Researchers from Montanuniversität Leoben in Austria and the Fraunhofer Institute for Ceramic Applied sciences and Methods (Fraunhofer IKTS) in Germany have revealed an in depth research figuring out and classifying strength-limiting defects in additively manufactured ceramics. Titled “Energy limiting defects in additively manufactured ceramics” and revealed by way of Open Ceramics, the paper offers a complete classification system for describing defects throughout main ceramic 3D printing processes, together with vat photopolymerization (VPP), materials jetting (MJT), and materials extrusion (MEX). The analysis was led by Maximilian Staudacher of Montanuniversität Leoben, in collaboration with Tanja Lube, Eric Schwarzer-Fischer, Johannes Abel, and colleagues from Fraunhofer IKTS in Dresden.

Ceramic additive manufacturing (CAM) permits the fabrication of complicated geometries, inner channels, and high-strength elements for aerospace, mechanical, and biomedical purposes. Regardless of these benefits, elements produced by means of VPP, MJT, or MEX ceaselessly exhibit decrease mechanical power and inferior floor high quality in comparison with conventionally processed ceramics. The discrepancy is essentially brought on by microscopic irregularities—equivalent to pores, delamination, and inclusions—that originate throughout fabrication.

On this research, the authors distinguish between “flaws,” small-scale irregularities which are unavoidable in brittle supplies, and “defects,” process-induced imperfections that considerably cut back power. Their classification system hyperlinks defect varieties to every stage of fabrication, from slicing and feedstock preparation to cleansing and dealing with. The group manufactured check specimens utilizing a CeraFab 8500 3D printer from Austrian ceramic 3D printing specialist Lithoz GmbH, alongside modified Prusa i3 MK3S+ print heads from Czech producer Prusa Analysis, and a Multi Materials Jetting (MMJ) system developed by AMAREA Know-how GmbH, a Dresden-based additive manufacturing firm.

All specimens had been produced and sintered at Fraunhofer IKTS, a analysis institute centered on superior ceramics and system integration, whereas fracture testing was carried out at Montanuniversität Leoben utilizing four-point bending setups. The mix of microscopy, scanning electron evaluation, and fractography enabled exact identification of defect morphology and origin.

