Learn to design and 3D print personalised wall fixtures to arrange and show all of your favourite issues.

Posted on October 16, 2017

by

Alec Richter

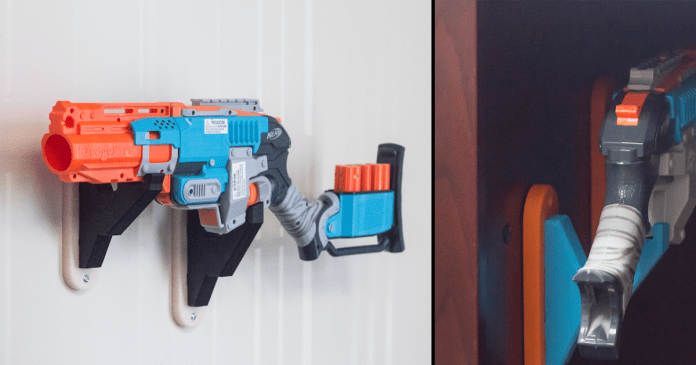

Across the workplace, Nerf blasters are liked and carefully guarded. Impromptu skirmishes are a daily incidence and arms races are alive and properly. You might have the very best blaster that Nerf has, however give it a pair months and Nerf has one thing even greater and badder than earlier than. On this battlefield, I have to be on the able to strike again or strike first. With the assistance of some 3D modeling and 3D printing, I’ve mounted my blasters each above and hidden underneath my desk – it was very easy to design and assemble these mounts. Let’s put together for conflict and develop some mounts in your arsenal. This course of will work with any merchandise that you simply’d wish to see displayed in your wall, or, you understand, hidden discreetly underneath your desk.

Try another weekend builds right here.

Step 1: Establish the Goal – What Do You Need To Mount

Normally, any “gun rack” or mount goes to be a primary hook sufficiently big to suit any blaster, which works, but it surely’s boring. To take advantage of safe match mount, particularly in case you’re mounting a blaster with 4 D batteries in it above your PC like I did, you might want to make a customized becoming to carefully maintain the contours of the blaster. Considered one of our Product Affiliate’s, Matt, has a Sledgefire Nerf that didn’t have a mount, so I’m going to design one for his blaster.

Step 2: Reconnaissance – Establish the Finest Place for Your Mounts to Grip

You’ll want to work out the place could be the very best place for the mounts to grip. Within the case of the Sledgefire, I do know that some individuals like to go away the inventory unattached (Matt), whereas others preserve it commonplace with the inventory put in (different Matt). Understanding that, I would like the mounts to grip in the identical place on each so it’s a normal mount. For earlier mounts I’ve used a set of calipers to measure and carefully estimate how extensive and the way lengthy the options of the blaster is. This works pretty properly, however I’ll admit there are most likely higher methods to do it. You might most likely use a contour gauge, however I understand how to make use of my useful calipers, in order that’s what I’m going to indicate you.

A contour gauge with the complicated form of the Sledgefire=E2=80=99s grip.

Step 3: Develop a Plan – Measure and Sketch Your Object

I figured the very best place to hint for the mount is underneath the barrel and under the set off guard, so I took the mandatory measurements and transferred them onto some notepads round a really exaggerated sketch so I had an thought of what the ultimate form ought to type of appear to be.

I made some fast strains to get me began on the contour of the blaster.

Step 4: Start Modelling – Match the Mount to Your Object

Beneath the barrel, it has a posh cross-section, so I’ll mannequin the holder into that form, however the grip of the blaster has a easy cross-section. I might make it a holder that’s completely sq., however the place’s the enjoyable in that? I took some extra measurements throughout the assorted edges of the blaster to get sufficient reference factors to form it in Solidworks.

All these dimensions are used to constrain the mannequin into the precise form.

Step 5: Check Match and Iterate Your Design

For the primary iteration, I made it with none clearance so it matches the blaster as carefully as it will probably. As an alternative of printing all the holder and discovering out it doesn’t match, I solely printed sufficient to see the place I must trim or broaden contours. Every of those was sufficient to see that I might prolong the grip only a tiny bit to extra securely lock into it, and the entrance wanted to be a bit wider to suit across the barrel and a bit shorter so it will probably slide straight again and miss the fake bolts.

This model was a bit too tight in some spots and a bit too unfastened in others.

Step 6: Design for Ease of Meeting

After a pair extra iterations, taking materials away in some spots and including materials in others, I had a form that match fairly properly to each components of the blaster. For the “arm” that extends out of the wall, I’ve a standardized form that up to now has match even the widest of blasters. To make it simpler to put in on the wall and never need to drill across the arm, the thickness of this complete half is particularly designed so the pegs have simply the correct amount of clearance the place they are going to match tightly into the wall half and never want any glue to maintain it in place. Our PRO Sequence Gentle Blue PLA is remarkably near the identical blue that Nerf used for the Sledgefire, and the Ultimaker Orange PLA is the brightest orange that matches fairly carefully to the Nerf security orange coloration. The opposite set was requested in PRO Sequence Pearlescent PLA and PRO Sequence Black PLA.

Assembled in items to make mounting simple.

That’s all there may be to it! Considered one of these was mounted immediately into the aspect of the desk for fast draw, and the opposite was mounted above the desk. You may adapt this to make customized pegboard holders, TV stands, whiteboard marker holders, or the rest that should repair towards the contours of an object.

I hope that this text was informative and has impressed you to create your individual Nerf wall mounts with the assistance of 3D printing. The varied mounts that I’ve designed are actually within the MatterHackers’ Design Retailer, and I might be updating if I create extra fashions for the remainder of the workplace.

Is there one thing you’d wish to see Alec create utilizing 3D printing? Tell us within the feedback under, or ship an e-mail to assist@matterhackers.com.