Researchers from IMDEA Supplies Institute and the Technical College of Madrid have developed a design-focused strategy to enhance the efficiency of 3D-printed nitinol constructions. Their research, printed in Digital and Bodily Prototyping, demonstrates how woven, fabric-like architectures can improve the deformability of nickel-titanium alloys manufactured by means of additive processes.

Conventional 3D printing of nitinol has confronted important limitations in comparison with typical manufacturing strategies. Earlier research have proven that 3D-printed nitinol samples exhibit roughly half the deformability fee of industrially produced nitinol, with the additive manufacturing course of creating extra brittle supplies.

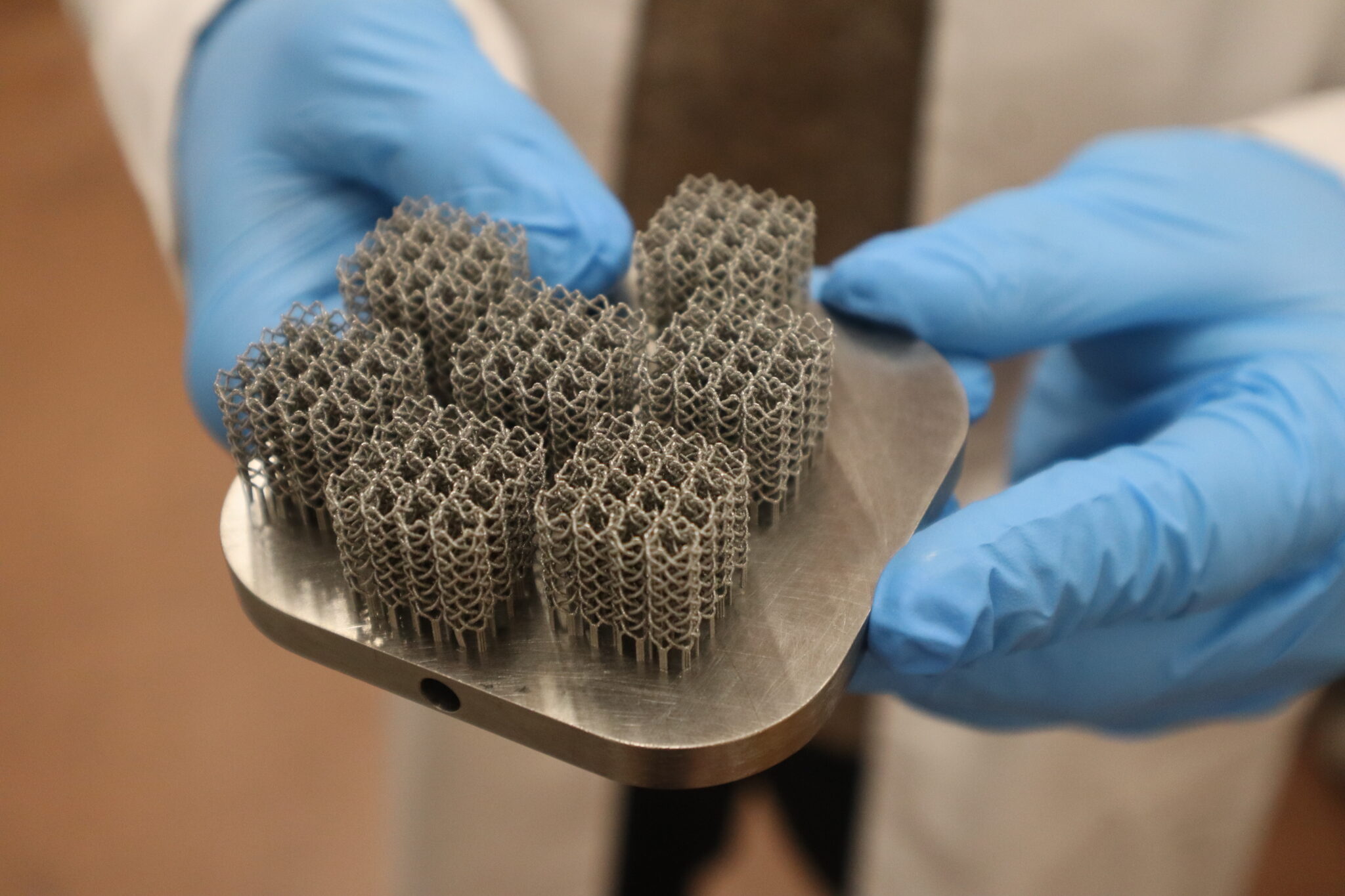

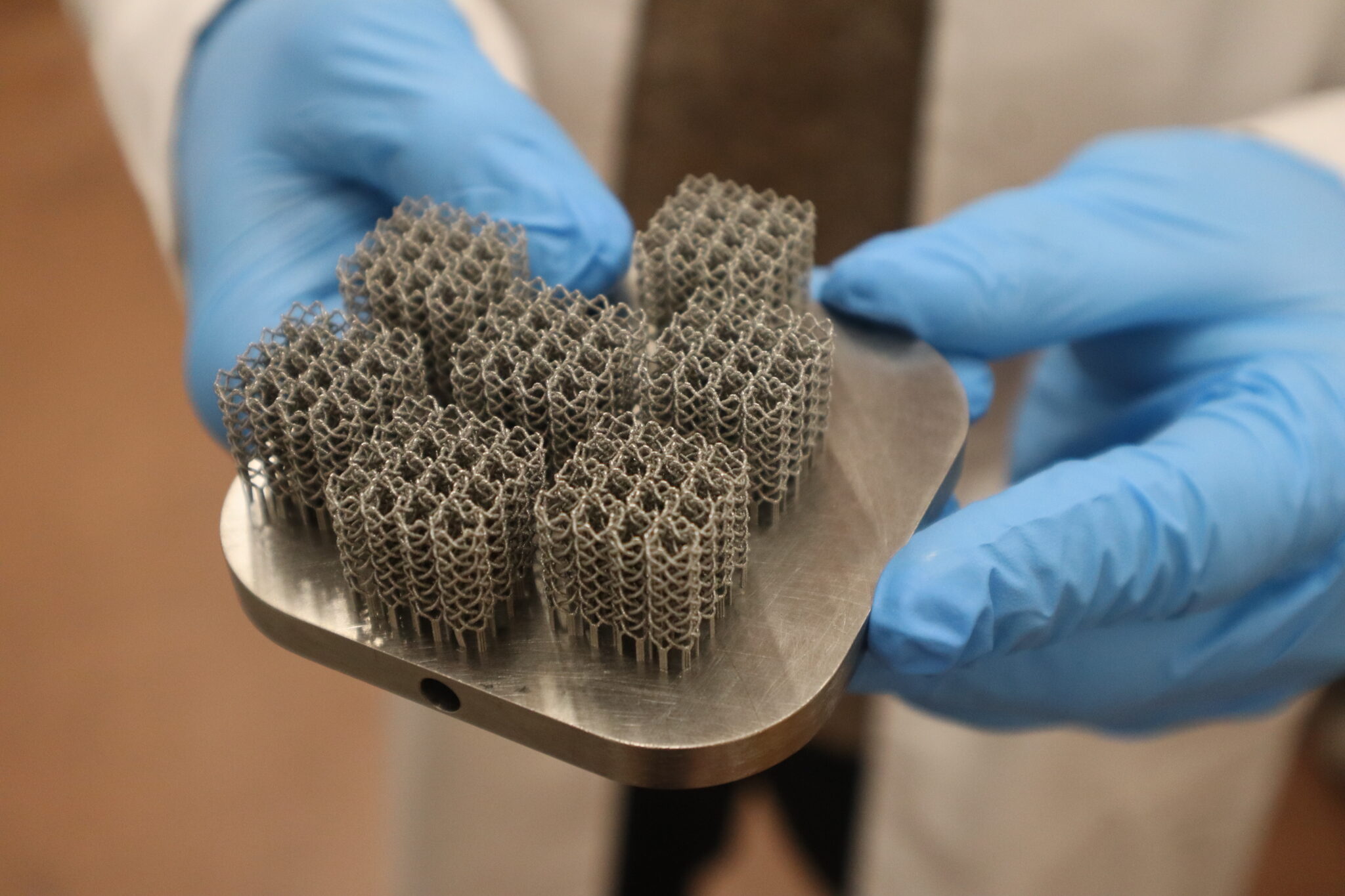

The analysis group addressed this problem by shifting focus from materials optimization to architectural design that amplifies mechanical efficiency by means of geometry. They created advanced woven constructions together with meshes, spheres, and rings utilizing laser powder mattress fusion strategies. “These have been a few of the most complex-shaped woven nitinol constructions ever created,” explains Prof. Andrés Díaz Lantada from UPM and IMDEA Supplies Institute.

The research launched an algorithm-based design framework particularly tailor-made for additive manufacturing of nitinol. Two predominant households of constructions have been developed: tubular lattices and cylindrical woven architectures. Mechanical testing revealed that the stiffness, load-bearing capability, power absorption, and toughness of those constructions will be adjusted throughout a number of orders of magnitude by means of design alone.

The analysis group used computed tomography to check printed samples with digital fashions, validating the accuracy of their manufacturing course of. This strategy confirms the methodology’s effectiveness for creating advanced, customizable architectures. The work was supported by the ‘iMPLANTS-CM’ undertaking funded by Comunidad Autónoma de Madrid.

Supply: supplies.imdea.org