Might 2024 highlighted important progress throughout the additive manufacturing sector, significantly in protection functions and superior analysis.

The U.S. Division of Protection (DoD) centered on modernizing provide chains and enhancing weapon growth by means of partnerships with AML3D, 3YOURMIND, and Aerojet Rocketdyne. Battlefield-ready 3D printing techniques noticed elevated adoption, whereas analysis breakthroughs in supplies like tungsten and the GRX-810 superalloy expanded prospects in clear power and aerospace functions.

From humanitarian initiatives to developments in client items and high-performance printers, this month’s information underscored the various functions of 3D printing applied sciences.

Learn on for the highlights in Might 2024 from AML3D, NASA, College of Limerick, Hand-in-Hand, Fast Liquid Print, and extra.

U.S. DoD’s elevated AM adoption strengthens protection capabilities

Might 2024 introduced notable developments within the U.S. DoD’s use of 3D printing to deal with provide chain challenges and advance weapon growth.

Australian 3D printer producer AML3D secured an AUD$0.70 million (US$0.46 million) order from Laser Welding Options (LWS), a key provider to the U.S. Navy. Below this settlement, two ARCEMY Small Version 2600 3D printers will probably be leased for 12 months, with an choice to buy them outright, addressing U.S. DoD’s provide chain challenges through U.S. Navy’s submarines.

Together with technical help and software program licensing, this initiative aimed to reinforce LWS’s skill to qualify Nickel Aluminum Bronze (NAB) elements for submarine functions, constructing on an earlier ARCEMY 2600 system acquired in September 2023. Plans to airfreight the 3D printers from Adelaide to Houston had been set in movement, with operations anticipated to start inside 8 to 10 weeks.

Efforts to modernize logistics prolonged to the U.S. Military, the place 3YOURMIND partnered with the Fight Capabilities Growth Command (DEVCOM) Floor Automobile Techniques Middle (GVSC) to guage as much as 10,000 elements of the M113 armored personnel service for additive manufacturing.

Components had been analyzed for feasibility, value, and lead time to establish these most fitted for manufacturing. Working with Phillips Corp Federal Division, this transfer seeks to streamline logistics, help U.S. DoD’s objectives to reshore provide chains, and advance distributed manufacturing practices.

This mission additionally builds on a $100 million GVSC’s alliance with Wichita State College’s Nationwide Institute for Aviation Analysis (NIAR). Signed final 12 months, the entities developed a digital twin of the M113 and explored superior manufacturing methods, together with laser powder mattress fusion and directed power deposition.

In the meantime, L3Harris Applied sciences’ subsidiary Aerojet Rocketdyne secured a $22 million contract from the U.S. DoD to develop a 3D printed hypersonic propulsion system beneath the Rising Additive Manufacturing Maturity for Airbreathing Hypersonics (GAMMA-H) problem. Over a 36-month timeline, the corporate will deal with simplifying scramjet manufacturing workflows to deal with provide chain fragmentation, enhance effectivity, and cut back prices.

By advancing manufacturing strategies for hypersonic weapon elements, the initiative helps the Pentagon’s broader objectives of modernizing protection manufacturing and increasing hypersonic capabilities.

3D printing deployed on the entrance strains

3D printing information from Might 2024 additionally highlighted on-site manufacturing and restore of navy tools enabled by 3D printing.

