Bettering Injection Molding Effectivity with Conformal Cooling

Based in 2007, Japanese Rail Company constructed a fame on designing sustainable, high-quality options for the Metro Rail infrastructure within the US. For a selected part—an insulator that isolates the electrified third rail in underground subway methods–Japanese Rail wanted to replace the fabric to satisfy security requirements. A swap to Polyphenylene Sulfide (PPS) subsequently required a reevaluation of the prevailing mildew. To deal with this subject, Japanese Rail approached Linear AMS, a Shapeways Firm, in search of partnership in creating an modern resolution to reinforce performance and effectivity.

Japanese Rail is a long-standing buyer, supporting transit companies in metropolitan areas like New York Metropolis, Washington, D.C., and Miami, the place city rail methods steadily function in underground tunnels. Such an setting calls for elements with particular dielectric properties, safeguarding in opposition to undesirable electrical expenses and permitting for simpler administration of underground practice traces.

Incorporating Superior Cooling Know-how

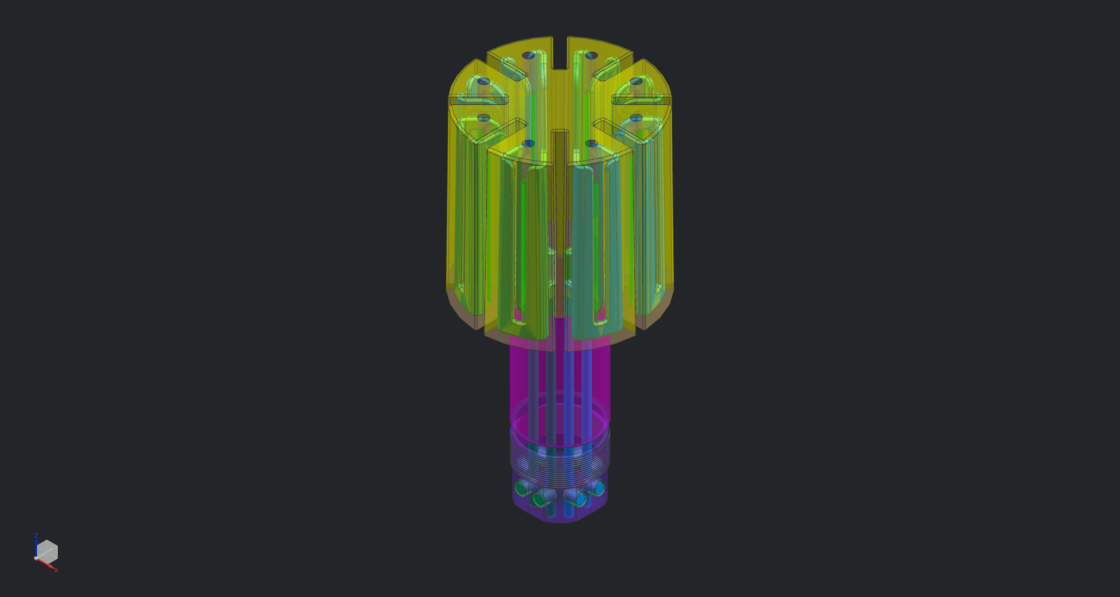

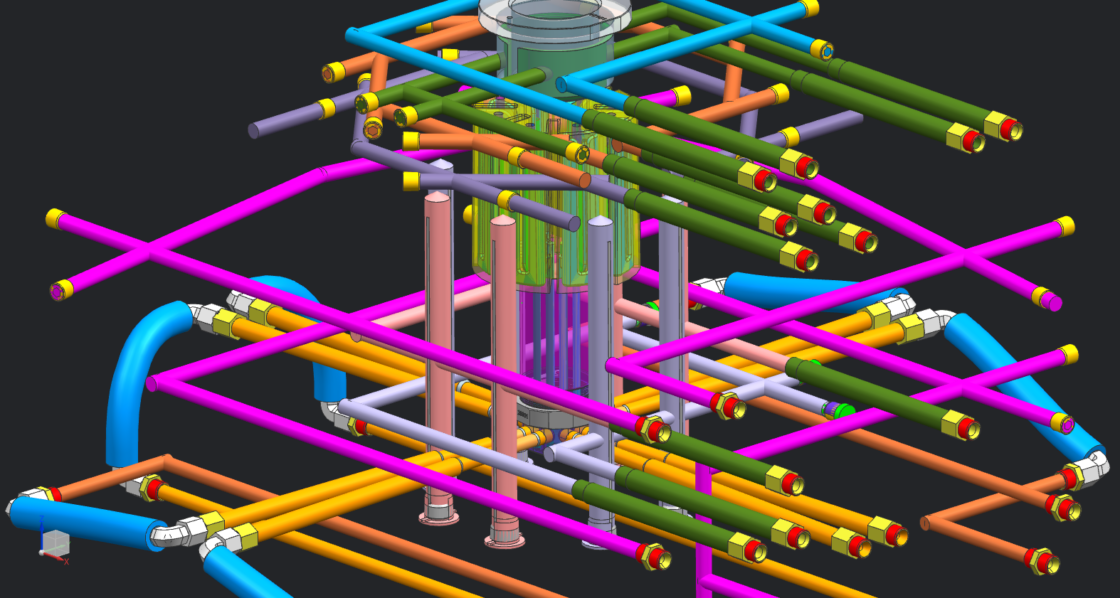

Injection molding producers usually face challenges associated to lengthy cycle instances, half high quality, and total effectivity. Conformal cooling expertise particularly resolves these issues. Counting on 3D printing for personalisation and effectivity, conformal cooling adapts to suit into industrial molds.

