Have you ever ever dreamt of getting a companion like Cal Kestis, a former Padawan who tried to rebuild the fallen Jedi Order in Star Wars? BD-1 may also be your good friend, serving to you re-embrace your imaginary Jedi function within the battle towards the Empire. All you want is a 3D printer, BD-1 3D mannequin STL information for 3D printing, some portray abilities, and a bit of persistence and keenness on your interest.

Fanatic Kyra Schefter has completed her BD-1 droid and is joyful to share her steps of respiratory life into this large-scale 3D print. Her concepts and suggestions may be your private masterclass on learn how to reanimate Jedi Fallen Order droid and produce him from the display into your actual life.

BD-1 Droid

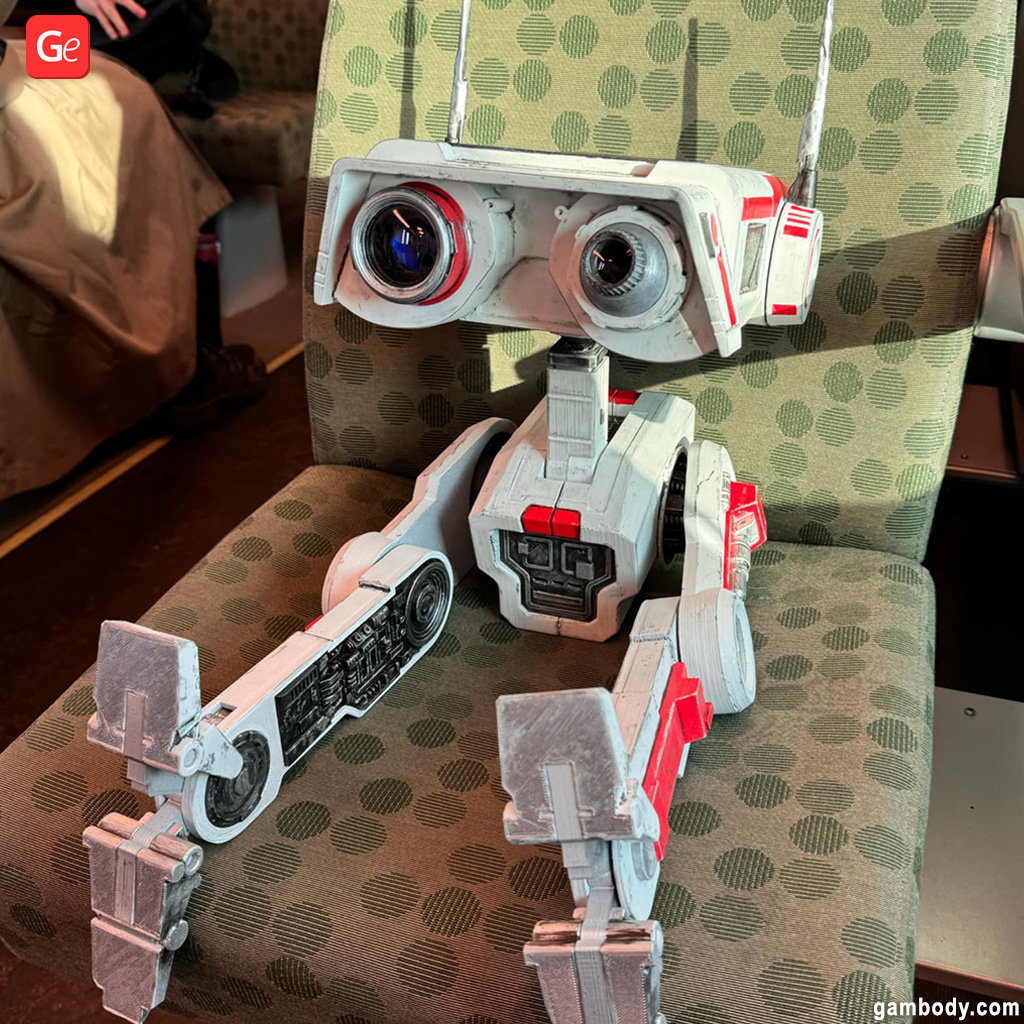

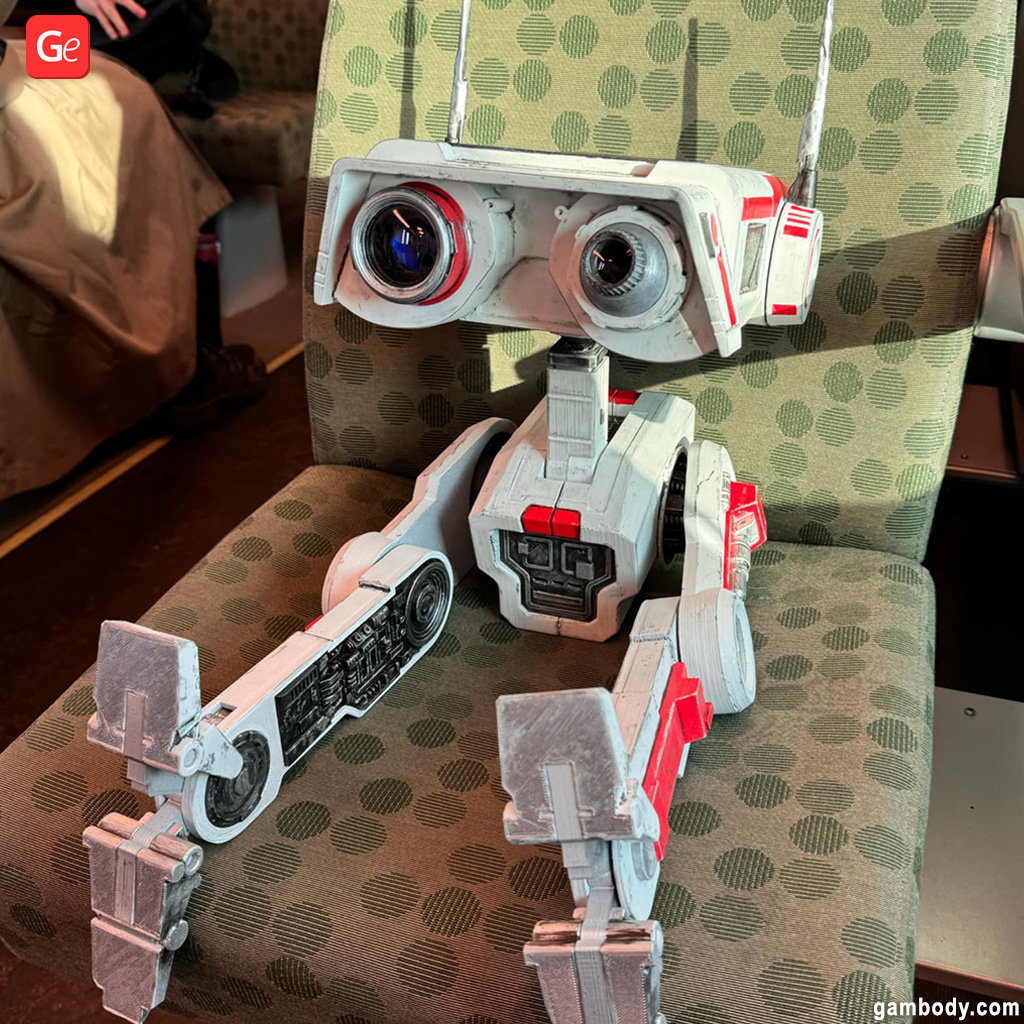

You might be welcome to undertake BD-1 droid 3D printing information on gambody.com. This lovely and extremely detailed undertaking will allure you in seconds. The mannequin boasts articulated head/hip/knee/ft joints, a rotating holoprojector, a detachable aspect panel that allows you to take a look at the inner elements, a neck you possibly can bend and lengthen, a detachable panel in the back of the pinnacle, and rather more!