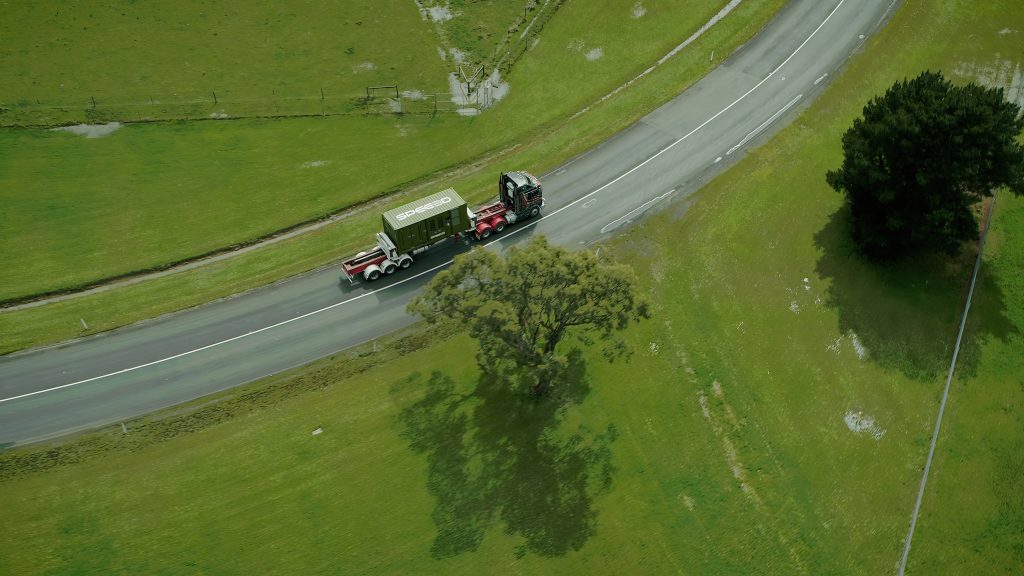

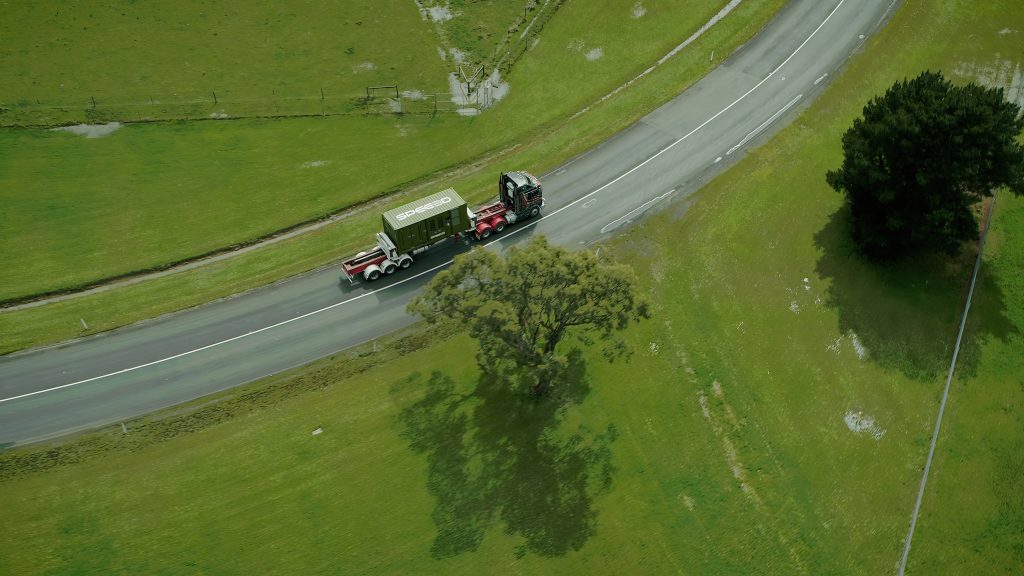

Australian metallic 3D printer producer SPEE3D launched the Expeditionary Manufacturing Unit (EMU), a cell 3D printing system combining its XSPEE3D printer and SPEE3Dcell post-processing unit. Designed for protection functions, the EMU permits navy forces to supply massive metallic elements on-site in distant environments, addressing provide chain challenges.

Developed by means of trials with the U.S., Australian, and British militaries, this technique makes use of Chilly Spray Additive Manufacturing (CSAM) to quickly fabricate sturdy elements with out lasers or inert gases. Submit-processing capabilities embody warmth therapy, machining, and testing, guaranteeing elements are prepared for speedy use. In accordance with the corporate, EMU’s portability and pace make it priceless for protection and industries like mining, oil, and gasoline.

