In keeping with Montana Tech, its Mechanical Engineering division has just lately acquired greater than $1 million value of apparatus to reinforce its 3D printing capability. The tools contains an Xact Metallic system, two One Click on Metallic MPrint laser powder mattress fusion methods, and two MPURE energy dealing with methods.

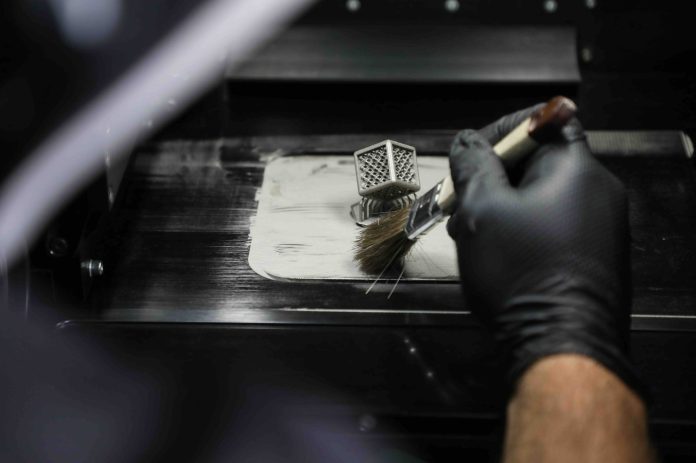

The mixed capabilities of all three items of apparatus – arriving between 2023 and 2024 and totaling greater than $630,000 – give Montana Tech Superior Manufacturing (MTAM) members the flexibility to print stainless-steel, titanium, and nickel-based alloys. Funding for the printers was obtained by a cooperative settlement with the Military Analysis Laboratory. Different current tools purchases embrace a $46,000 3D scanner and a $170,000 high-speed infrared digicam.

“We have now a number of the most interesting additive manufacturing capabilities within the space,” stated Affiliate Professor Dr. Nathan Huft, who leads the Montana Tech Superior Manufacturing (MTAM) Analysis Group with Dr. Peter Lucon.

A number of items of apparatus can be found to combine powdered alloys – together with a number of vibratory mixing machines that Lucon patented, and a powder rheometer.

The lab can be house to a 3D printer that may print polymers on a big scale of as much as 1.5m x 0.75m. One other printer can print specialised inks which might be used for circuit boards. 5 others can print resins.

“We actually attempt to give the scholars the flexibility to be taught the printer, as a result of they’ll’t do the analysis except they actually perceive,” stated Huft. “We encourage them to do their very own initiatives, as a result of if they only do the analysis they are going to by no means be taught what the printers are able to.”

Researchers from Montana State College in Bozeman have used the ability, and personal companies have additionally expressed curiosity in collaboration. Graduate scholar Emily Maynard is focusing her analysis efforts on testing the energy of the totally different printed elements as a part of a mission for the Naval Undersea Warfare Heart Division, in Keyport. One other graduate scholar, Layton Bahnmiller, just lately 3D scanned vintage elements and produced digital fashions for a neighborhood theater group’s historic theater seats. He then used the digital fashions to 3D print resin patterns for use by a foundry to solid metallic replacements.