In response to Renishaw’s Chris Dimery, two key boundaries are limiting the adoption of additive manufacturing: excessive value per half and costly capital investments. At Formnext 2024 Dimery, Additive Manufacturing Enterprise Supervisor for the EMEA area, defined how the corporate’s new 3D printers handle these crucial challenges.

Through the Frankfurt-based commerce present, the British engineering agency unveiled its RenAM 500D sequence, including the 500D, 500D Flex and 500D Extremely to the RenAM portfolio of laser powder mattress fusion (LPBF) programs. These new industrial steel 3D printers incorporate two 500 W lasers right into a 250 mm x 250 mm x 350 mm construct quantity.

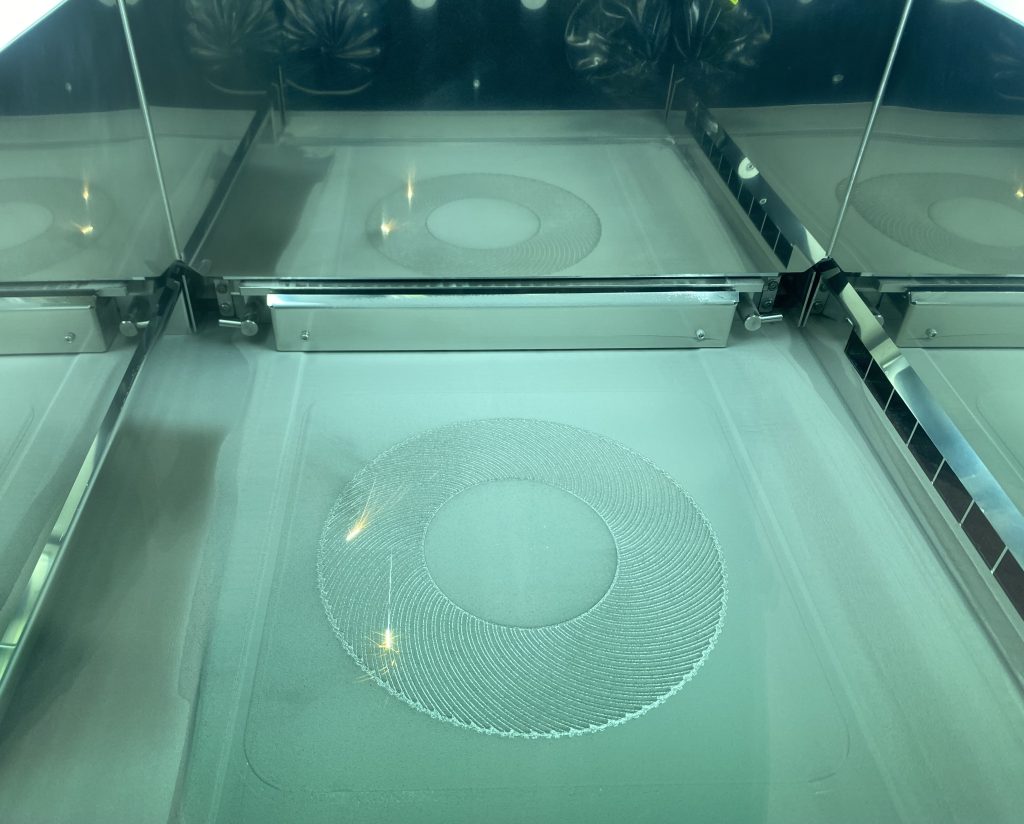

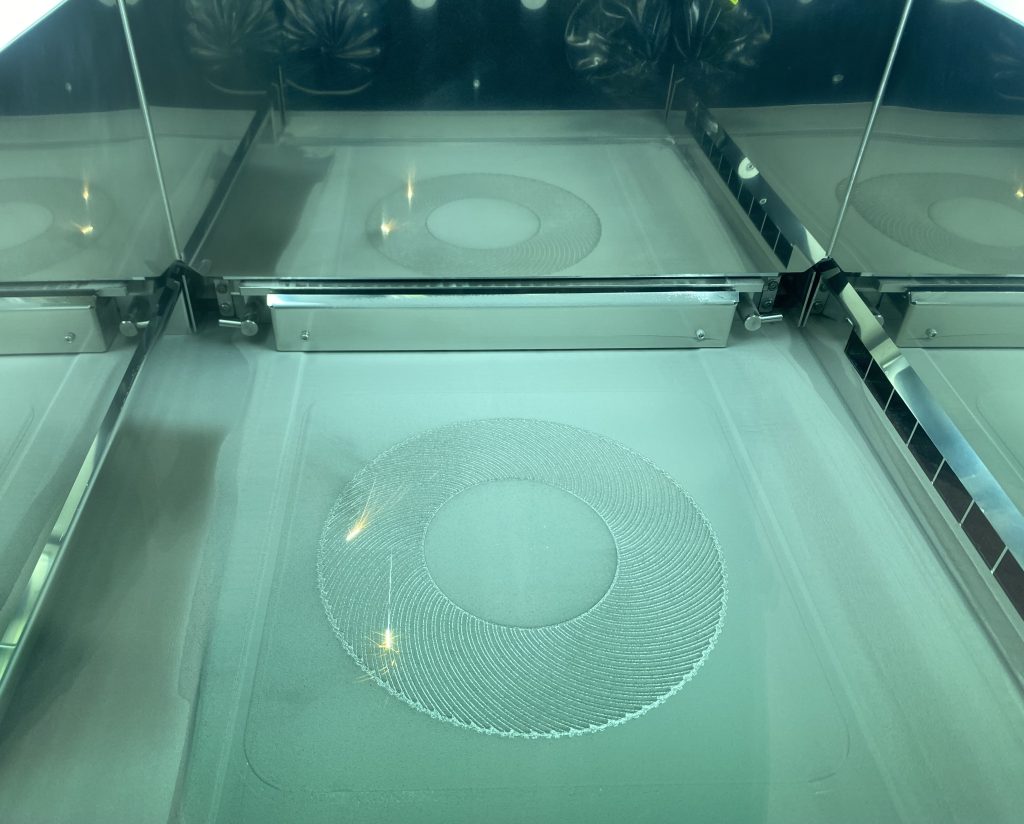

In a dialogue with 3D Printing Trade, Dimery outlined how Renishaw’s new choices steadiness productiveness and upfront funding, addressing rising market demand for versatile and cost-effective steel 3D printers. He emphasised the worth of Renishaw’s “game-changing” TEMPUS know-how, which is obtainable on the 500D Extremely mannequin. Dimery defined how TEMPUS reduces cycle instances by as much as 70% by firing each lasers whereas the powder recoater is transferring.

Renishaw’s Formnext sales space featured a number of actual buyer functions, together with 3D printing use circumstances for the medical, automotive and vitality sectors. It additionally showcased Crew GB’s observe bike used within the 2024 Olympic Video games, which options elements 3D printed on the corporate’s RenAM 500Q four-laser steel 3D printer.

New additions to the RenAM sequence

The RenAM 500D provides to Renishaw’s 500 sequence of 3D printers which incorporates the single-laser 500S and quad-laser 500Q programs. The brand new system seeks to deal with the necessity for a extra reasonably priced steel 3D printer which retains good productiveness, Dimery defined. “We’ve listened to the market and have tried to reply,” he added. The goal is to decrease boundaries to adoption whereas sustaining aggressive cost-per-part metrics, crucial for industries trying to combine additive manufacturing into manufacturing workflows.

The 500D sequence retains the sturdy core options of its predecessors, equivalent to superior fuel move administration, onboard powder recirculation choices, and course of monitoring instruments. One other key characteristic is Renishaw’s proprietary optical module and galvanometer (Galvo). This management mechanism ensures laser protection of your entire construct plate, which means customers “don’t have any limitations when it comes to sections or quadrant throughout the construct plate.”

Dimery expanded on how Renishaw differentiates from the competitors. One key issue is the corporate’s TEMPUS recoating know-how, provided on the RenAM 500D Extremely mannequin. The method permits the lasers to fireplace throughout recoater actions, saving as much as 9 seconds per construct layer. This interprets to a few instances quicker manufacturing speeds in comparison with single laser programs.