Key findings throughout additive strategies

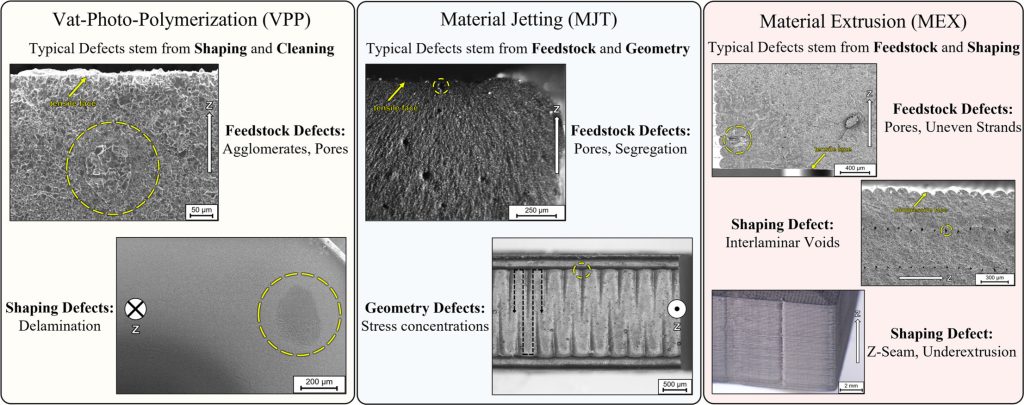

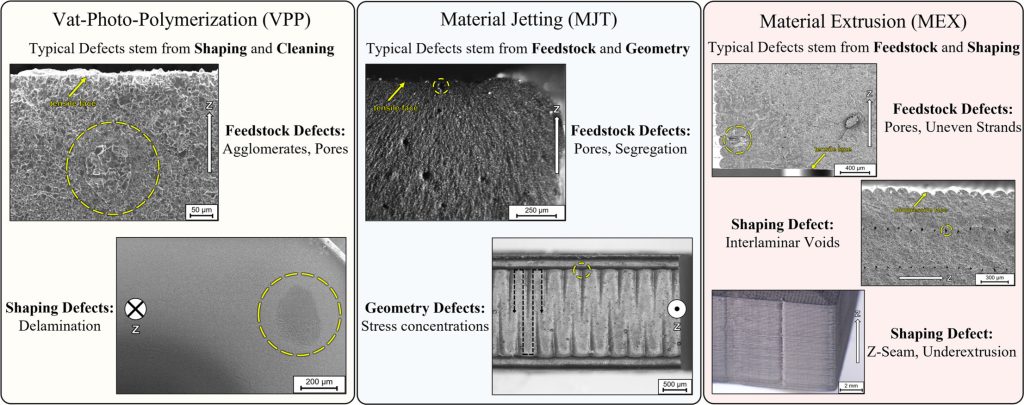

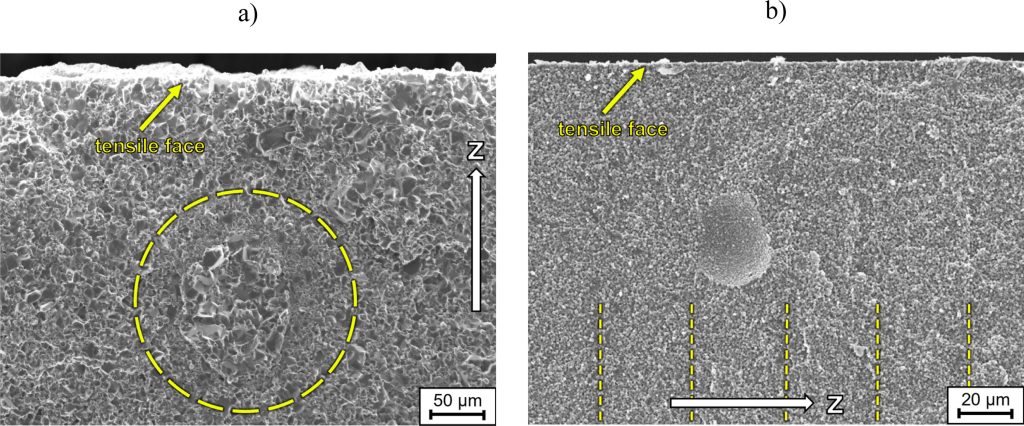

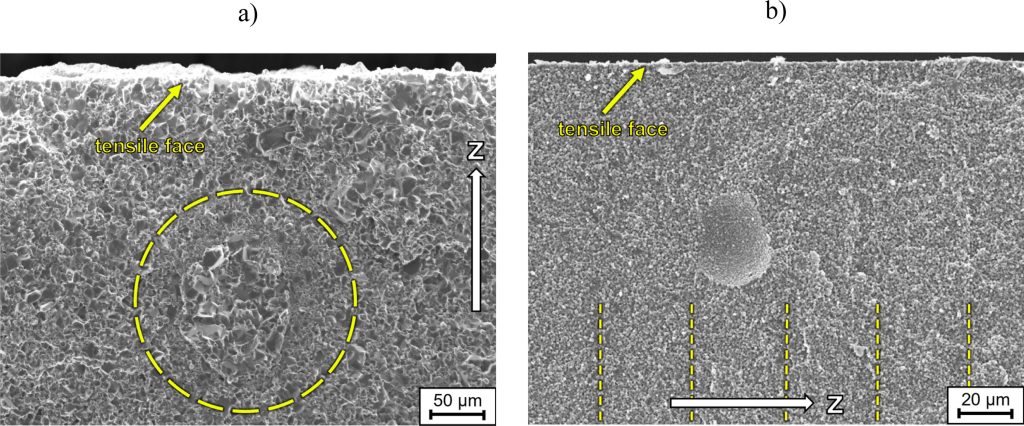

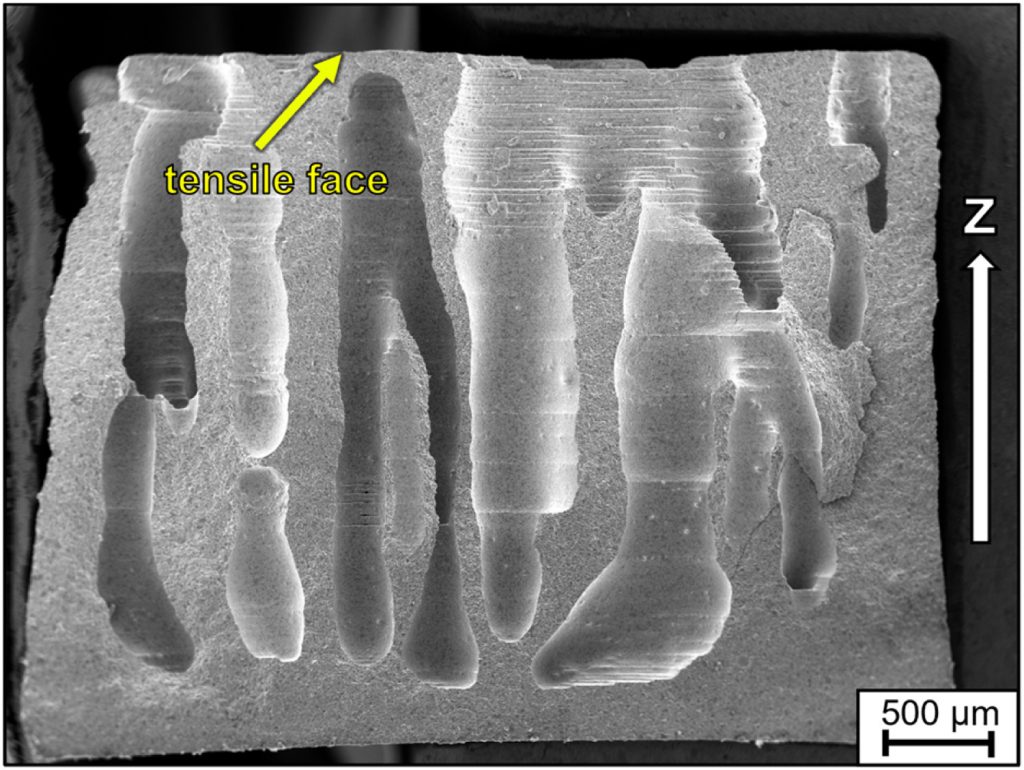

