Steel–natural frameworks are transitioning from laboratory curiosity to industrially viable supplies pushed by in depth neighborhood efforts to reinforce their performance and stability, and by breakthroughs in large-scale manufacturing.

This 12 months’s Nobel Prize in Chemistry went to Susumu Kitagawa, Richard Robson and Omar Yaghi for the event of metallic–natural frameworks (MOFs) and demonstration of their potential. This can be a huge increase for the MOFs neighborhood. We need to take this event to congratulate the awardees and replicate on the journey that MOFs have skilled from their conception to industrial adoption, with some common remarks about nanoscience alongside the best way.

Credit score: Thom Leach / Science Picture Library / Getty Inventory Pictures

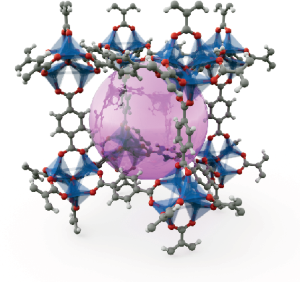

MOFs are crystalline supplies composed of metallic ions or clusters linked by natural linkers, forming extremely ordered, prolonged nanoporous networks. These constructions have extraordinarily excessive floor areas — some frameworks exhibit floor areas equal to the world of a soccer (soccer) area contained in a gram-scale pattern. The modular and reticular nature of MOFs permits researchers to fine-tune their chemical and bodily properties by choosing each the metallic nodes and natural linkers. Such artificial flexibility permits exact management over pore dimension, form, and chemical performance, permitting the frameworks to be tailor-made for interactions with particular sorbate molecules or energetic catalytic websites. In consequence, MOFs have emerged as versatile platforms for a variety of functions, together with gasoline storage (for instance, H2, CH4)1, gasoline separation (for instance, CO2/CH4, CO2/N2)1,2, water harvesting from air3 and heterogeneous catalysis4. They’re additionally promising candidates for environmental remediation, equivalent to pollutant seize and detoxing5,6.

It’d sound apparent, however MOFs are quintessential nanomaterials. The pore dimension of MOFs is very variable and might be exactly engineered to vary from the nanometre to the sub-nanometre scale. However not all nanoporous supplies exemplify the essence of nanoscience as MOFs do. Nanoscience, at its core, is a technique that permits researchers to grasp and management matter on the smallest doable scale. It’s this notion of ‘management’ — management within the selection of ligands, management within the selection of the metallic centre — that makes MOFs so pleasing and engaging to work with, and so ‘nano’.

Though MOFs have demonstrated exceptional structural and useful versatility, their approach to sensible deployment has not been simple. Probably the most persistent points has been their restricted stability. Many early MOFs degrade or collapse underneath publicity to water, humidity, acidic or fundamental environments, or elevated temperatures. In consequence, their dealing with has traditionally been confined to rigorously managed laboratory situations. In recent times, nonetheless, important progress has been made towards enhancing MOF stability. Advances in metallic–ligand coordination chemistry, framework topology, and post-synthetic modification have yielded sturdy MOFs able to sustaining structural integrity even underneath harsh environmental situations7,8.

Parallel industrial efforts are additionally advancing the sphere, with growing consideration to mass manufacturing and price discount. In October 2023, BASF scaled up CALF-20 (a Zn-based MOF) to a number of hundred tons per 12 months for Svante Applied sciences, who desires to make use of it for carbon seize functions9. Different corporations, for example, Numat Applied sciences from USA and UK-based specialist producer, Promethean Particles, have additionally efficiently established MOF manufacturing at industrial scales10. To cut back the prices, Atoco, an organization based by Yaghi, has been working to synthesize sure specialised linkers in-house11.

Synthetic intelligence (AI)-assisted and automatic approaches might additional shorten the design–synthesis–testing path, cut back the event prices, and speed up the scalable manufacturing of industrially related MOFs. Current progresses mix deep studying and generative fashions to design new frameworks optimized for particular gases or reactions, as graph neural networks seize the topological and chemical complexity of MOFs with significantly better accuracy12,13. Integration with high-throughput robotic platforms and automatic synthesis techniques — such because the closed-loop autonomous supplies discovery platform and different experimental robotic techniques — now permits AI algorithms to suggest, synthesize, and take a look at supplies in iterative cycles14. Generative foundational fashions educated on giant supplies datasets and enormous language model-assisted design are rising to translate chemical intent immediately into possible MOF constructions15. Collectively, they could assist to speed up the supply of extra MOFs to the market.

Every time there’s a clear connection between exact nanoscale understanding and macroscopic supplies properties, there are the components for a profitable nanoscience-enabled know-how. MOFs are a good looking instance of this.