The British Military introduced that it had deployed 3D printers within the area throughout NATO’s Steadfast Defender train. Below Venture Brokkr, the Military used the XSPEE3D chilly spray metallic 3D printer and a polymer system to supply automobile elements reminiscent of jerry can caps and communication brackets, addressing provide chain delays and bettering restore effectivity.

Positioned close to the frontlines in Germany and later showcased in Belgium, these moveable techniques enabled quick on-site manufacturing, with the XSPEE3D able to creating metallic elements in beneath an hour. This deployment lowered prices, minimized environmental affect, and boosted navy readiness. Future plans embody constructing digital design catalogs for fleets like BOXER and AJAX to broaden on-demand 3D printing capabilities.

Advances in 3D printing analysis

In Might 2024, analysis breakthroughs took middle stage together with a world-first growth.

Researchers at Seoul Nationwide College developed the blended FDM (b-FDM) methodology, a two-step course of enabling exact management over gradient materials properties in 3D printing. Utilizing customary FDM printers and filaments, the approach combines supplies right into a single digital materials (DM) filament, producing elements with numerous properties like power, conductivity, and coloration.

Demonstrations with an Unique Prusa i3 MK3S included stretchable conductive elements, foldable origami grippers with built-in sensors, and objects with as much as 36 coloration gradients. The low-cost, accessible methodology improves materials bonding and performance, opening new prospects for wearable electronics, engineering gadgets, and practical gradient supplies.

In the meantime, in a world-first, researchers from the U.S. Division of Power’s (DoE) Oak Ridge Nationwide Laboratory (ORNL) efficiently 3D printed defect-free tungsten elements with complicated geometries utilizing electron-beam additive manufacturing.

Produced at ORNL’s Manufacturing Demonstration Facility, these tungsten elements, able to withstanding temperatures above 180 million levels Fahrenheit (100M°C), are essential for clear power applied sciences like fusion power. Tungsten’s excessive temperature resistance makes it ultimate for reactors, providing important potential for sustainable, carbon-free power.

ORNL’s electron-beam 3D printing course of addresses tungsten’s brittleness by depositing layers in a high-vacuum atmosphere, lowering contamination and stress. This innovation helps the Division of Power’s renewable power mission, constructing on earlier developments in nuclear power techniques.

In one other important research, College of Limerick researchers studied how compression charges have an effect on the efficiency of metallic 3D printed honeycomb lattices. Utilizing materials extrusion (ME) and laser powder mattress fusion (LPBF), they discovered that compression pace influenced power absorption, yield, and stress, however not elastic modulus.

Smaller cell sizes in ME-printed honeycombs confirmed greater power however extra variability than laser powder mattress fusion (LPBF) elements. Deformation patterns various with compression pace, whereas thermal softening was additionally noticed. The research validated findings with empirical fashions and launched a predictive mannequin to optimize honeycomb constructions for aerospace and biomedical functions.

NASA’s GRX-810 superalloy enters industrial markets

Might 2024 additionally noticed aerospace materials innovation as NASA licensed its GRX-810 superalloy, a breakthrough 3D printable materials, to 5 American firms together with Carpenter Know-how Company, Elementum 3D, Linde Superior Materials Applied sciences, Inc., and Powder Alloy Company.

This information follows, US-based 3D printer OEM 3D Techniques efficiently verifying the properties of GRX-810 in April 2023, testing its high-temperature mechanical efficiency utilizing the Direct Metallic Printing (DMP) platform throughout numerous tools and processing parameters.

Developed at Glenn Analysis Middle, GRX-810 is twice as robust, a thousand occasions extra sturdy, and withstands temperatures over 2,000°F, making it ultimate for high-temperature aerospace and aviation functions. As a part of NASA’s Know-how Switch Program, the licensing agreements allow commercialization of the fabric, anticipated to scale back prices, enhance sustainability, and help energy-efficient engine growth whereas contributing to the US financial system.