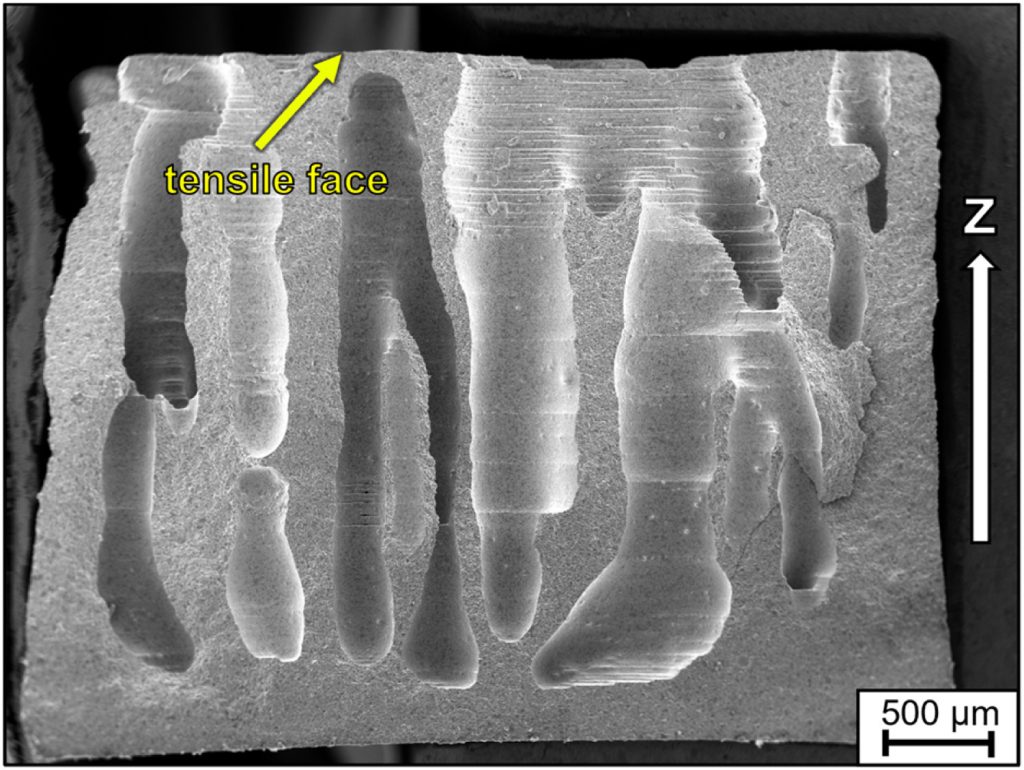

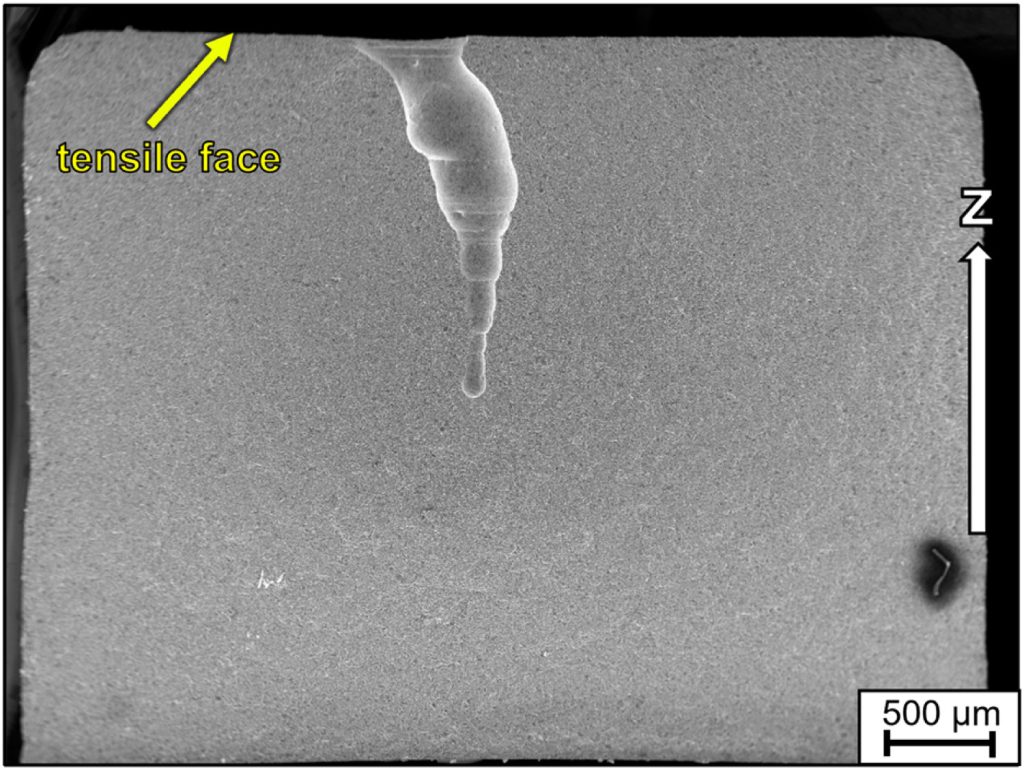

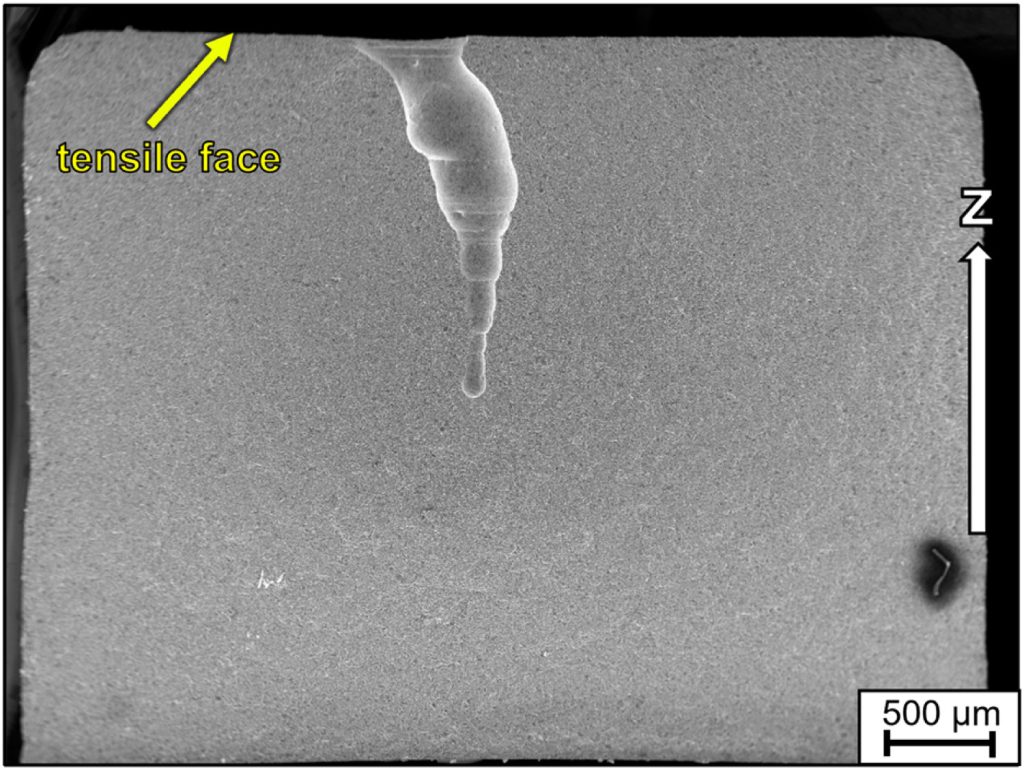

Throughout all examined strategies, pores, agglomerates, weak layer adhesion, and delamination emerged as recurring strength-limiting defects. In vat photopolymerization, improper publicity parameters and inadequate slurry top led to “wormhole” defects—elongated pores propagating throughout a number of layers. Extreme cleansing utilizing ethanol or ultrasonic baths precipitated floor flaking and partial dissolution of inexperienced our bodies. In materials jetting, nozzle clogging and inconsistent droplet formation created voids and floor stress concentrations, whereas edge defects and geometric transitions between perimeter and infill contributed to early failure.

