The 3D Printing Trade Assessment of the Yr continues with the largest tales from February.

Following information of cost-cutting and streamlining initiatives final month, February noticed firms face monetary challenges. Shapeways and Uniformity Labs auctioned off belongings, whereas Desktop Steel fundraising efforts continued with a mixed-shelf providing. On a extra constructive be aware, Core Industrial Companions raised substantial capital investments to increase its additive manufacturing portfolio.

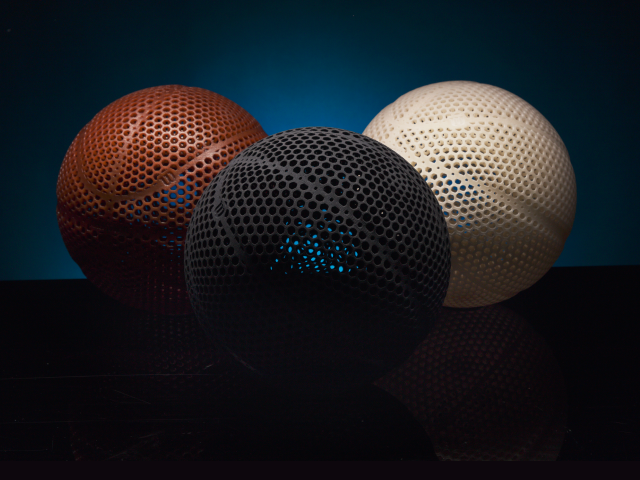

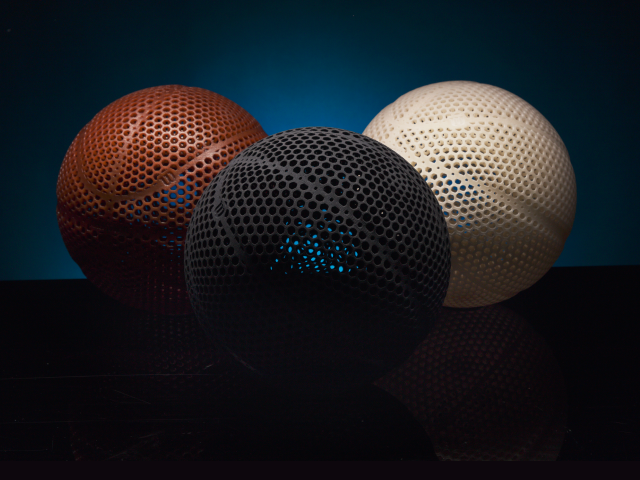

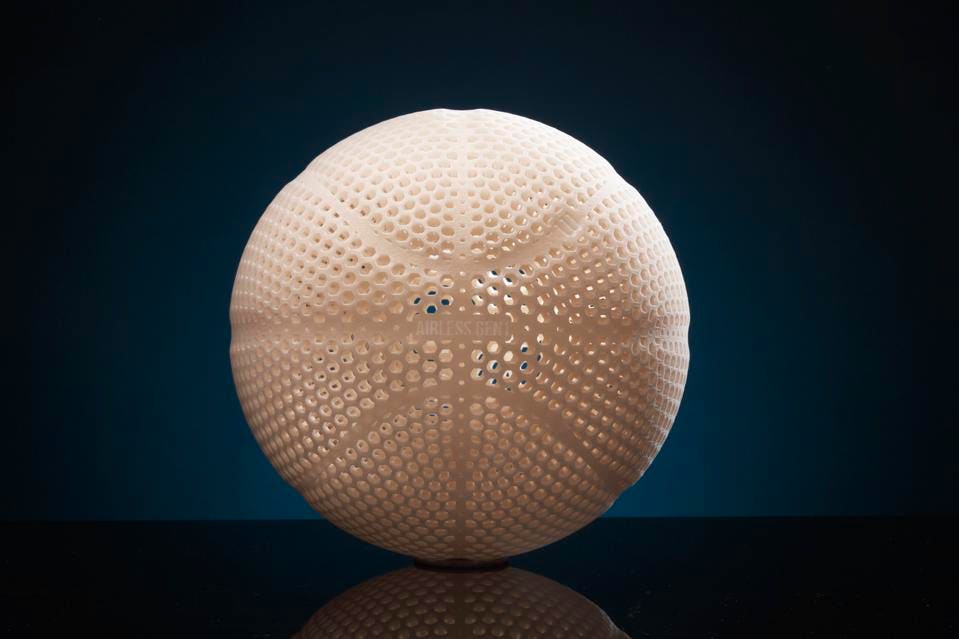

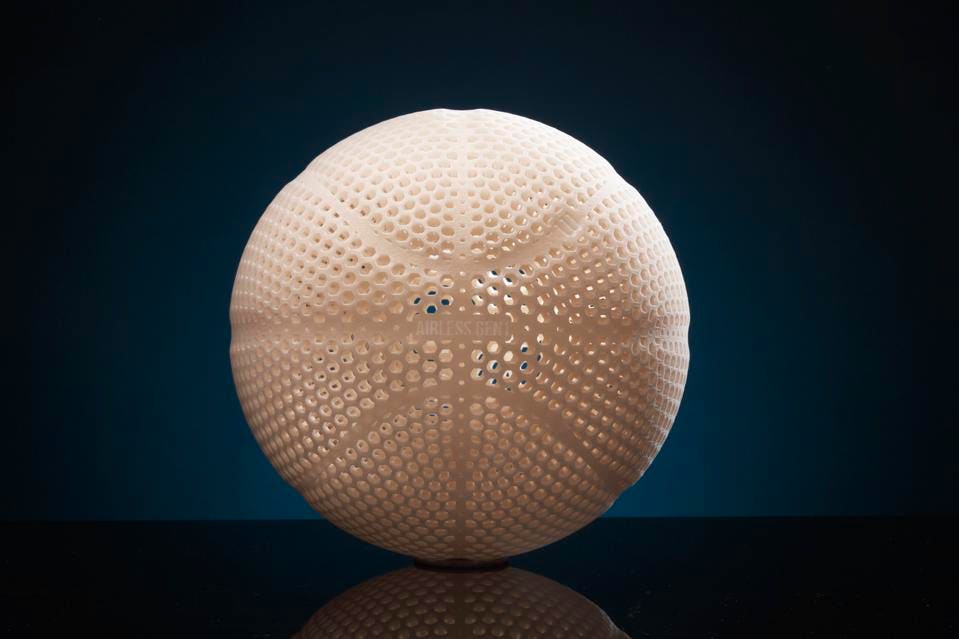

In different information, firms launched 3D printed shopper merchandise to handle end-market wants. Wilson’s 3D printed basketballs hit the cabinets, whereas additive manufacturing featured prominently inside the bike market. Additionally in February, 3D Printing Trade reported how Oracle Crimson Bull Racing makes use of additive manufacturing to spice up efficiency on the monitor. Elsewhere, a SpaceX rival efficiently launched a 3D printed rocket, whereas researchers achieved breakthroughs for 3D printing mind tissue and multi-color additive manufacturing.

Learn on for February bulletins from AddUp, Airbus, Vivid Laser Applied sciences, LandSpace, EOS, DyeMansion, the European Area Company, and extra.

Fundraising efforts and monetary challenges

Following final month’s Arevo 3D printing {hardware} public sale, February noticed extra additive manufacturing belongings put up on the market. After experiencing worsening monetary outcomes since its 2021 $605 milion SPAC deal, Shapeways introduced a spread of cost-cutting actions, together with a 15% workforce discount.

February noticed the corporate public sale $5 million of its Desktop Steel 3D printers, together with P1 Manufacturing Techniques, binder jet Store Techniques, and BMD 3D printers. This was the agency’s second {hardware} public sale, having beforehand listed $4 million value of Desktop Steel 3D printing expertise in October 2023.

This mirrored Shapeways’ worsening monetary place for the reason that SPAC merger. In 2021, the agency initially projected 95% annual development between FY 2021 and FY 2022, adopted by anticipated 2024 revenues of $250 million. Nevertheless, by Q3 2023, Shapeways posted complete income of simply $8.4 million, $3.4 million in gross revenue, and a web lack of -$19.4 million. On 2 February 2024, the corporate’s share value was simply $1.94, down from $83.60 per share on 11 January 2021.

