A brand new optofluidic method to three-dimensional micro- and nanofabrication permits a variety of supplies to be assembled into complicated, purposeful microdevices.

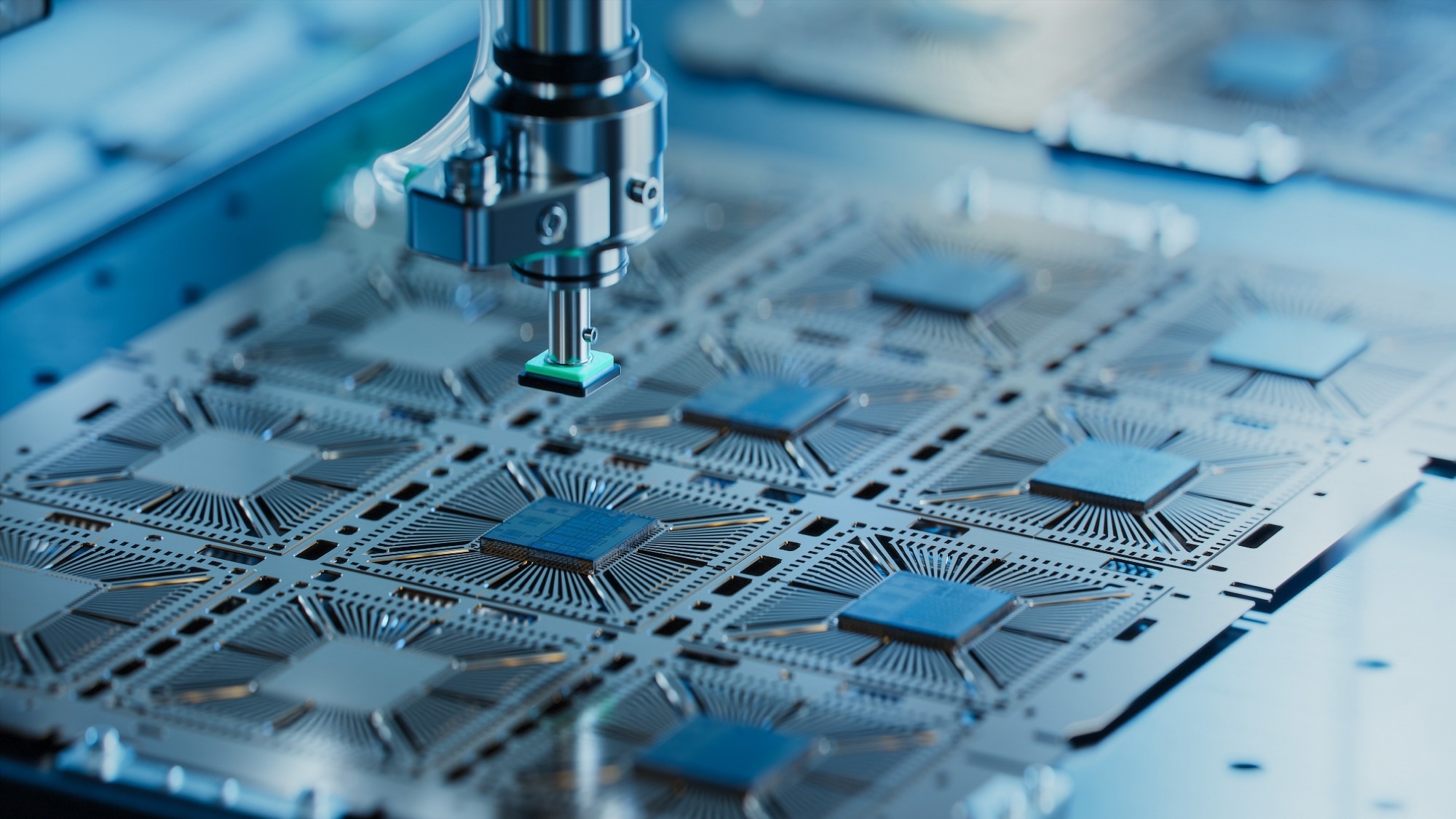

Examine: Optofluidic three-dimensional microfabrication and nanofabrication. Picture Credit score: IM Imagery/Shutterstock.com

Examine: Optofluidic three-dimensional microfabrication and nanofabrication. Picture Credit score: IM Imagery/Shutterstock.com

The crew demonstrates the method by constructing particle-based microfluidic valves able to quickly separating microparticles and nanoparticles by dimension, in addition to multi-material microrobots that reply to magnetic, optical, and chemical stimuli.

Revealed just lately in Nature, this method may sidestep long-standing materials limits in high-resolution 3D printing.

Get all the small print: Seize your PDF right here!

Three-dimensional micro- and nanofabrication methods underpin advances in microrobotics, microactuators, and photonic gadgets.