In distinction to standard strategies, that are restricted to machining in straight traces, conformal traces are designed to comply with the form of the half itself–resulting in a extra constant temperature all through the half’s cooling stage. Which means that elements are much less more likely to warp, whereas additionally cooling as much as 50% quicker. With conformal cooling, producers can scale back their cycle time and enhance their throughput, all whereas bettering half high quality.

For Japanese Rail, integrating this expertise produced extra constant temperatures in tooling, resulting in extra environment friendly manufacturing cycles, satisfying stringent necessities for dependable and environment friendly rail methods.

Bettering Tooling for Complicated Supplies

Initially, Japanese Rail encountered challenges because of the advanced half design and core mildew options, mixed with the character of Xencor™ PPS LGF-3045, a forty five% long-glass, fiber-reinforced Polyphenylene Sulfide (PPS).

Whereas offering helpful properties like warmth resistance and sturdiness, PPS additionally presents manufacturing difficulties. Linear carried out a complete evaluation, revealing that Japanese Rail’s present tooling with typical cooling–together with a PPS materials–wouldn’t produce a moldable half.

“I used to be conscious a brand new strategy can be essential with the change in materials,” stated Mickey Morales, CEO of Japanese Rail. “After working with Linear for the previous decade, I used to be assured of their engineering experience and knew they had been able to delivering the dynamic resolution this mission wanted.”

To handle these points, Linear and Japanese Rail labored side-by-side for months in prototyping and testing, experimenting with molds and the mixing of 3D printed conformal cooling traces.

Upon preliminary evaluate, the workforce urged making the change to a metal mildew over aluminum for manufacturing volumes. The PPS materials is extremely corrosive and would deteriorate the aluminum mildew. Transitioning to a metal mildew additionally opened up the potential for utilizing conformal cooling to permit for higher thermal management. Moreover, primarily based on the molding temperature necessities of PPS, the workforce decided scorching oil can be essential to take care of instrument temperature, versus water which is extra generally used.

“The shift to metal molds considerably remodeled our strategy, working significantly better with the distinctive traits of PPS and the necessity for a exact, managed molding setting,” stated John Tenbusch, Director of Automotive Gross sales at Shapeways.

“After working with Linear [A Shapeways Company] for the previous decade, I used to be assured of their engineering experience and knew they had been able to delivering the dynamic resolution this mission wanted.”

Mickey Morales, CEO of Japanese Rail

Decreasing Cycle Occasions & Bettering Half High quality

The introduction of conformal cooling was extremely efficient, yielding a outstanding enchancment in effectivity after Linear launched metal tooling. Implementing conformal cooling led to a design adjustment that considerably lower prices. Interchangeable inserts, normally requiring three cores, had been lowered to only one.

“We needed to incorporate cooling a technique or one other,” stated David Dickerson, Supervisor of Shopper Providers at Shapeways. “With out conformal cooling, we couldn’t have made the interchangeable elements we wanted for the varied sizes of the insulator.”

With the brand new metal molds and conformal cooling inserts, the Linear workforce was capable of scale back the cycle time from 181 seconds to 138 seconds, reflecting a 23% enchancment. Diminished manufacturing time permits for extra elements to be made, decreasing each piece price and total program price, with out sacrificing half high quality. The extra even, managed temperatures additionally led to the manufacturing of higher-quality, extra dependable elements.

Whereas the preliminary prototyping and testing part required important time and monetary funding, the associated fee financial savings over the long run greater than justified the upfront expenditure. The improved materials sturdiness, decrease upkeep wants, and elevated manufacturing speeds collectively contributed to important long-term financial benefit for Japanese Rail.

“Whereas we encountered a number of obstacles throughout our journey, Linear’s workforce of consultants was once more capable of present a extremely engineered resolution whereas offering cost-saving advantages,” stated Mickey Morales, CEO of Japanese Rail.

Aligning with Regulatory and Environmental Issues

Japanese Rail’s openness to new options enabled enhancements with each brief and long-term advantages, assembly industry-specific wants whereas sustaining a dedication to environmentally pleasant supplies and regulatory compliance.

This case research presents helpful problem-solving insights for points associated to supplies, tooling, and cooling. These options could also be relevant to different manufacturing sectors as nicely. General, this mission showcases the worth of teamwork, innovation, and excellence in manufacturing

Discover out extra about how Shapeways can collaborate along with your firm.