Updates on Shapeways’ monetary place stayed within the headlines all through 2024. Though the outlook appeared gloomy at the beginning of the 12 months, later months would chart a shocking change in fortunes.

One firm with a much less optimistic future was Uniformity Labs. Questions have been raised in regards to the engineering supplies specialist’s survival after $10 million value of its steel 3D printing belongings have been put up on the market in February. This {hardware} included an ALD Vacuum Applied sciences’ Viga 35 Vacuum Fuel Atomizer system priced at $3.5 million, SLM Options’ 280HL Twin 700W laser powder mattress fusion (LPBF) 3D printer, SLM 125M 3D printer, EOS M290 LPBF system, and a Desktop Steel P1 Manufacturing System. Regardless of elevating $38.35 million in Sequence B funding in 2021 and launching a brand new UniFuse IN625 Nickel Alloy at RAPID + TCT 2023, Uniformity Labs ceased buying and selling quickly after the public sale.

Additionally within the information was Desktop Steel. Following final month’s choice to provoke a $50 million price discount, the corporate filed a $250 million mixed-shelf providing. This included most well-liked inventory, debt securities, warrants, items, and as much as $75 million of sophistication A standard inventory.

Shelf choices permit firms to lift capital by issuing new securities with no need to instantly promote them. The securities are saved “on the shelf,” and will be issued when enterprise situations are favorable. Desktop Steel’s class A standard inventory providing had an combination value of $75 million.

Whereas some firms confronted monetary struggles at the beginning of 2024, it wasn’t all doom and gloom. Final month, the 3D Printing Trade Govt Survey highlighted an optimistic outlook for the way forward for 3D printing, with business specialists anticipating a wholesome enterprise atmosphere.

One firm to capitalize on this optimism was CORE Industrial Companions, which efficiently raised $887 million in capital commitments in February. This funding continued CORE’s technique of investing capital in industrial manufacturing. Over the previous 5 years, the corporate has raised over $1.58 billion in restricted associate commitments for this technique. Finally, CORE is working to construct one of many “largest world additive manufacturing firms” by buying 3D printing bureaus and machine retailers.

3D printing Client merchandise

February witnessed a eager deal with 3D printed shopper merchandise. This was pushed by US sports activities gear producer Wilson Sporting Items Co. which commercialized its 3D printed airless basketball. First unveiled as a prototype final 12 months, the Wilson Airless Gen1 hit the cabinets for $2,500 in a restricted launch.

The 3D printed basketball was co-developed by 3D design specialists Normal Lattice, 3D printer producer EOS, and post-processing firm DyeMansion. California-based SNL Artistic was the first manufacturing hub for the launch. Notably, the 3D printed lattice construction options eight panel-like “lobes” which take away the necessity for inflation. Wilson claims the ball is absolutely useful and meets NBA rules for weight, dimension, and bounce.

3D printed bikes additionally made headlines this month. Supplies specialist Lehvoss Group partnered with E-bike producers Buddy Bike and Isoco Bikes to develop the Isoco X1 e-bike. Designed with sustainability in thoughts, this shopper product contains a 100% recyclable thermoplastic body and a 68% smaller carbon footprint than its aluminum counterparts. Thomas Collet, Lehvoss’ Personalized Polymer Supplies Director of Advertising and marketing, instructed 3D Printing Trade that additive manufacturing was used to develop and prototype a number of the ISOCO X1’s elements.

In different information, 3D printing supplies developer Elementum 3D partnered with German machine software producer TRUMPF to improve INTENSE Cycles‘ M1 downhill race bike. INTENSE leveraged TRUMPF’s capabilities to 3D print the bike’s spine as a single piece. Elementum’s A6061-RAM2 aluminum alloy was 3D printed utilizing TRUMPF’s “TruTops Print” construct processor, which diminished overhang assist materials necessities.

3D printing at Crimson Bull Racing

Ian Handscombe, Crimson Bull Racing’s Head of High quality Engineering, defined how the crew makes use of 3D printing in Method One. He emphasised how superior manufacturing offers Crimson Bull the profitable edge, stating “I don’t assume we’ll proceed to be on monitor until we embrace [3D printing].” Handscombe, who has three many years of expertise within the automotive business, referred to as additive manufacturing the “quickest rising expertise” inside F1.

