledge each sensible and scalable.” The toolkit manages ingestion, versioning, and experiment monitoring for traceable outcomes whereas together with utilities for visualization, segmentation, cleansing, and encoding so groups can generate constant datasets for mannequin improvement.

Tech Mushy 3D says the system automates large-scale dataset preparation and end-to-end workflow orchestration throughout the complete machine-learning lifecycle. Storage and logging parts file each experiment to make sure repeatability and traceability—capabilities required for verifiable analysis and mannequin validation. Visualization instruments embedded within the setting enable inspection of intermediate phases, giving customers perception into dataset integrity earlier than mannequin coaching begins. By integrating these phases into one managed pipeline, HOOPS AI eliminates the delicate, script-based workflows that usually gradual data-driven engineering.

The corporate’s established position within the CAD-software ecosystem underpins its capability to assist this new platform. Its know-how is embedded in instruments from Ansys, Siemens, Hexagon, NVIDIA Omniverse, Unreal Engine, and Unity 3D, offering the info translation spine for a lot of industrial and visualization purposes. Expertise processing massive volumes of CAD knowledge for these distributors kinds the idea for HOOPS AI’s concentrate on reliability and scale. With greater than 750 impartial software program distributors already utilizing its software program improvement kits, Tech Mushy 3D plans to increase HOOPS AI entry to this community and to analysis teams creating AI strategies for design, simulation, and manufacturing.

Makes an attempt to use machine studying to CAD knowledge have been constrained by inconsistent codecs and restricted interoperability between platforms. Tutorial analysis has explored utilizing neural networks for generative design and have detection, however translating industrial CAD fashions into usable datasets stays expensive and time-consuming. In business software program, progress has centered on proprietary options; Siemens has built-in AI-assisted design inside its Xcelerator platform, whereas Autodesk’s analysis division has examined automation of repetitive modeling duties. These examples illustrate the absence of a common, vendor-neutral framework able to connecting CAD geometry with machine studying—a problem HOOPS AI instantly addresses.

Based in 1996 and headquartered in Bend, Oregon, Tech Mushy 3D operates places of work in France, England, Japan, Germany, and Norway. Backed by funding agency Battery Ventures, the corporate supplies software program improvement kits used for CAD and CAE knowledge conversion, visualization, and simulation throughout engineering and manufacturing sectors.

Tech Mushy 3D has opened a know-how preview to permit builders and companions to guage efficiency inside present workflows. customers can request entry by means of the corporate’s web site at techsoft3d.com/builders/merchandise/hoops-ai.

Assist form the 2025 3D Printing Trade Awards. Join the 3DPI Skilled Committee in the present day.

Prepared to find who received the 2024 3D Printing Trade Awards?

Subscribe to the 3D Printing Trade publication to remain up to date with the most recent information and insights.