Dimery referred to as TEMPUS a “time-saving know-how,” and one of many Renishaw’s “largest developments” of current years. He added that it eliminates non-productive time by “maximizing the laser time of every layer within the construct.” Time financial savings are geometry-dependent. Whereas sometimes cycle time financial savings are round 30%, sure well-matched geometries can save as much as 70% with TEMPUS.

In response to Dimery, this enhance in productiveness interprets to decrease value per half, selling the adoption of Renishaw’s additive manufacturing know-how over typical manufacturing strategies. He added that the person half prices are “aggressive for lots of industries.” This provides to the RenAM 500D’s “very aggressive pricing for machine capability and footprint dimension.” Dimery defined that the brand new RenAM 500D Extremely gives 30% common time financial savings for round 15% greater funding prices.

Lifting the lid on buyer functions

At commerce exhibits, firms usually face limitations on the elements they will show on account of buyer confidentiality and non-disclosure agreements (NDAs). To handle this, many produce demonstration elements that are showcased in place of the particular merchandise.

Renishaw’s sales space, alternatively, was brimming with real-world, buyer functions. Dimery believes this serves as a “testomony to how profitable Renishaw is.” He added, “It’s nice to see that various firms are keen to share with the general public area that they’re partnered with Renishaw.”

One such companion is Mott Company, a filtration and move management engineering specialist based mostly in Farmington, Connecticut. Dimery outlined how Mott has used design for additive manufacturing (DfAM) to attain efficiency advantages over elements produced with typical manufacturing strategies. Moreover, the agency lately bought a RenAM 500S Flex 3D printer to scale back machine turnaround and setup instances by over 50%.

