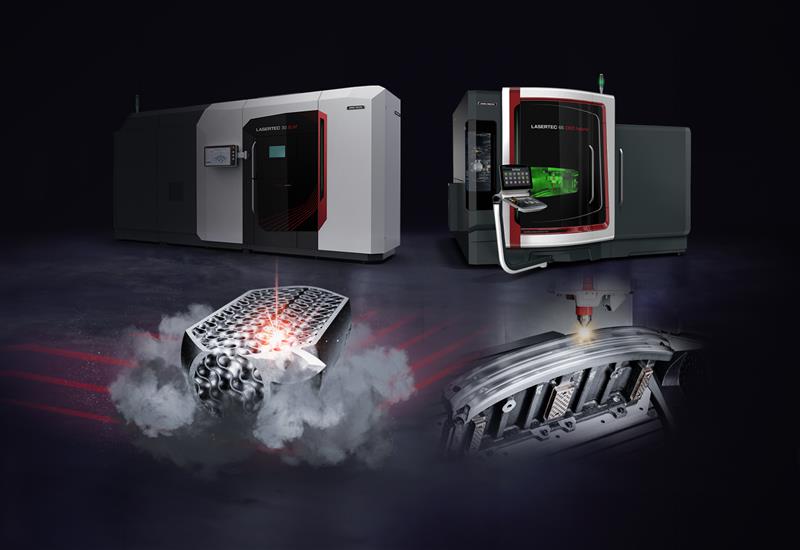

As one of many world’s main CNC machine software producers, DMG MORI is strengthening its place throughout each standard and additive manufacturing (AM). At Formnext 2025 (November 18–21, Frankfurt), the corporate offered new developments that push hybrid and powder mattress applied sciences nearer to true industrial-scale manufacturing.

With its LASERTEC DED hybrid and LASERTEC SLM techniques, DMG MORI has demonstrated how AM can transfer past prototyping and grow to be totally embedded inside environment friendly, automated workflows.

“Hybrid manufacturing is now not a distinct segment—it’s turning into the brand new customary for environment friendly, versatile manufacturing,” mentioned Patrick Diederich, Managing Director DMG MORI Ultrasonic Lasertec GmbH. “By merging additive and subtractive processes into one seamless workflow, we’re redefining what industrial manufacturing can obtain,” mentioned Diederich.

Hybrid Manufacturing: Six Processes, One Machine

On the core of this strategy are the LASERTEC DED hybrid machines, combining six manufacturing steps—milling, turning, grinding, preheating, laser deposition welding, and 3D scanning—inside a single setup. This 6-in-1 configuration permits end-to-end half manufacturing in a single clamping operation, dramatically slicing lead occasions and eliminating the necessity for exterior processes, transport, or rework.

The power to alternate between additive and subtractive modes lets customers create advanced geometries and multi-material elements with enhanced put on resistance, corrosion safety, or chemical stability. Elements corresponding to software inserts may also be repaired relatively than changed, extending service life and decreasing downtime.

New course of improvements, together with preheating, cut back inside stress and stop cracking between base and deposited supplies, enhancing mechanical efficiency. A tool-changer built-in 3D laser scanner ensures exact, non-contact high quality inspection with false-color imaging, whereas blue laser know-how expands capabilities to extremely reflective metals like copper and permits graded materials transitions for superior, high-performance elements.

“These new capabilities remodel a fancy, multi-step course of right into a streamlined, automated workflow—demonstrating that hybrid manufacturing is prepared for collection manufacturing. It reveals how additive manufacturing can complement, not compete with, conventional machining by combining the perfect of each worlds to spice up productiveness and half efficiency,” mentioned Diederich.

Powder Mattress Effectivity: LASERTEC 30 SLM third Era

Within the powder mattress fusion house, DMG MORI’s LASERTEC 30 SLM third Era addresses one among steel AM’s main challenges: downtime between builds. Its new interchangeable construct container system permits accomplished jobs to be swapped out rapidly—no cooling delays—maintaining manufacturing working virtually repeatedly. Setup time is additional diminished by way of exterior build-plate preparation, minimizing inert gasoline consumption and avoiding repeated chamber purging. A sealed lid additionally permits protected powder dealing with.

A strengthened course of chamber with energetic Z-axis compensation ensures layer stability and positional accuracy, and as much as 4 overlapping lasers allow sooner, extra constant outcomes. The expanded 325 × 325 × 400 mm construct quantity permits bigger elements or a number of elements in parallel, making the system supreme for serial manufacturing.

The machine is operated intuitively through CELOS X with easyAM, combining sensible controls with built-in course of monitoring for constant half high quality. Its built-in digital camera system repeatedly displays every layer, detecting and analyzing floor irregularities in actual time.

DMG MORI demonstrated the know-how at Formnext 2025 by printing a robotic head from its Robo2Go Open system, and in addition offered rePLUG FLEX, an optimized powder module developed for economical materials adjustments in small collection or particular purposes.

“At DMG MORI, we see AM not as an remoted know-how, however as an integral a part of a better, extra linked manufacturing ecosystem. By combining course of chains, digital options, and skilled steerage, we empower producers to maneuver from idea to collection manufacturing with confidence. That is how we flip innovation into measurable worth,” mentioned Diederich.

Wish to assist form the way forward for AM? Be part of the Skilled Committee for our 2025 3DPI Awards, launching later this summer time.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Trade e-newsletter or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our YouTube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals LASERTEC SLM techniques. Picture through DMG MORI.