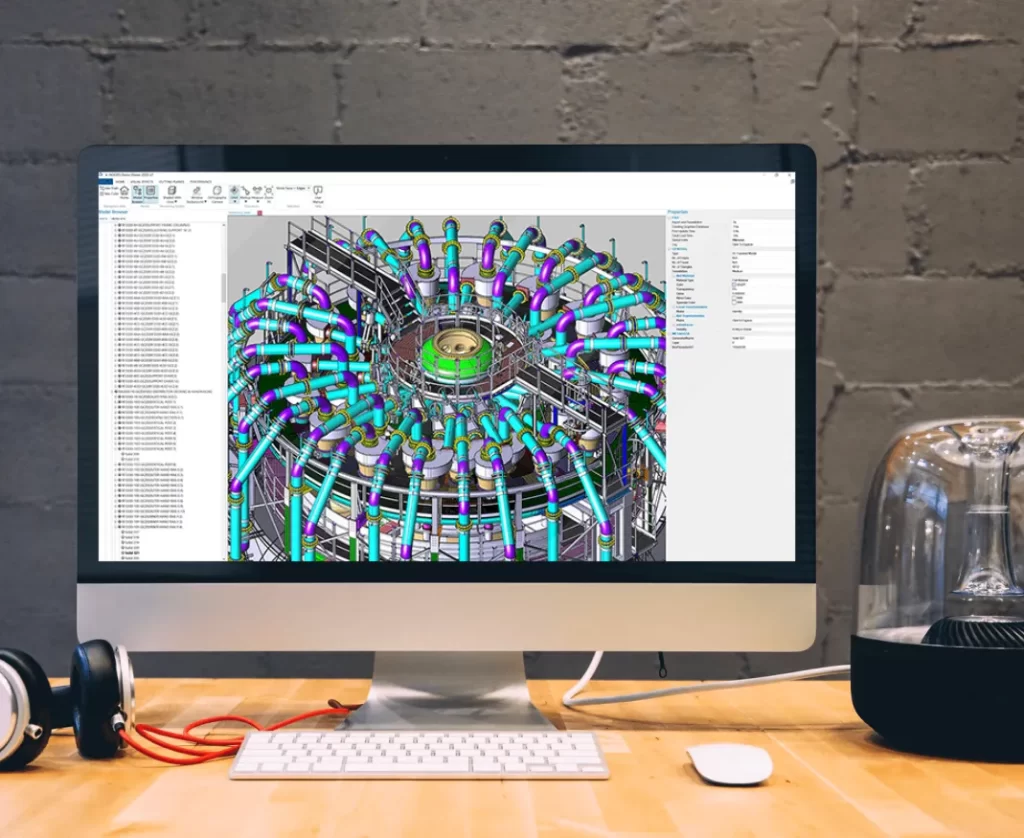

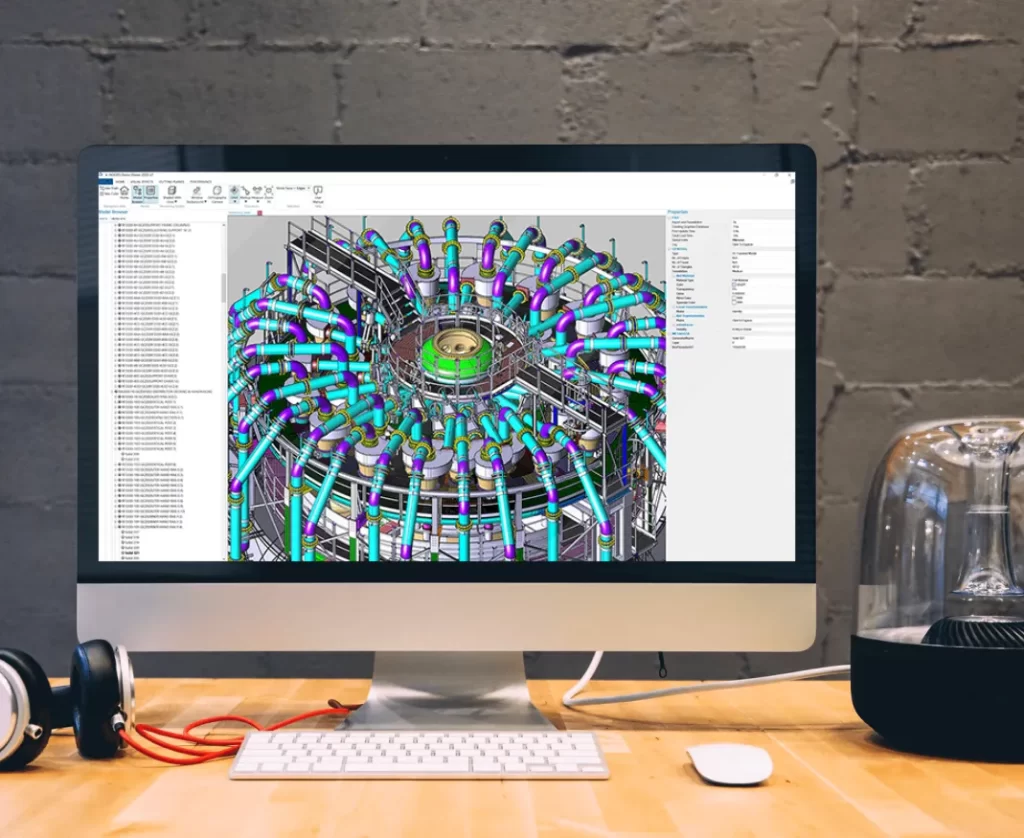

Featured picture reveals 3D geometry processed by HOOPS AI framework. Picture through Tech Mushy 3D.