Amongst them, two-photon polymerization (2PP) has develop into a number one technique, valued for its sub-100-nanometre decision and skill to print intricate free-form buildings. Nonetheless, 2PP is basically restricted to crosslinking polymers, limiting the vary of purposeful supplies that may be fabricated instantly.

Researchers have tried to increase 2PP to non-polymeric supplies by engineering specialised photoresists. For instance, by chemically modifying inorganic nanoparticles or incorporating metal-coordination complexes.

These approaches, whereas efficient in particular circumstances, stay narrowly tailor-made and lack broad materials compatibility.

An alternate technique is direct materials meeting. Optical meeting strategies use light-induced forces or fields to govern particles suspended in resolution, however most present methods are confined to two-dimensional buildings and usually function at low throughput.

Utilizing Gentle-Pushed Circulate to Assemble 3D Buildings

The brand new technique combines 2PP with optofluidic meeting. First, a hole three-dimensional polymer template with a small opening, resembling a dice, is fabricated on a glass substrate utilizing 2PP.

The template is then immersed in a liquid containing uniformly dispersed nanoparticles or micrometre-scale particles.

A femtosecond laser, centered close to the template opening, domestically heats the fluid. This generates a pointy temperature gradient that drives a robust convective circulate, reaching speeds of a number of millimetres per second.

Carried by this circulate, particles are funneled into the hole template, the place they accumulate and assemble right into a three-dimensional construction outlined by the template geometry.

The researchers achieved an meeting charge of roughly 105 silica nanoparticles per minute. After meeting, the encompassing polymer template is eliminated utilizing gentle oxygen plasma therapy, abandoning a free-standing, particle-based 3D microstructure.

Physics Behind the Meeting

The meeting course of is ruled by a stability between inter-particle forces and fluid-driven drag. Enticing interactions between particles – described by DLVO concept – should be sturdy sufficient to beat hydrodynamic forces that are likely to disperse them.

The researchers present that this stability could be tuned by adjusting resolution circumstances. Rising ionic energy, for instance through the use of sodium chloride concentrations of 0.5 M or larger, screens electrostatic repulsion between particles and promotes clustering.

Meeting additionally requires the optofluidic circulate pace to stay beneath a crucial threshold, the place engaging forces can dominate over Stokes drag.

Laser heating performs a twin function. Along with buoyancy-driven convection, localized solvent evaporation can generate transient bubbles. These bubbles introduce Marangoni flows pushed by floor pressure gradients, additional accelerating particle transport into the template.

In consequence, volumetric meeting speeds of round 700 µm3 per second have been achieved, a lot sooner than typical 2PP printing charges.

Broad Materials Compatibility

As a result of the driving mechanism depends on light-induced fluid circulate reasonably than material-specific optical forces, the method is basically non-selective. The researchers assembled three-dimensional microstructures from a variety of supplies, together with metals, metallic oxides, diamond nanoparticles, nanowires, and quantum dots.

Regardless of the absence of chemical bonding or high-temperature sintering, the ensuing buildings stay mechanically secure. This stability arises from sturdy van der Waals interactions between densely packed nanoparticles, permitting the buildings to be self-supporting instantly after template elimination.

Multi-material architectures have been created utilizing sequential meeting steps, wherein totally different particle suspensions have been launched one after one other, with washing steps in between. This enabled exact spatial management over materials composition inside a single construction.

Microfluidic Valves and Microrobots

To show sensible performance, the crew fabricated microfluidic chips containing particle-assembled microvalves embedded inside polymer channels. These porous valves enable solvent to move by means of quickly whereas blocking nanoparticles above a dimension set by the valve’s inner pore construction.

By tuning valve dimensions and supplies, the researchers achieved size-selective separation and enrichment of nanoparticles.

The method was additionally used to construct microrobots composed of a number of purposeful supplies. By selectively integrating magnetic, catalytic, and photoactive nanoparticles, the researchers created microrobots able to tumbling below magnetic fields, transferring below ultraviolet gentle, or altering movement in chemical environments, generally inside the identical gadget.

A 3D Nano Printing Future

The optofluidic technique might be a path to fabricating really volumetric 3D micro- and nanostructures from supplies which can be tough or inconceivable to print instantly utilizing standard methods.

Whereas the present implementation depends on serial, laser-addressed meeting reasonably than parallel high-throughput manufacturing, it supplies a robust platform for integrating numerous supplies with exact spatial management.

The researchers recommend that the strategy might help future advances in colloidal robotics, microphotonics, catalysis, and microfluidic programs: Areas the place materials range and three-dimensional structure are important.

Journal Reference

Lyu X., et al. (2026). Optofluidic three-dimensional microfabrication and nanofabrication. Nature. DOI: 10.1038/s41586-025-10033-