Your seat on the Additive Manufacturing Benefit awaits! Register free for AMA: Automotive & Mobility.

Swiss earmold merchandise producer Otoplastisches Centrum GmbH (OC GmbH) and German service supplier CADdent are making use of ceramic 3D printing to patient-specific earmold manufacturing.

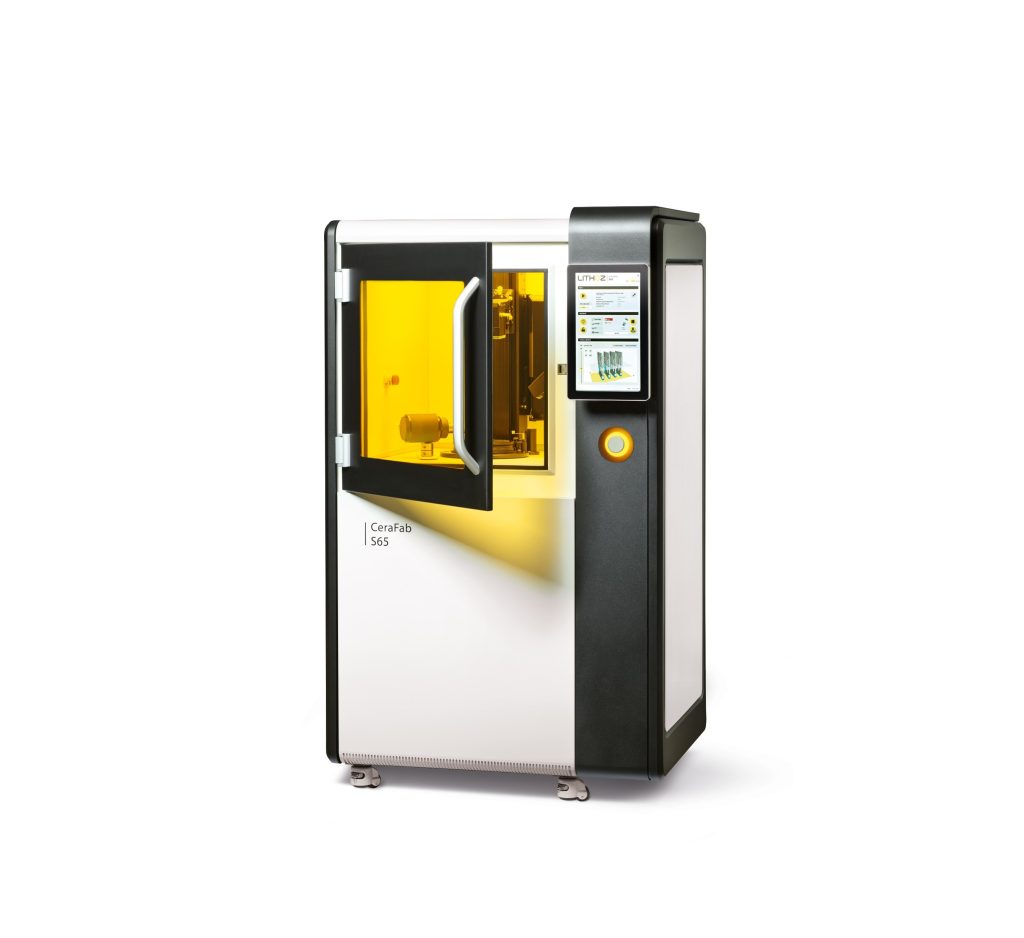

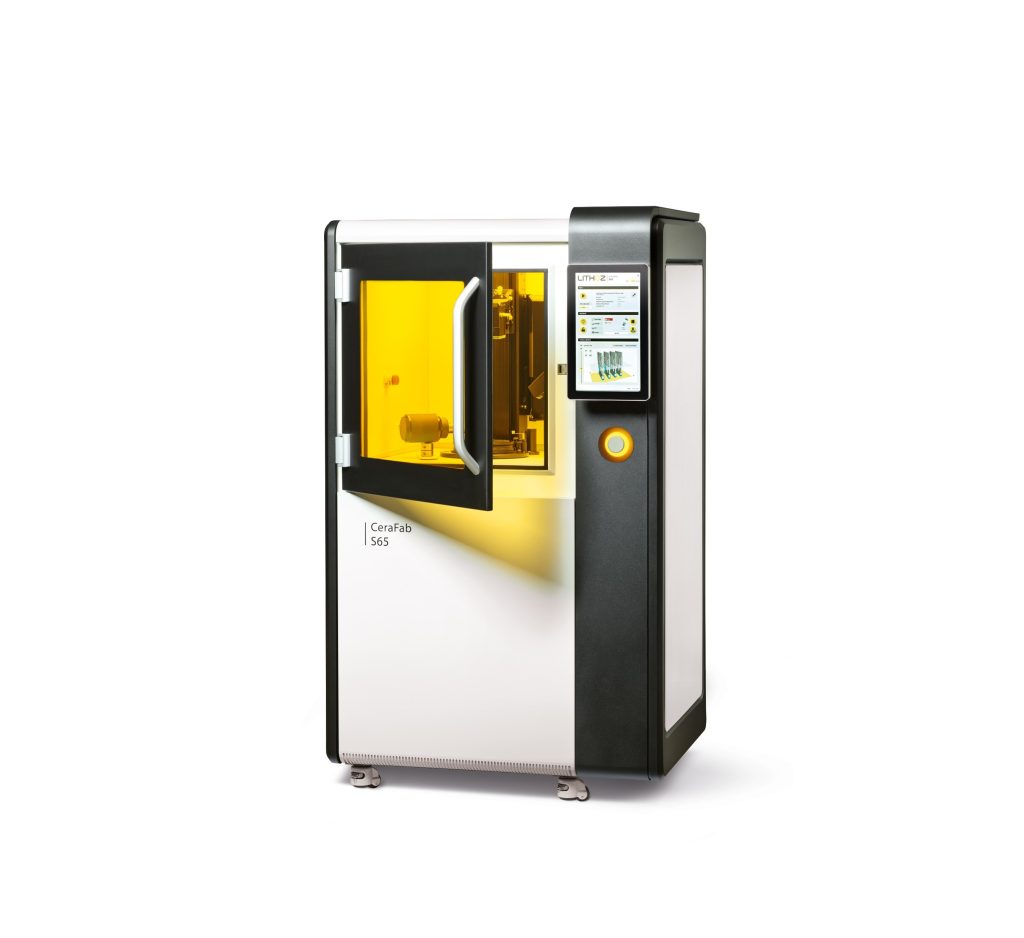

Utilizing Lithoz’s Lithography-based Ceramic Manufacturing (LCM) course of through the CeraFab S65 Medical 3D printer, the 2 corporations have demonstrated that earmolds constructed from alumina-toughened zirconia (ATZ) could be produced reliably at an industrial scale.

This course of achieves wall thicknesses beneath 1 mm and dimensional tolerances inside ±50 µm, whereas preserving the internal channels important for sound transmission. As a result of the elements bear stress-free sintering, they are often produced with out help constructions but stay steady, even in delicate geometries.

The strategy additionally exhibits potential for small-batch manufacturing, with as much as 15 ATZ earmoulds produced on a single construct platform. Outcomes point out compliance with biocompatibility requirements and alignment with necessities for patient-specific medical gadgets.

Ceramic earmolds developed via this strategy shall be offered at Formnext 2025 on the Lithoz sales space in Corridor 11.1, C35.

Jurij Belik, CEO of OC GmbH provides: “These technical achievements display the distinct benefits that ceramics supply for otoplastics. Not like polymers or titanium, ceramic earmoulds supply long-term biocompatibility alongside superior sturdiness and put on resistance. ATZ’s acoustic neutrality ensures uncompromised sound high quality, and the fabric’s aesthetic properties enable for customisable, high-value designs.”

Lithoz LCM expertise for medical functions

Ceramic 3D printing is nicely fitted to medication as a result of its biocompatibility and bone-like qualities enable for customized porous implants that encourage regeneration. It additionally permits quick, reasonably priced manufacturing of patient-specific instruments and fashions that enhance surgical effectivity and outcomes.

Consistent with this, Lithoz showcased a brand new stage within the improvement of its lithium disilicate dental 3D printing materials developed with Ivoclar from IPS e.max powder at LMT Lab Day Chicago 2024.

The fabric is designed for serial manufacturing of patient-specific restorations resembling crowns and veneers, combining exact match and pure translucency. Utilizing the CeraFab S65 Medical printer, as much as 50 restorations could be produced in a single run and as many as 350 in a day, with zero materials waste and an eight-fold effectivity achieve over standard strategies.