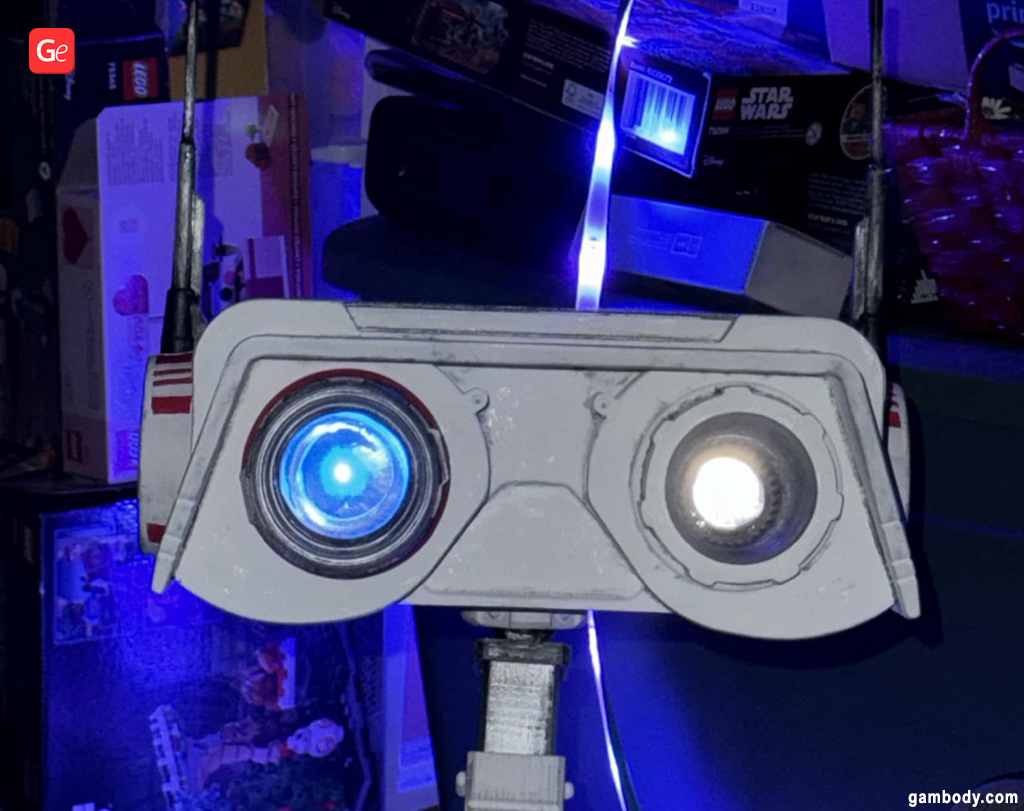

This implausible Cal Kestis droid has tunnels for LED wiring in an effort to add lights to its holoprojector, head, and sensor. You’ll be able to disguise a battery contained in the BD-1’s head behind the detachable panel. All these options and specs make this 3D printing mannequin a must have in your assortment!

Star Wars BD-1 3D Print

Kyra Schefter’s BD-1 seems clever, extremely detailed, and tremendous cute. The hobbyist used the FDM model of this 3D printing mannequin, which turned her first-ever larger-scale undertaking and become two months of enjoyable in making it.

