Satellites, protection techniques, and next-generation semiconductors all push supplies to their limits. Metals falter underneath excessive warmth and stress, which is why engineers flip to superior ceramics. But producing them at scale has remained the problem.

With automation, AI-driven course of management, and built-in recycling, ceramics 3D printing OEM and course of supplier 3DCeram Sinto’s C1000 FLEXMATIC is designed to maintain manufacturing working with out compromise. It’s a semi-automated stereolithography printer constructed as a manufacturing system slightly than a prototyping instrument, with a construct platform of 320 × 320 × 200 mm that gives room for each giant structural elements and finely detailed elements.

Automation modules help steady operation, whereas a recycling unit captures and reconditions unused slurry in order that back-to-back builds could be carried out effectively with minimal waste.

AI-driven management for constant output

On the middle of the machine’s workflow is CERIA, 3DCeram’s proprietary synthetic intelligence (AI) suite. CERIA takes over the complicated job of setting print parameters, robotically producing the optimum situations for every job. By doing so, it reduces the trial-and-error that sometimes slows manufacturing, shortens ramp-up phases, and lowers the training curve for operators.

Simply as importantly, it ensures that half high quality stays constant throughout repeated cycles. For producers, this implies not solely reliability but additionally value effectivity, addressing one of many main obstacles that has saved ceramic additive manufacturing from wider industrial use.

What makes the C1000 FLEXMATIC much more vital is its capacity to course of superior nitrides. Aluminium nitride (AlN) stands out for its excessive thermal conductivity, glorious electrical insulation, and remarkably low thermal enlargement.