Earlier this yr, the ceramic 3D printer producer reported a 92% success charge in a five-year scientific follow-up research of beta-tricalcium phosphate (β-TCP) patient-specific implants produced with its CeraFab 3D printer.

Carried out between 2017 and 2018 with 14 sufferers aged 17 to 57 present process jaw surgical procedure for dysgnathia, the research discovered the implants prevented antegonial notching and supported bone regeneration via their porous construction, which confirmed robust osteoconductive and osteoinductive properties. No post-surgical problems had been noticed, suggesting 3D printed β-TCP implants made with LCM might function a dependable long-term answer for mandibular irregularities.

Ceramic 3D printing in medical sector

Past Lithoz, different innovators are additionally making use of ceramic additive manufacturing within the medical discipline.

In 2020, Syqe Medical turned to XJet’s Carmel 1400 additive manufacturing system, which makes use of NanoParticle Jetting (NPJ) expertise, to provide ceramic elements for medical gadgets. Utilizing ceramics supplied the warmth resistance and electrical insulation wanted for Syqe’s new take a look at facility, fixing points the corporate confronted with PEEK and standard strategies.

NPJ printing delivered advantageous particulars, clean surfaces, and constant accuracy, whereas soluble helps simplified post-processing. In keeping with Syqe, the system enabled sooner supply, simple design changes, and dependable repeatability, making ceramic additive manufacturing a sensible and environment friendly answer for its product improvement.

As analysis, scientists on the Skolkovo Institute of Science and Expertise developed a 3D printing methodology for ceramic bone implants utilizing Useful Illustration (FRep) modeling, which produced error-free designs with customizable porous constructions to assist tissue integration.

The implants had been printed on an SLA machine with a ceramic paste, adopted by debinding and sintering to type their last construction. Assessments confirmed pore sizes between 440 and 700 µm, near the optimum vary for cell progress, and compressive power of 400 MPa, corresponding to trabecular bone. Ten prototypes had been ready for animal testing to evaluate scientific potential.

Assist select the 2025 3D Printing Trade Awards winners – join the Knowledgeable Committee now!

To remain updated with the newest 3D printing information, don’t overlook to subscribe to the 3D Printing Trade publication or comply with us on LinkedIn.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits ceramic 3D printed earmold lineup. Picture through Lithoz.