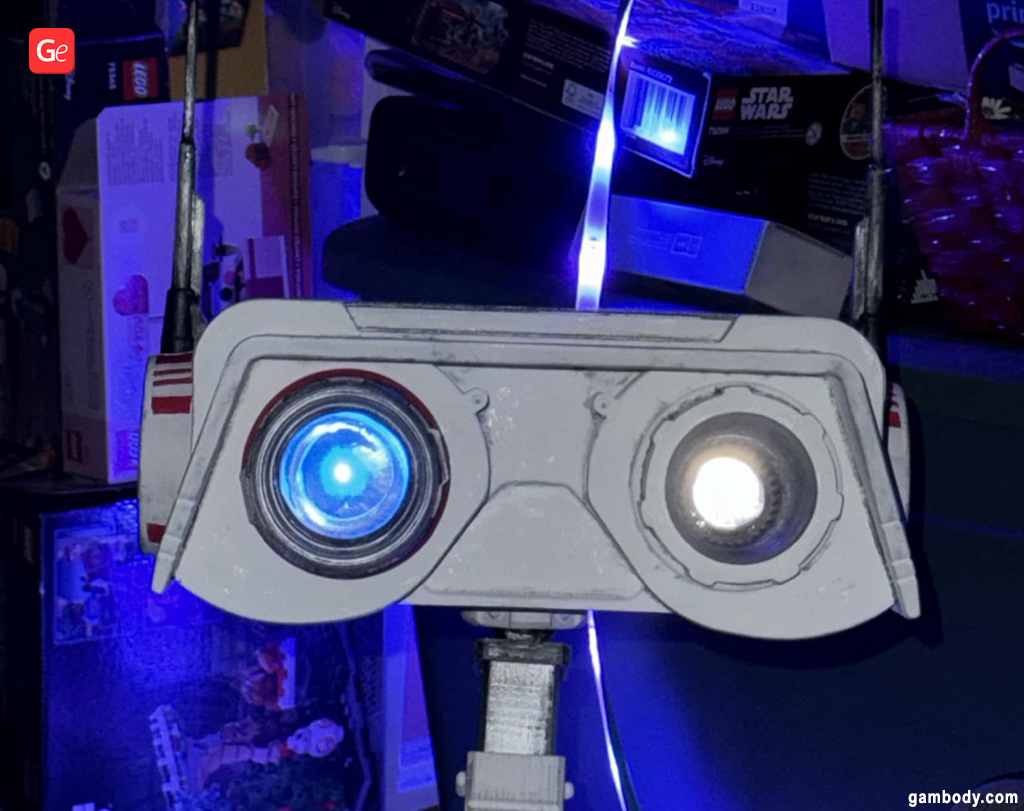

Taking part in over 120 sounds, having real eye lenses and eyes with particular person switches to activate/off independently, this BD-1 takes a particular place in Schefter’s coronary heart. So, how did she create this droid?

3D Printing & Meeting

The hobbyist 3D printed BD-1 utilizing 3 kg (6.6 lbs) of PLA filament, Creality Ender-3 3D printer, Gambody’s premium STL information of the droid, and the Cura slicer. Following directions that include 3D printing information and a video, Kyra constructed the droid at 100% and one-half of its antenna ratchets at 98% (as advisable by Gambody help staff) to make the ratchets transfer extra easily.

She says all of the elements really feel very sturdy, and all the pieces matches collectively just about completely. After taking part in with the ratchets, she used some dremeling and sanding to make the ratchet halves much less stiff, which was a very simple repair.

When assembled, the droid amazes with the durability of all its elements. Each joint holds nice though the pinnacle, physique, and different components are fairly heavy. Nonetheless, the ball joints work splendidly, and you may screw them the best way to pick how tight or unfastened to remain.

When you can assemble the robotic with out glue as a result of joints join the elements vastly, Kyra recommends you glue the pinnacle components together with the antenna ratchets and legs to the ball joint pin to remain protected.

Portray

Every 3D printed piece was sanded and primed with grey Rust-Oleum automotive primer spray. The maker used waterproof Rust-Oleum spray paints of various colours, together with black, white, poppy purple, silver, and sparkly darkish grey.

Learn additionally: Sanding and Portray 3D Prints: Straightforward Steps.

It was the primary time Kura spray painted and weathered a mannequin. She used paper towels and a sponge to climate greater silver elements (she added silver paint to the droid edges after sanding them to fake the paint had scraped off the robotic). For smaller elements, comparable to antennae and crevices (they have been painted with darkish grey colour to fake it was grime), she used a paintbrush for touch-ups.

Droid Articulation

The maker loves the droid’s articulation. In accordance with Schefter, BD-1 can maintain any place you make. Whereas the actions usually are not as actual as they seem within the video games, this is because of 3D printing materials (plastic).

Fixing 3D Print

Had been there any points whereas engaged on this spectacular Star Wars mannequin? Errors and errors can occur if you 3D print, regardless of how detailed and error-free STL information are. Whereas engaged on the Jedi Fallen Order droid, the hobbyist needed to reprint some components, discover a technique to make clear eye lenses, repair the damaged antennae, and reinforce the joints.

