The Execs at MatterHackers take an in-depth take a look at the capabilities and options on the absolutely customizable Pulse 3D Printer & the NylonX-ready Pulse XE 3D Printer.

Posted on February 21, 2018

by

Taylor Landry

Pulse 3D Printer

The Pulse presents a totally customizable, absolutely assembled printer, with top-of-the-line options, at an reasonably priced worth. Made by MatterHackers professionals proper right here in Orange County, California, you may be assured you’ll be receiving an superior printer backed up by service and assist for the lifetime of your Pulse 3D printer.

The Absolutely Customizable Pulse 3D Printer

Options:

- Absolutely Computerized Mattress Leveling

- Motor dampers for practically silent operation

- Identify-brand elements from E3D, BondTech, Panucatt, Olsson Ruby, and Ultimachine

- Filament run-out detection

- Computerized firmware updating

- Presets for just about each filament at the moment out there

- Customizable – the whole lot you need, nothing you don’t

Computerized Leveling

The Pulse makes use of an Orbit probe, by BLTouch, and MatterControl to supply absolutely automated mattress leveling. Press a button, and Pulse does the remaining. MatterControl shops the probing information so that you don’t must calibrate earlier than each print – saving you time, and providing you with repeatable outcomes. As a result of it’s a contact probe, and never inductive like many mattress probes, you may swap out mattress surfaces with out worrying about interfering with the probe.

The Orbit Mattress Leveling Contact Sensor in Motion

Print Restoration and Filament Run-Out Detection

Have you ever ever misplaced a print as a result of your pc determined to fall asleep or drive a Home windows replace? How about whenever you assume you’ve sufficient filament left on the spool and are available again to seek out out you have been a couple of grams quick?

Pulse has received you coated. MatterControl has print restoration which detects failed prints attributable to an influence outage, disconnection, or different breaks within the communication with the printer, and can robotically resume and get better your print. The built-in filament run-out detector senses whenever you’re out of filament, pauses the print, lifts the hotend out of the best way, and notifies you through textual content or e-mail that you just’re out of filament. Change the filament, and your print will resume. No extra failed prints and wasted filament.

The Filament Runout Sensor

Extremely-Quiet Printing

Each Pulse comes customary with motor dampers on the X, Y, and Z axes. These drastically scale back vibrations, providing you with cleaner, smoother prints, they usually considerably scale back noise. The Pulse additionally comes with silicone toes. These dampen the vibrations between the printer and the floor you might be printing on and scale back the noise of the machine when printing. The Pulse is well one of many quietest printers we’ve ever used.

Motor dampers make the Pulse a quiet desk companion.

Print Each Filament

One of many coolest issues in regards to the Pulse is that it may be configured to print actually each filament that we stock. The bottom mannequin comes with an E3D Lite6 hotend and SeeMeCNC EZRstruder, which might deal with most filaments, together with some flexibles, and may print as much as 245°C.

Improve to the BondtechQR extruder and E3Dv6 with hardened metal nozzle, and you’ll print each filament in our library – from flexibles like Ninjaflex and TPU, to abrasive composites like NylonX and carbon fiber PLA.

Garolite mattress and Olsson Ruby Nozzle upgrades provide the final efficiency when printing NylonX and different nylon filaments

Examined, Tuned, and Up to date

Once you order a Pulse, we customise the firmware to the specs of your machine, and we additionally ensure that MatterControl is ready up and able to use. We do all of the setup on the again finish so you will get proper to printing; no extra {hardware} updates, or twiddling with part profiles – it’s already taken care of.

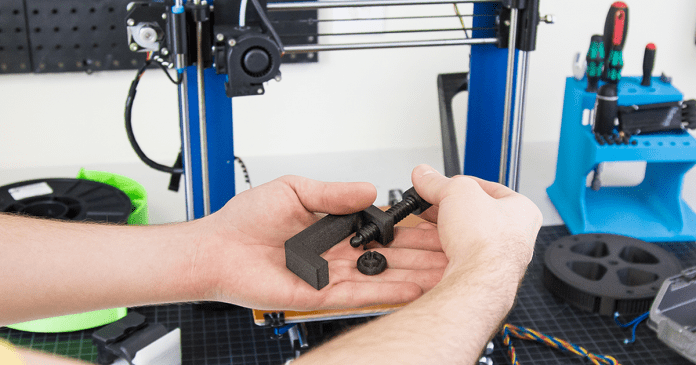

We print all the printed components for the Pulse on different Pulse 3D printers. We’ve got hundreds of print hours on the machines, and maintain the profiles up to date with what we’ve discovered to supply the very best, most constant outcomes with our filament line. MatterControl robotically checks for firmware updates and may apply any updates with a single mouse-click. Want a cloth profile tweaked or adjusted for particular outcomes? Tell us and we are able to ship you a personalised profile to import.

Pulse XE – The NylonX 3D Printer

The Pulse XE 3D Printer

The Pulse XE is the fully-upgraded model of the Pulse. It consists of the next tools customary:

This construct can be absolutely assembled and examined by the MatterHackers Execs earlier than being shipped out, and all software program attributes are loaded into your MatterControl account for simple setup and fast printing out of the field. It’s particularly designed to print NylonX, our very personal model of nylon filament infused with carbon-fiber strands – an amazingly inflexible and sturdy materials that may stand as much as each day use. In fact, you too can print another filament – you aren’t restricted to solely nylon. As a result of it consists of the Olsson Ruby Nozzle and a Bondtech Extruder, you may print fantastically in ABS, PLA, PETG and all different filaments with ease.