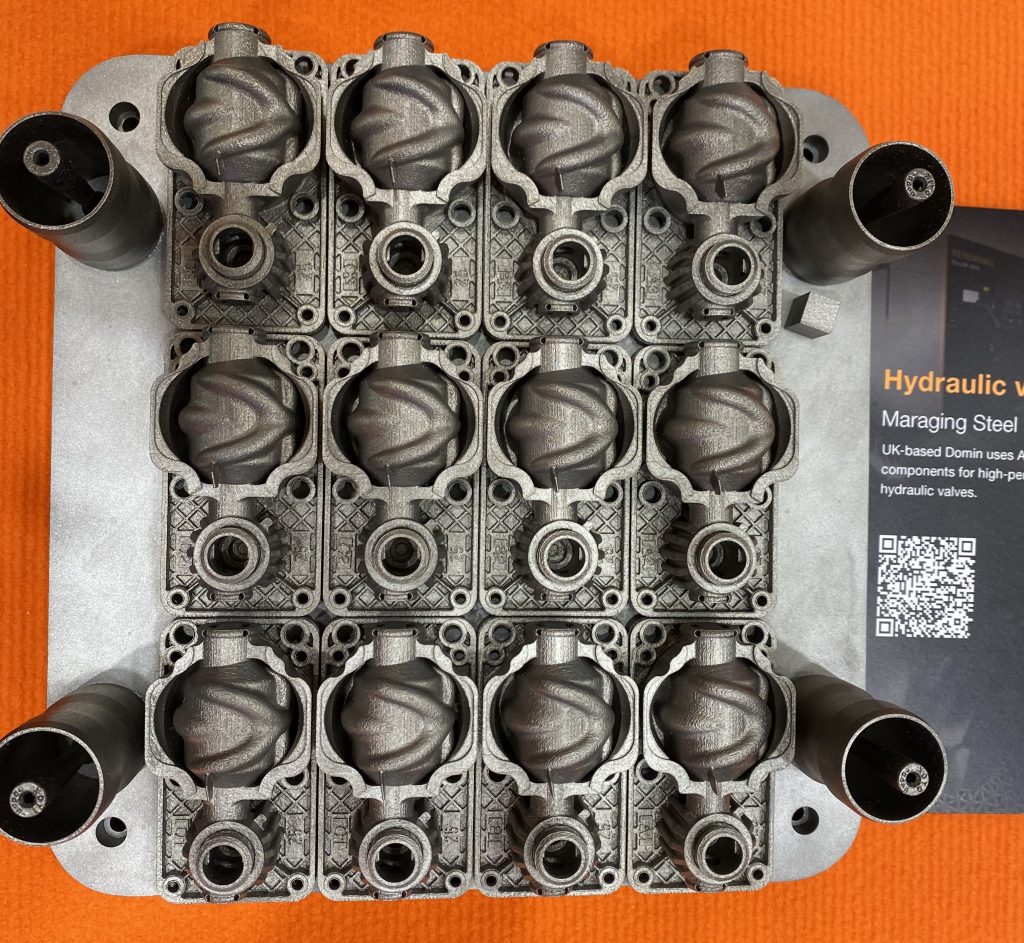

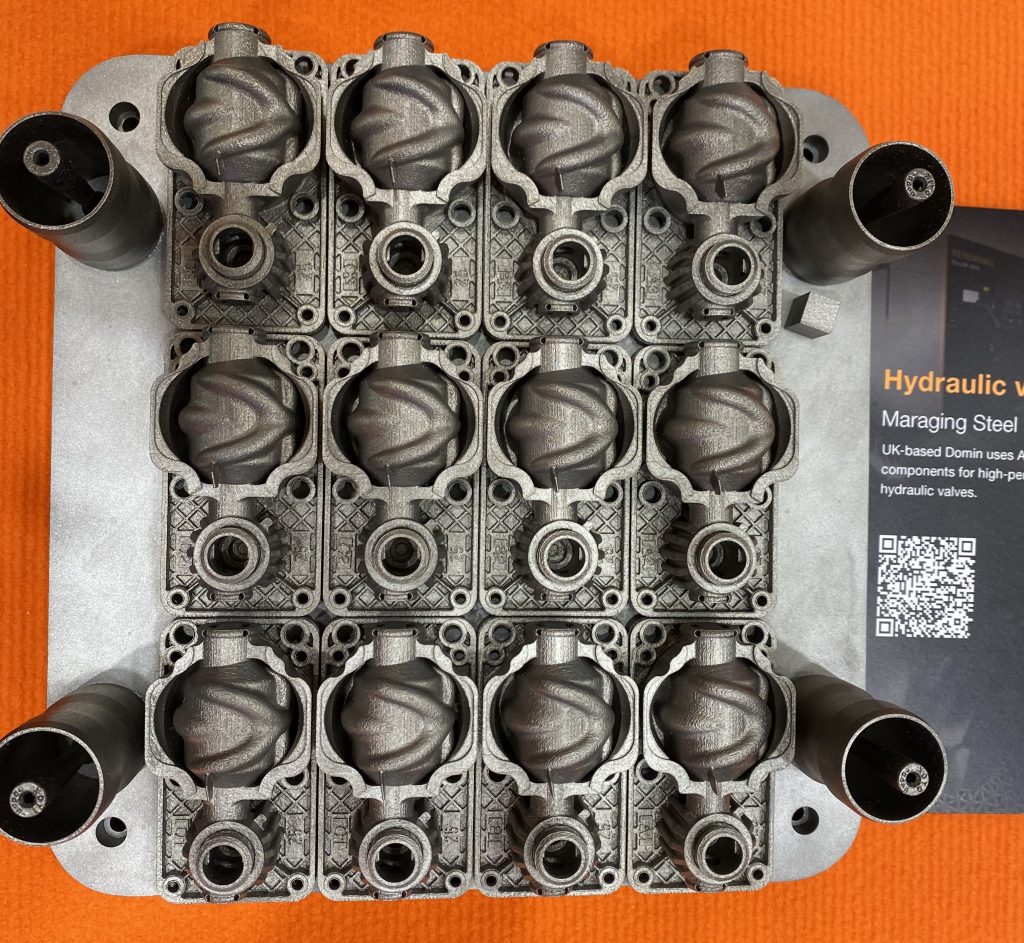

One other firm current on the Renishaw sales space was Bristol-based Domin, which showcased its 3D printed servo proportional hydraulic valves. The agency lately acquired a RenAM 500Q Extremely 3D printer, including to its current RenAM 500Q system bought in 2023. Renishaw’s know-how reportedly permits Domin to attain advanced geometries with inside options for automotive, aerospace and manufacturing functions.

