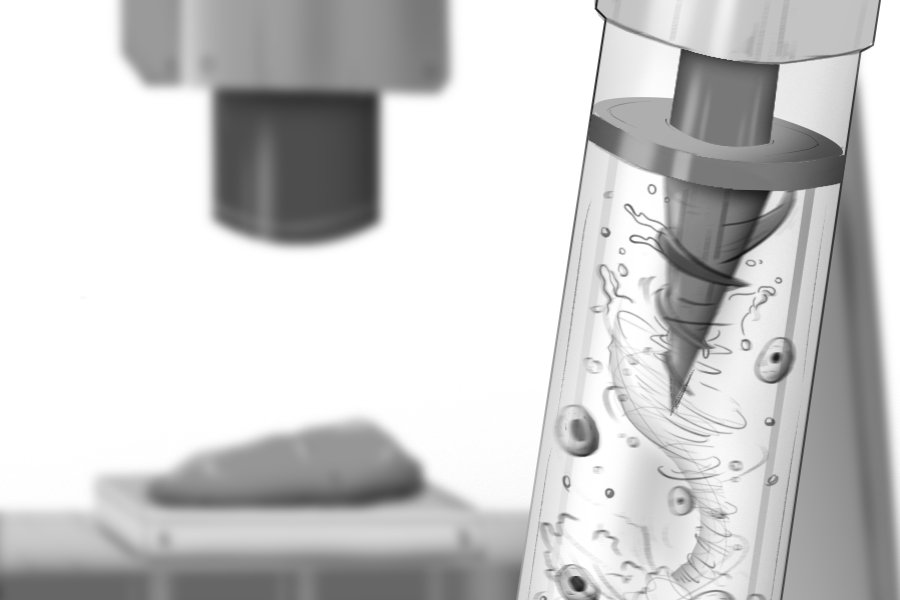

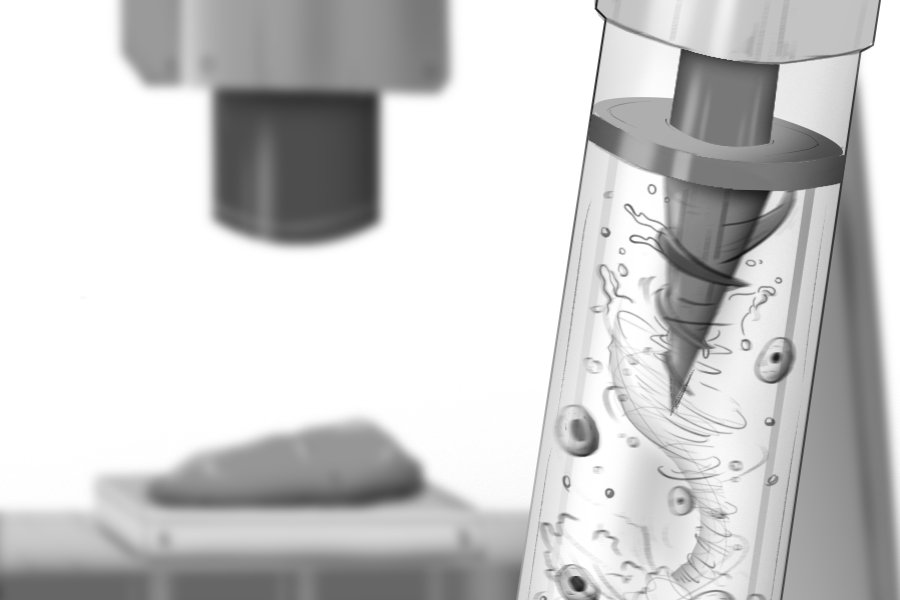

MIT researchers have developed a magnetic mixing system known as MagMix to handle a persistent problem in 3D bioprinting the place cells settle to the underside of printer syringes throughout lengthy printing periods. The system consists of a small magnetic propeller that matches inside bioprinter syringes and a everlasting magnet hooked up to a motor that controls the propeller’s motion. Revealed February 2 within the journal Machine, the examine demonstrates how this method maintains uniform cell distribution all through the printing course of.

“This cell settling, which turns into worse throughout the lengthy print periods required to print massive tissues, results in clogged nozzles, uneven cell distribution, and inconsistencies between printed tissues,” explains Ritu Raman, the Eugene Bell Profession Growth Professor of Tissue Engineering and assistant professor of mechanical engineering at MIT. Present options like handbook stirring or passive mixers can’t preserve uniformity as soon as printing begins, in keeping with the researchers.

Testing confirmed that MagMix prevented cell settling for greater than 45 minutes of steady printing throughout a number of bioink sorts whereas decreasing clogging and sustaining excessive cell viability. The staff used laptop simulations to optimize the propeller design and velocity, then validated the outcomes experimentally. As a proof-of-concept, researchers demonstrated that the system might print cells that developed into muscle tissues over a number of days.

The compact system may be mounted on customary 3D bioprinters with out altering bioink formulations or interfering with regular printer operations. Lead creator Ferdows Afghah, a postdoc in mechanical engineering at MIT, famous that “exact management over the bioink’s bodily and organic properties is crucial for recreating the construction and performance of native tissues.” The researchers consider improved tissue printing might help illness modeling, drug testing, and finally regenerative medication purposes.

The work was supported by MIT’s Security, Well being, and Environmental Discovery Lab (SHED), which focuses on translating biofabrication improvements from laboratory demonstrations to scalable purposes. “MagMix is a robust instance of how the best mixture of technical infrastructure and interdisciplinary help can transfer biofabrication applied sciences towards scalable, real-world impression,” says Tolga Durak, SHED’s founding director.

Supply: information.mit.edu