In the course of the dialogue, Handscombe highlighted the significance of technical partnerships, significantly with firms like Hexagon. By means of these collaborations, Crimson Bull has built-in superior applied sciences into their operations, pushing efficiency limits whereas making certain race-car security and reliability.

In accordance with Handscombe, Hexagon performs a vital position in figuring out and delivering vital gear, whereas helping in improvement and coaching. “Hexagon has been with us each step of the way in which,” added Handscombe.

He added that the crew leverages additive manufacturing “an terrible lot.” It’s evaluating scale its use from 3D printed fashions for wind tunnel testing to having “increasingly more” 3D printed parts on the race automobile. The automotive skilled believes “3D printing will begin to change mechanical elements on the automobile quickly.”

Additive manufacturing helps house flight

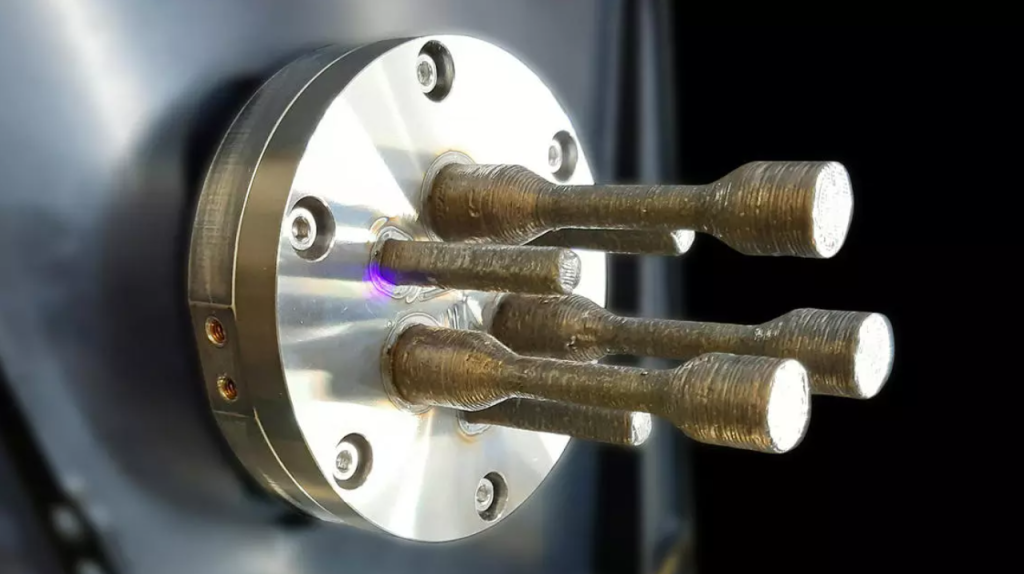

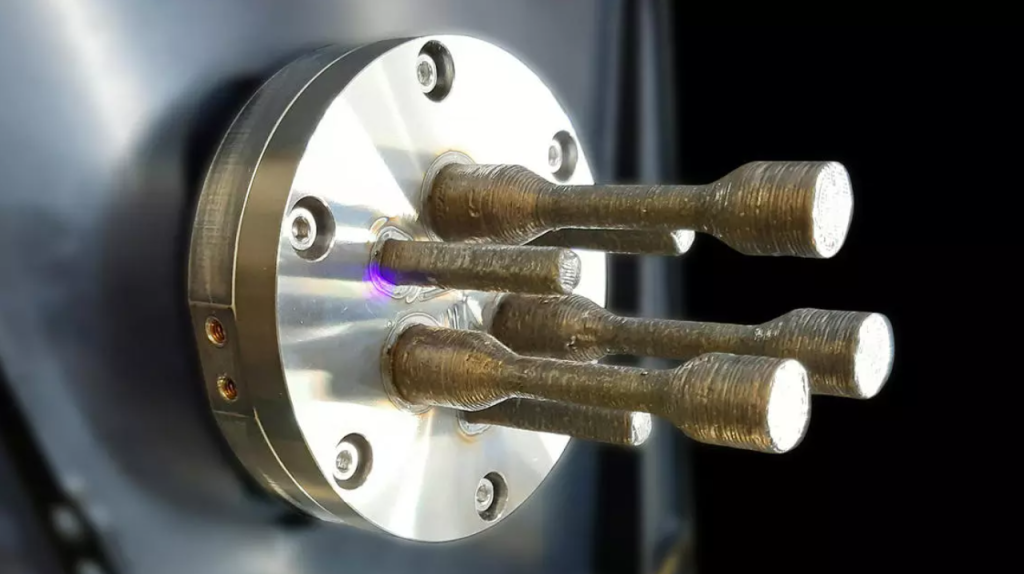

February’s 3D printing information witnessed important bulletins inside the house sector. A European Area Company (ESA) contract noticed AddUp and Airbus Defence & Area collaborate to develop a system to allow 3D printing in house.

The businesses developed two programs to guage additive manufacturing capabilities and efficiency in microgravity situations. The “flight mannequin” 3D printer was launched to the Worldwide Area Station by means of the ESA’s “Metal3D” undertaking. It underwent testing on the Area Station’s Columbus module, with operational 3D printing starting by early March.

In the meantime, an “engineering mannequin” remained on Earth. Astronauts will 3D print 4 samples in house, which might be returned to Earth and analyzed alongside the terrestrial 3D printed elements. Mechanical power, bending assessments, and microstructural evaluation might be performed to guage the results of microgravity on 3D printing.

In different house information, Non-public Chinese language firm LandSpace accomplished the primary profitable take a look at launch of its reusable Zhuque-3 VTVL-1 3D printed rocket. This “hop” take a look at mission validated the vertical takeoff and touchdown (VTVL) Liquid Oxygen-Methane rocket’s first stage. It reached an altitude of round 350 meters in 60 seconds, earlier than setting down on a delegated touchdown space.

Vivid Laser Applied sciences’ steel 3D printing capabilities performed a key position in producing the rocket. The Zhuque-3 featured a slew of 3D printed parts, together with joint components, igniter mounts, and its intricate free-body part. The latter required a fancy inner cooling construction.

