Beauty producers are below rising strain to scale output. New product launches, shorter lifecycles, non-public labels, and seasonal demand are stretching manufacturing groups skinny. On the similar time, labor shortages and rising prices are making it tougher to employees end-of-line operations reliably.

For a lot of producers, the bottleneck isn’t filling, labeling, or packaging. It’s palletizing.

That’s why extra beauty producers are turning to collaborative robotic (cobot) palletizing as a sensible, scalable method to enhance throughput—with out rebuilding their crops or locking themselves into inflexible automation.

The top-of-line problem in cosmetics manufacturing

Palletizing stays one of the vital guide and labor-intensive steps in beauty manufacturing. In lots of services, it nonetheless requires:

- One operator per line

- A number of shifts per day

- Repetitive lifting and twisting

On the similar time, cosmetics producers face a uniquely complicated working atmosphere:

- Excessive SKU selection

- Frequent carton and pallet sample adjustments

- Restricted ground house close to manufacturing strains

Conventional industrial palletizers wrestle right here. They’re usually outsized, costly, and designed for lengthy runs of similar merchandise—situations that don’t mirror immediately’s cosmetics operations.

Why cobot palletizing works in high-mix cosmetics environments

Cobot palletizing flips the standard automation mannequin.

As an alternative of counting on one massive, centralized palletizer, producers can deploy compact palletizing cells straight at every manufacturing line. This decentralized strategy suits the realities of beauty manufacturing.

Key benefits embody:

Flexibility

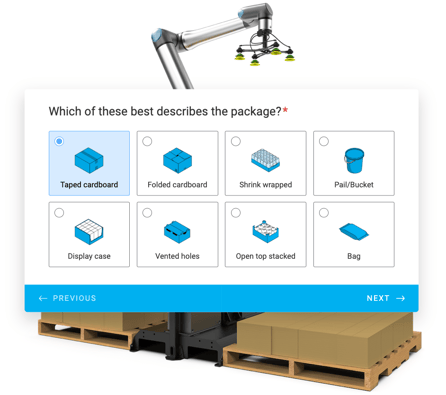

Cobots deal with a number of SKUs, field sizes, and pallet patterns with minimal reconfiguration. Recipe adjustments don’t require skilled programmers or lengthy downtime.

Compact footprint

Designed for tight end-of-line areas, cobot palletizers combine simply into current layouts with out main facility modifications.

Ease of operation

Operators can handle pallet adjustments and fundamental changes with minimal coaching—essential in environments with frequent employees rotation.

Decrease deployment danger

With no heavy fencing or complicated infrastructure, cobot palletizing is quicker to put in and simpler to justify internally.

For a lot of cosmetics producers, that is the primary time automation feels achievable reasonably than disruptive.

Quick ROI with out over-automation

Return on funding is a significant driver behind cobot palletizing adoption.

In a typical cosmetics facility:

- Palletizing requires one operator per shift

- Strains usually run two or three shifts

- Labor prices scale linearly with manufacturing

By automating palletizing on the line stage, producers can usually attain payback in 12 to 24 months, whereas conserving capital funding aligned with actual manufacturing volumes.

As an alternative of committing to a single, high-cost system upfront, they will:

- Begin with one line

- Validate efficiency

- Increase automation progressively

This strategy reduces monetary danger and avoids over-automation—an necessary consideration in fast-changing beauty markets.

A scalable mannequin for rising product portfolios

Beauty manufacturers evolve continuously. New codecs, new packaging, new SKUs.

Cobot palletizing helps that actuality via modularity and repeatability. As soon as an answer is validated on one line, it may be replicated throughout:

- Further manufacturing strains

- New product households

- Future plant expansions

This creates a standardized automation mannequin that grows with the enterprise, reasonably than constraining it.

Supporting folks whereas scaling manufacturing

Cobot palletizing isn’t about changing employees—it’s about utilizing expert labor the place it issues most.

By eradicating repetitive end-of-line duties, producers can:

- Cut back bodily pressure and damage danger

- Enhance consistency and pallet high quality

- Reassign operators to higher-value roles

As labor availability turns into much less predictable and product complexity continues to rise, cobot palletizing is more and more seen not as non-compulsory—however as a strategic enabler of sustainable development in cosmetics manufacturing.

Is cobot palletizing the correct match on your beauty manufacturing line?

Not each line has the identical necessities. Payload, cycle time, SKU combine, and out there house all matter.

Use Robotiq’s Palletizing Match Device to rapidly assess whether or not cobot palletizing is sensible on your operation and what a sensible deployment might appear to be on your facility.

Need extra tales from actual factories like yours?

Comply with Robotiq on LinkedIn and be a part of over 75,000 producers seeing how automation retains folks secure, and manufacturing working robust.