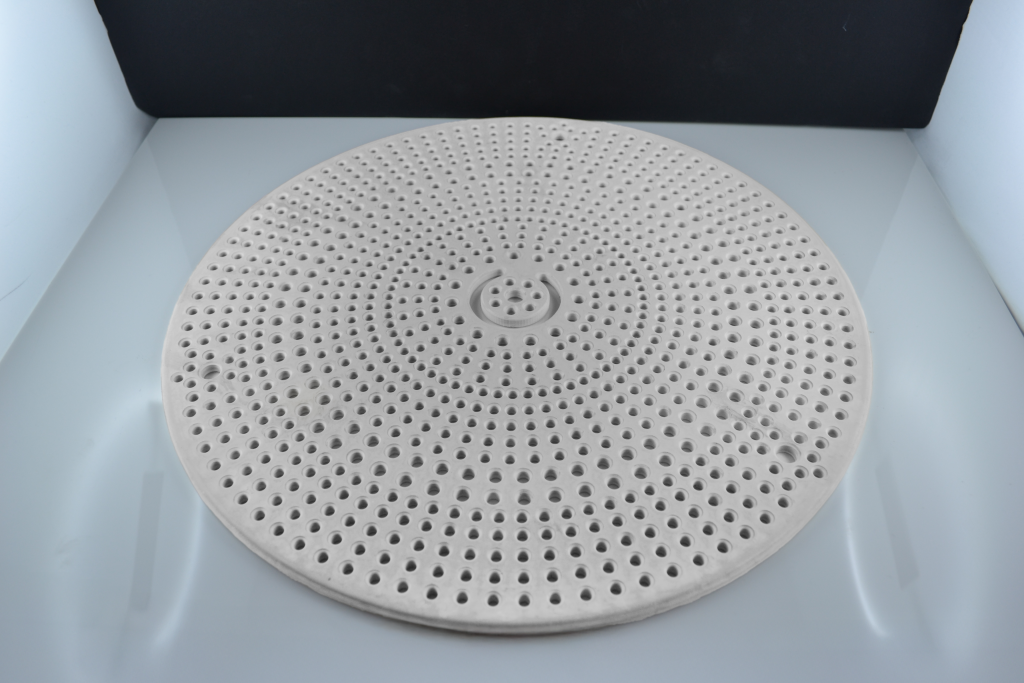

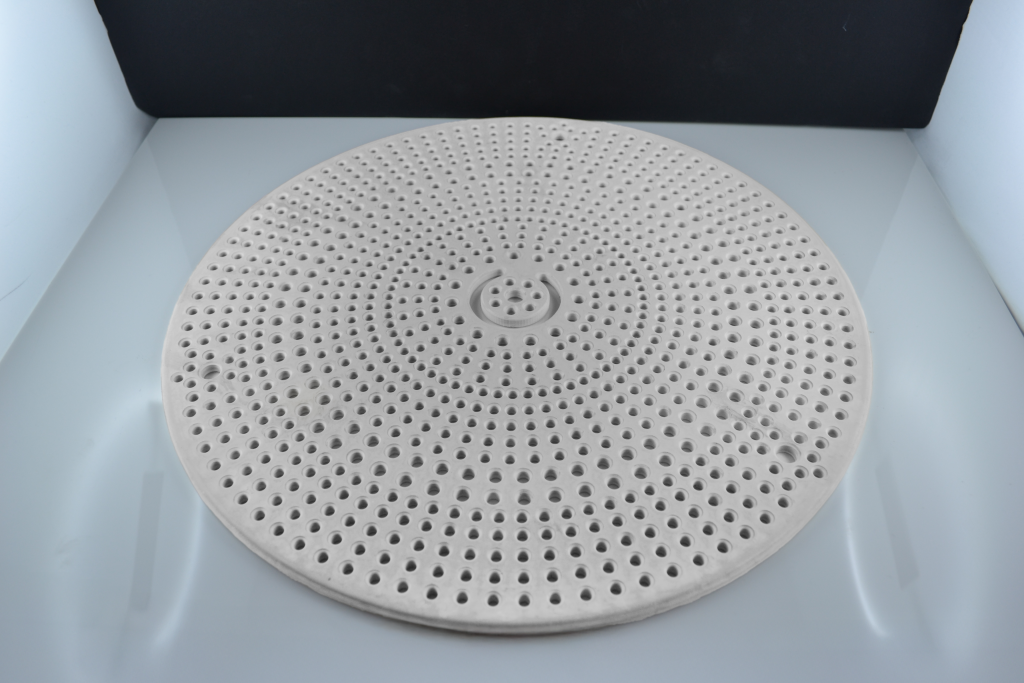

These qualities make it important for functions reminiscent of semiconductor manufacturing tools like warmth sinks, end-effectors, chuck tables, and many others, energy electronics, and warmth spreaders the place efficient thermal administration is crucial. Silicon nitride (Si₃N₄), then again, combines excessive fracture toughness and flexural power with resistance to thermal shock, put on, and corrosion.

These traits clarify its function in aerospace and protection, the place it’s used for satellite tv for pc helps, engine elements, armor, and radomes, that should endure each mechanical stress and excessive temperatures. By making these nitrides printable at industrial volumes, the C1000 FLEXMATIC closes the hole between materials potential and manufacturing feasibility.

Increasing superior ceramic AM into crucial industries

The benefits of the C1000 FLEXMATIC attain throughout a number of industries, every of which advantages otherwise. In aerospace, AlN permits light-weight thermal administration techniques, whereas Si₃N₄ is already being thought-about for spacecraft buildings and propulsion parts.

In protection, Si₃N₄’s toughness makes it appropriate for protecting armor and insulating elements that should carry out underneath sudden thermal shifts. In semiconductors, AlN substrates have gotten indispensable as gadgets generate larger warmth, and the C1000 FLEXMATIC makes it attainable to supply them in custom-made geometries and at volumes aligned with industrial demand.

One of many system’s novel qualities is its flexibility, which permits the identical platform to maneuver from producing intricate digital substrates to giant structural aerospace elements. This versatility reduces the necessity for a number of machines and lowers capital funding.

As a result of the printer is semi-automated and guided by the AI CERIA, even non-specialist operators can obtain dependable outcomes. This accessibility is vital to transferring ceramic additive manufacturing out of analysis environments and into mainstream factories, whereas the recycling station reinforces effectivity by minimizing waste and supporting steady, cost-efficient manufacturing.

For ceramic additive manufacturing to realize full industrial adoption, three situations should be met: scalable machines, high-performance supplies, and processes that align with industrial economics.

The C1000 FLEXMATIC meets all three. Having mixed automation, AI, recycling, and the flexibility to course of AlN and Si₃N₄, it presents producers a platform able to producing mission-critical elements for semiconductors, aerospace, and protection.

Ceramic additive manufacturing has typically been seen as a know-how of the longer term. With the C1000 FLEXMATIC, that future has develop into an industrial actuality.

Don’t miss the possibility to find the C1000 FLEXMATIC at Formnext 2025 — Corridor 11.1, Stand C68.

To remain updated with the most recent 3D printing information, don’t neglect to subscribe to the 3D Printing Business publication or observe us on LinkedIn.

When you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture exhibits electrostatic chuck for semiconductors. Picture through 3DCeram.