Vivid Laser Applied sciences acknowledged that standard manufacturing processes failed to satisfy the standard necessities of the free-body part. The corporate’s BLT-S310 and BLT-S400 Steel 3D printers efficiently addressed these calls for. LandSpace added that additive manufacturing expedited deliveries, diminished manufacturing time, and unlocked fast improvement iterations.

Researchers obtain 3D printing breakthroughs

Educational analysis tasks continued to push the boundaries of additive manufacturing in February. One crew from the College of Illinois Urbana-Champaign and the Beckman Institute for Superior Science and Know-how developed a brand new technique for multi-color 3D printing.

Typical multi-color 3D printing approaches require the usage of a number of supplies. Nevertheless, the researcher’s novel course of solely requires a single ink, enhancing sustainability and effectivity. They drew inspiration from color-changing chameleons to create a UV-assisted-ink-writing strategy that permits structural colours to be modified “on the fly” throughout 3D printing.

By altering the power of UV mild, the researchers efficiently achieved a variety of colours. This was demonstrated by means of 3D printed artwork items, together with a chameleon picture and a recreation of Vincent Van Gogh’s “Starry Evening” portray. Each showcased the broad spectrum of yellows, greens, and blues attainable with a single ink.

Elsewhere, researchers from the College of Wisconsin-Madison developed a brand new strategy for 3D printing human mind tissue. The novel course of can create lively neural networks in and between tissues.

Present strategies usually create an uneven distribution of neural cells. The brand new strategy overcomes this by 3D printing the mind tissue horizontally. Thrombin was added as a crosslinking agent after the tissue was deposited to forestall the 3D printed cell bands from mixing.

The crew believes the 3D printed mind tissue can function a precious software for modeling mind exercise below physiological and pathological situations. The tissue was additionally touted as an efficient drug-testing platform.

3D Printing Information Highlights from 2024: Improvements, Tendencies, and Evaluation

All of the information from Formnext 2024.

Subscribe to the 3D Printing Trade e-newsletter to maintain up with the newest 3D printing information.

You can too comply with us on Twitter, like our Fb web page, and subscribe to the 3D Printing Trade Youtube channel to entry extra unique content material.

Featured picture exhibits 3D printed Wilson Airless Gen1 basketballs. Picture by way of Wilson.