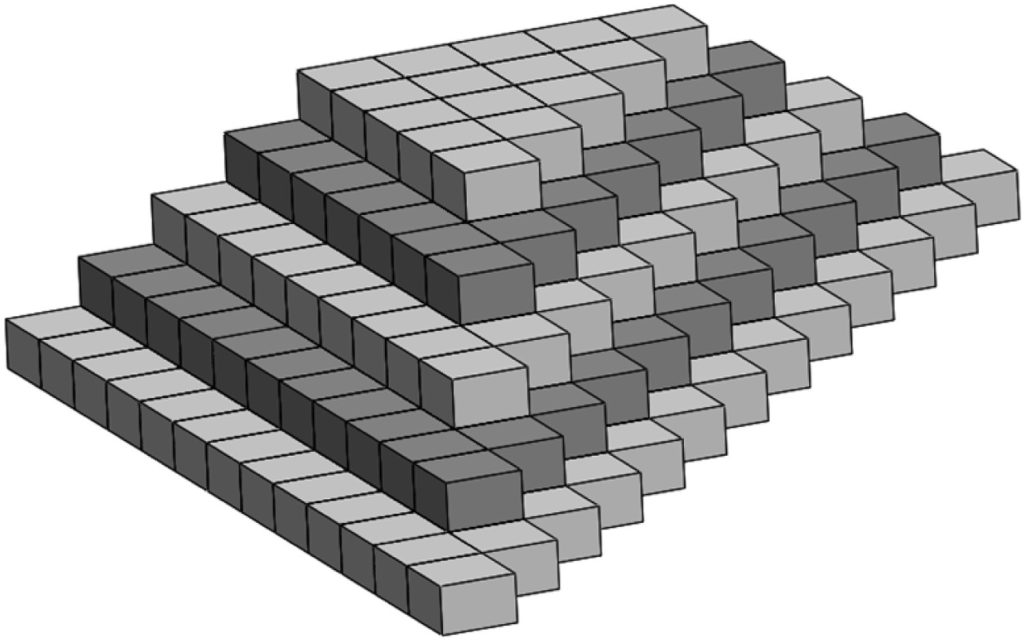

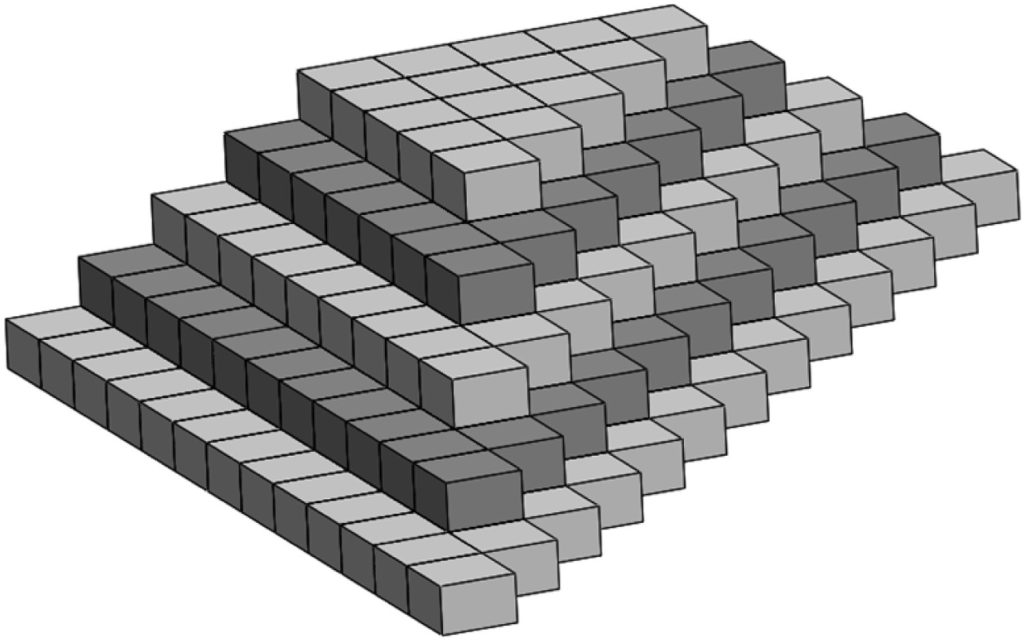

Materials extrusion introduced a unique defect profile, dominated by voids between deposited strands and poor interlayer bonding. Uneven extrusion charges produced under- and over-extruded areas, whereas excessive nozzle put on launched metallic inclusions and dimensional inaccuracies. Vertical construct orientations had been particularly susceptible to delamination, with bending assessments displaying as much as 50% power discount in comparison with horizontally printed specimens attributable to stresses performing perpendicular to layer interfaces.

In accordance with the authors, fracture origins may typically be traced again to a mix of pore morphology, floor topography, and loading orientation. “Whereas the beginning powders of ceramics produced by means of AM might be an identical, every technique introduces a attribute defect distribution within the ultimate half,” the researchers wrote. “Their power distributions are subsequently distinct, they usually can’t be thought-about the identical materials from a component-design perspective.”

Fractography proved to be a very efficient diagnostic instrument for failure evaluation, providing insights into defect formation mechanisms with out the excessive price of non-destructive imaging. Though computed tomography and in-situ inspection methods proceed to enhance, the research concludes that decision limits nonetheless stop dependable detection of smaller however crucial defects in dense ceramics.

Context inside ceramic additive manufacturing analysis

Fraunhofer IKTS has been a number one heart for lithography-based ceramic manufacturing (LCM) and Multi Materials Jetting (MMJ), each of which allow high-precision ceramic elements for industrial purposes. Earlier IKTS research confirmed the feasibility of multi-material ceramic printing but additionally highlighted challenges in reaching full density and powerful interlayer bonding.

Montanuniversität Leoben’s Division of Supplies Science has superior the mechanical characterization of 3D printed ceramics, linking fracture power to microstructural irregularities. Constructing on this basis, the current research introduces a standardized nomenclature to enhance cross-comparability amongst analysis teams and assist rising requirements equivalent to EN ISO/ASTM 52900:2021 and VDI 3405 for additive manufacturing.

Towards standardized understanding and course of enchancment

The authors suggest a taxonomy that teams defects by their course of origin: slicing, feedstock preparation, layer formation, shaping, cleansing, dealing with, contamination, gear put on, and environmental elements equivalent to humidity and temperature. Every supply introduces attribute defects, from floor aliasing and interlaminar voids to delamination and contamination-induced inclusions.

By mapping these relationships, the research establishes a foundation for systematic course of optimization. Researchers argue that figuring out defects early within the inexperienced physique—earlier than sintering—can information refinements in printing parameters, materials formulation, and dealing with protocols. Though full elimination of defects is inconceivable attributable to ceramics’ inherent brittleness, controlling their measurement and distribution is important for enhancing reliability. The authors counsel combining fractographic information with machine studying and in-situ monitoring in future work to foretell defect formation throughout manufacturing.

The findings present that process-induced defects are intrinsic to additive manufacturing, with every technique producing a definite sample of microstructural weaknesses that form half efficiency. By systematically classifying these defects, the research lays the groundwork for quantitative power modeling and defect-aware element design.

Assist form the 2025 3D Printing Business Awards. Join the 3DPI Knowledgeable Committee in the present day.

Prepared to find who gained the 2024 3D Printing Business Awards?

Subscribe to the 3D Printing Business e-newsletter to remain up to date with the newest information and insights.

Featured picture reveals Graphical summary. Picture by way of ScienceDirect.