Using 3D printing within the development trade was as soon as thought of a little bit of a gimmick. A decade in the past, barely per week would go by with out an announcement relating to a primary 3D printed home, resort, workplace – even a fortress. In the present day, it has discovered itself an acceptable area of interest in offering compact housing options, which could be quickly constructed the place wanted, and in modular or complicated constructions – akin to bridges and sculptures – that conventional strategies would discover both difficult or unattainable to ship. Simply this week, for instance, we reported on the completion of Japan’s first government-approved two-story 3D printed strengthened concrete home – the profit, makers COBOD Worldwide consider, is the flexibility of 3D printed strengthened concrete to function a ‘structural various to timber development in one of many world’s most earthquake-prone areas.’

In the present day, a brand new analysis challenge on the RWTH Aachen College Chair Digital Additive Manufacturing (DAP) goals to take one other leap, by not solely utilizing 3D printing to construct, however to take waste from the development trade and repurpose it as printing feedstock.

The UN World Development Report 2024/25 claims over a 3rd of world energy-related CO₂ emissions and 32% of worldwide vitality consumption comes from the development sector. This BMWE-funded analysis challenge – known as Additive Manufacturing of 3D Connection Components in Development (AddMamBa) – plans to discover if CO₂ emissions and useful resource consumption from the sector could possibly be considerably decreased through the use of recycled metal to construct reusable 3D printed facade brackets.

The challenge focuses on constructing facade brackets for ventilated facade programs (VHF) and connectors for load-bearing constructions, utilizing laser-based powder mattress fusion and steel powder derived from metal scrap. The scrap is first sorted and analysed in line with its situation and chemical composition after which undergoes a fuel atomisation (VIGA) course of to create the powder, which is then sieved to ship a particle dimension fraction of 15-45 micrometres, prepared for printing.

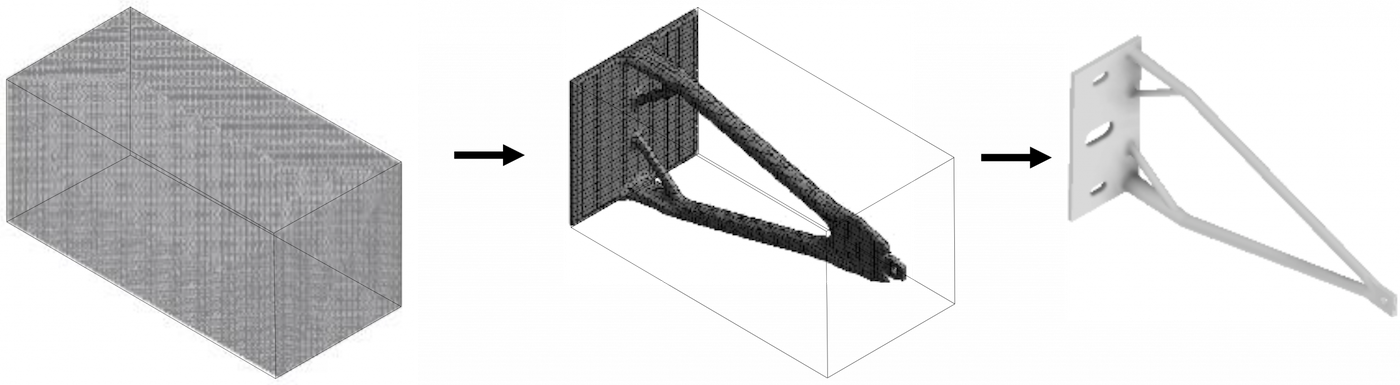

3D printing permits facade connections to be designed with out the necessity for instruments or moulding, and tailored for required constructing geometries. The researchers are additionally using topology optimisation to allow load-path-oriented materials distribution. A digital planning device has additionally been developed to assist with choosing appropriate bracket options based mostly on constructing and facade knowledge, and substructure configuration. It additionally takes under consideration related requirements, particularly DIN EN 1991-1-4/NA.

The challenge is designed to be round, that means elements could be demounted and reused. Preliminary Life Cycle Evaluation (LCA) calculations based mostly on conservative electricity-mix eventualities counsel a World Warming Potential of 23.8 to 33.5 kg CO₂ equivalents per kilogram of element (2030), with an extra downward pattern anticipated because of the rising share of renewable vitality sources. The evaluation additionally reveals that offsetting the upper manufacturing-related emissions via operational financial savings is simplest in buildings with typical fuel heating programs, however much less so when mixed with trendy warmth pump programs. This discovering, in line with the researchers, emphasises the significance of the round economic system side of the challenge. In experimental trials, roughly 60% usable steel powder was recovered from the processed metal scrap (30 kg of powder from 50 kg of scrap).

In a press launch, the researchers stated the challenge ‘establishes a concrete software pathway for making secondary supplies usable inside the AM course of chain’ and ‘unlocks the potential to transform metal scrap into high-quality elements, thereby serving to to shut materials loops within the development sector.’