Domin’s strategy combines additive manufacturing with high-speed motor management, fashionable electronics, massive information, and related know-how. It hopes it will assist scale back one gigatonne of hydraulics-related CO2 emissions by the tip of the last decade. Moreover, the Renishaw sales space featured a number of 3D printed automotive elements produced on the RenAM 500Q by the Basque engineering agency Madit.

Dimery emphasised that Renishaw’s know-how “actually comes into its personal” for medical and dental functions. A number of patient-specific 3D printed craniomaxillofacial implants from KLS Martin had been displayed on the sales space, showcasing the flexibility to attain manufacturing runs of elements with skinny partitions.

The preferred utility on the sales space, nonetheless, was Crew GB’s gold medal-winning racing bike. Renishaw labored with British Biking to 3D print over 1,000 elements for 32 Olympic observe bikes utilizing the RenAM 500Q. These elements included aerodynamic cranks, dropouts, seat keep bridges, and seat posts. Notably, the cranks characteristic an inside lattice construction. Its weight and form are optimized for “true efficiency” on the observe. The design was additionally created with cost-effectiveness in thoughts. “Being part of that venture was a extremely thrilling alternative for us,” added Dimery. “We collaborated to essentially push the boundaries when it comes to design.”

Renishaw and the way forward for 3D printing

Trying forward, Dimery believes the way forward for 3D printing depends upon the know-how’s capacity to resolve real-world challenges and ship worth. He highlighted two crucial drivers of development, the primary being application-driven adoption. “In case you are producing a part that’s cheaper utilizing one other manufacturing technique, why print it?” Dimery requested.

As an alternative, the Additive Manufacturing Enterprise Supervisor anticipates preliminary development for functions which profit essentially the most from the design freedom provided by additive manufacturing. He pointed to orthopedic implants that includes inside lattices that may’t be produced every other manner as one such utility.

One other driver of development, based on Dimery, would be the bettering cost-efficiency and productiveness features of 3D printing. As the fee per half decreases on account of diminished cycle instances, additive manufacturing turns into extra viable for a wider vary of industries. Dimery believes this shift will decrease boundaries to adoption, permitting extra firms to embrace the know-how.

He additionally emphasised the significance of schooling in driving market growth. “The data of additive manufacturing is rising as extra individuals undergo academic applications. That is crucial for firms to really feel assured of their funding choices.”

In the end, Dimery shared a optimistic outlook for the 3D printing trade. He acknowledged it’s tough to foretell what the longer term will deliver. Nonetheless, he believes there may be “one factor we might be sure of” for the approaching decade: “The client base goes to anticipate manufacturing prices to grow to be cheaper.” By lowering cycle instances, boosting productiveness and optimizing cost-per-part, Dimery believes Renishaw is well-positioned to deal with this demand.

All of the information from Formnext 2024.

Who’re the leaders in additive manufacturing? Vote now within the 2024 3D Printing Trade Awards!

Wish to share insights on key trade developments and the longer term 3D printing? Register now to be included within the 2025 3D Printing Trade Government Survey.

What does the way forward for 3D printing maintain?

What near-term 3D printing developments have been highlighted by trade consultants?

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the most recent 3D printing information.

You too can comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits the brand new RenAM 500D Extremely 3D printer from Renishaw at Formnext 2024. Picture by 3D Printing Trade.

![[INTERVIEW] Introducing Renishaw’s New RenAM 500D 3D Printers [INTERVIEW] Introducing Renishaw’s New RenAM 500D 3D Printers](https://i2.wp.com/3dprintingindustry.com/wp-content/uploads/2024/11/The-new-RenAM-500D-Ultra-3D-printer-from-Renishaw-at-Formnext-2024.-Photo-by-3D-Printing-Industry-scaled.jpg?w=696&resize=696,0&ssl=1)