Hand-in-Hand transforms lives with 3D printed prostheses

Serving to kids and underserved people, Florida-based Slice Engineering highlighted the humanitarian affect of 3D printing by recognizing Hand-in-Hand, a non-profit based in Egypt by childhood most cancers survivor Mohamed Hatab. This group creates free 3D printed prostheses, primarily for kids, to enhance the standard of lifetime of these with limb variations.

Assist from Slice Engineering has boosted Hand-in-Hand’s productiveness fivefold, enabling the environment friendly manufacturing of prosthetic limbs. Slice Engineering’s CEO Dan Barousse recommended the initiative as a significant instance of the business’s skill to drive optimistic change.

These excited about supporting Hand-in-Hand’s mission can contribute by means of a fundraising hyperlink.

3D printed golf irons redefine client items manufacturing

Additive manufacturing gained traction within the client items sector, aligning with tendencies in 3D Printing Trade on its increasing use in product manufacturing.

One standout instance of this development was the debut of Cobra Golf’s metallic 3D printed golf irons. In an interview, Cobra Golf executives Mike Yagley and Ryan Roach mentioned the brand new LIMIT3D providing, the world’s first commercially out there 3D printed metal golf irons.

Manufactured utilizing direct metallic laser sintering (DMLS) and designed with nTop software program, the golf equipment function inside lattice constructions that cut back weight by 100 grams, redistribute 33% of the clubhead’s mass, and decrease the middle of gravity (CG), bettering ball pace, accuracy, and forgiveness.

The 3D printing course of halved growth time, eradicated tooling wants for design changes, and enabled fast iterations, considerably lowering prices. Launched on June 7, 2024, with solely 500 units priced at $3,000, these golf equipment mix the feel and appear {of professional} fashions with enhanced accessibility.

Whereas conventional strategies stay dominant, Yagley and Roach see 3D printing taking part in an more and more necessary position in creating progressive, high-performance golf tools.

Eplus3D fuels metallic 3D printer ‘laser wars’ with EP-M2050

In Might 2024, Chinese language 3D printer producer Eplus3D unveiled its large-format EP-M2050 Laser Beam Powder Mattress Fusion (PBF-LB) 3D printer that includes 36 lasers as customary and improve choices to 49 or 64 lasers.

This introduction displays the continuing “laser wars” in metallic additive manufacturing, the place business leaders are shifting their focus towards multi-laser techniques for sooner, large-scale manufacturing as a substitute of emphasizing unit shipments.

With a construct quantity of 2050 x 2050 x 1100 mm (extendable to 2000 mm), this printer handles supplies like titanium and stainless-steel at speeds as much as 1080 cm³/h. It delivers over 99.9% half density, assembly aerospace requirements, whereas its open structure allows customizable parameters for optimum manufacturing.

Fast Liquid Print secures funding to broaden elastomer 3D printing

Shifting the main focus to elastomer 3D printing, Fast Liquid Print (RLP) made headlines in Might with its funding success. The spin-off from Massachusetts Institute of Know-how (MIT) secured $7 million in Sequence A funding led by HZG Group, with extra backing from BMW i Ventures and MassMutual. With the newest funding, RLP plans to scale manufacturing, develop its workforce, and discover new enterprise alternatives.

Identified for its gel-dispensing know-how, RLP allows the swift manufacturing of sentimental, recyclable elements throughout industries reminiscent of medical, automotive, and client items. By using reusable gel as a suspension, the method eliminates help constructions, minimizes post-processing, and facilitates large-scale printing in minutes. Traders have highlighted the know-how’s transformative potential in elastomer 3D printing and its numerous functions.

3D Printing Information Highlights from 2024: Improvements, Developments, and Evaluation

What 3D printing tendencies do the business leaders anticipate this 12 months?

What does the Way forward for 3D printing maintain for the subsequent 10 years?

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade publication or observe us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits The XSPEED in transit. Photograph through SPEE3D.