Discovering the right eye lens was a trial. The fanatic tried to 3D print the lens utilizing included STL information and translucent filament, which seemed white and never black with lights off. Utilizing black clear filament didn’t repair this example as a result of it hardly allowed any mild by. The Mod Podge Dimensional Magic epoxy-like components utilized to packaging plastic wasn’t too clear, however watch glass replacements labored like magic!

The robotic’s antennae broke just a few occasions (when the 3D printed head fell off the desk), so Kyra used wire and electrical tape to bolster these elements earlier than repainting them silver. Such a repair was so nice that the antennae survived when any individual stepped on them at Comedian-Con!

P.S. If the undertaking’s leg ball joints break on you, you possibly can repair it by rising the infill when 3D printing it once more.

Wiring

Kyra needed the droid’s eyes to be lit, so she added the essential LED wiring, blue for one eye and white for the opposite one. They work independently of one another, so you possibly can flip them on and off individually.

To make eyes really stand out, the hobbyist used the domed watch glass replacements from Amazon, which labored completely properly. The smaller one, 20 mm watch glass, has match into the BD-1 eye with almost no adjusting. The larger one, 40 mm watch glass, required loads of sanding right down to 38-39 mm earlier than it match correctly as a substitute.

The backlight panel is 3D printed utilizing clear filament, painted black in a grid-like sample.

Learn additionally: Easy methods to Put Up LED Lights in a 3D Printed Mannequin.

General, the mannequin has lights and sounds taking part in by him (the financial institution contains over 100 distinctive sounds). Painted, wired, and assembled, the 3D printed BD-1 droid weighs roughly 4.5 lbs (2 kg).

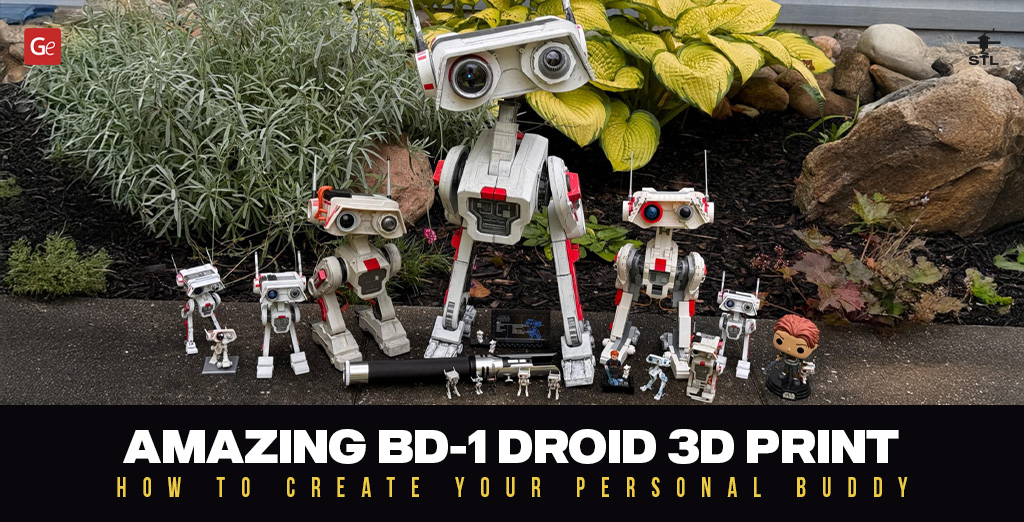

As talked about above, it took Kyra roughly two months to make the BD-1 droid, from starting to 3D print it to ending and sharing this information with our readers, and he or she nonetheless provides small changes and fixes. The mannequin is so spectacular that you just may wish to have one in all your personal and share your photographs on FB Gambody 3D Printing Group. By the best way, Schefter’s assortment may at some point get a smaller model of BD-1, printed at about 50%. What a implausible concept for a Star Wars fan, isn’t it?

(Visited 140 occasions, 1 visits as we speak)