RAIN Pure Mountain Spring Water runs a fast-moving beverage operation. A number of SKUs, tight flooring area, and rising demand put strain on their end-of-line staff. The largest bottleneck was handbook palletizing. Operators had been lifting 30-lb circumstances at six per minute, typically reaching 100,000 lbs per shift. Throughput relied on human endurance, and the pressure was including up.

When handbook palletizing holds the road again

RAIN confronted acquainted challenges for mid-sized beverage producers:

- Labor-intensive duties: Two operators stacked heavy corrugated circumstances all shift lengthy.

- SKU complexity: Extra product variations elevated the chance of stacking and labeling errors.

- Restricted area: Conventional palletizing gear was too massive for his or her facility.

Even with engineering experience in-house, constructing a customized palletizer would have meant lengthy lead occasions and better threat.

A compact, ready-to-run repair

RAIN chosen the Robotiq PE20 Lean Palletizer, powered by a collaborative robotic from Common Robots. The system delivered the pace and reliability they wanted—with out main format modifications.

Key benefits for RAIN:

- Small footprint that match their current line

- Built-in security scanner that lowered guarding necessities

- Quick deployment with minimal downtime

- Simple programming, even with out robotics expertise

Founder Mark Majkrzak summed it up merely:

“This answer improves throughput, operator well being and security, gross manufacturing and labor utilization. All with out anybody shedding their job.”

Turning heavy lifting into high-value work

Automation didn’t exchange RAIN’s staff; it elevated them.

The 2 operators beforehand devoted to palletizing now maintain forklift certifications and help higher-value areas of the plant.

In the meantime, the PE20 runs persistently and retains tempo with manufacturing. RAIN obtained:

- Fast throughput positive aspects

- A safer, extra ergonomic workflow

- A faster-than-expected ROI

What this implies for beverage producers

RAIN’s expertise displays a sample throughout the Meals & Beverage trade. Compact cobot palletizers take away probably the most bodily demanding end-of-line process. They scale with SKU modifications. They match the place conventional techniques can’t. And so they ship ends in weeks, not months.

If you wish to see whether or not palletizing automation is sensible in your facility, begin right here.

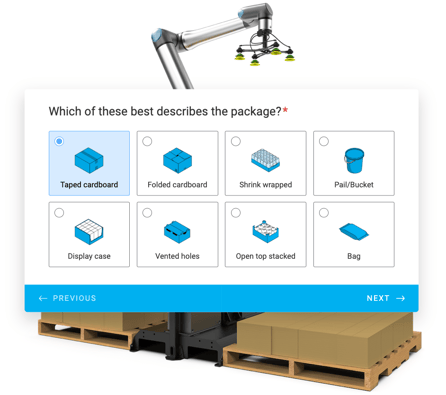

Attempt the Palletizing Match Software — a fast, interactive solution to see if Lean Palletizing is the suitable match in your line.

Need extra tales from actual factories like yours?

Comply with Robotiq on LinkedIn and be a part of over 75,000 producers seeing how automation retains individuals protected, and manufacturing operating sturdy.