Researchers from the College of Groningen have developed a low-cost, scalable methodology for detecting faults in wind turbine blades utilizing 3D printed fashions, vibration evaluation, and machine studying. The research demonstrates how scaled replicas of the NREL 5MW blade, fabricated with PLA, can be utilized to simulate injury situations and precisely classify structural faults utilizing assist vector machines and k-nearest neighbors with over 94% accuracy.

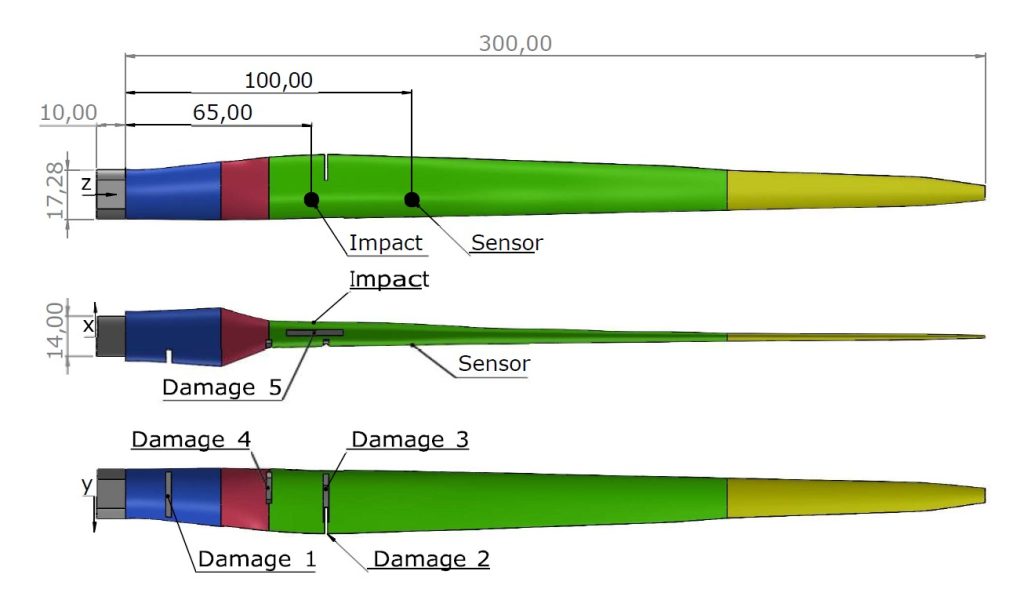

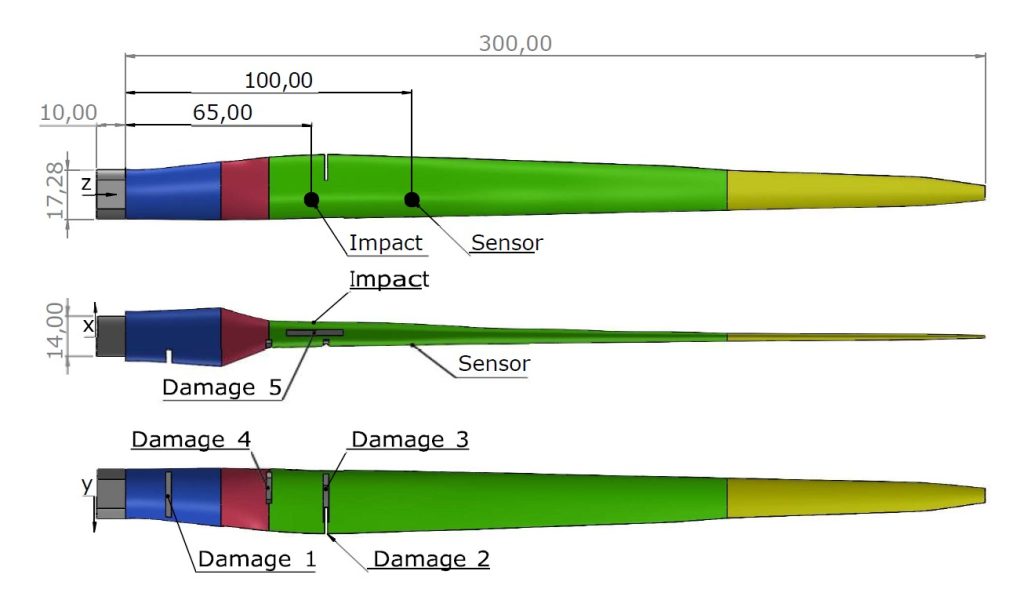

Wind turbine blades endure steady mechanical stress and harsh environmental circumstances, making early injury detection essential to make sure structural integrity and scale back upkeep prices. Conventional inspection strategies are sometimes pricey and labor-intensive. On this research, the researchers used a Bambu Lab 3D printer to manufacture a 300 mm scaled model of the NREL 5MW blade, introducing 5 sorts of crack-like damages in essential areas equivalent to the foundation, mid-span, and transition zones.

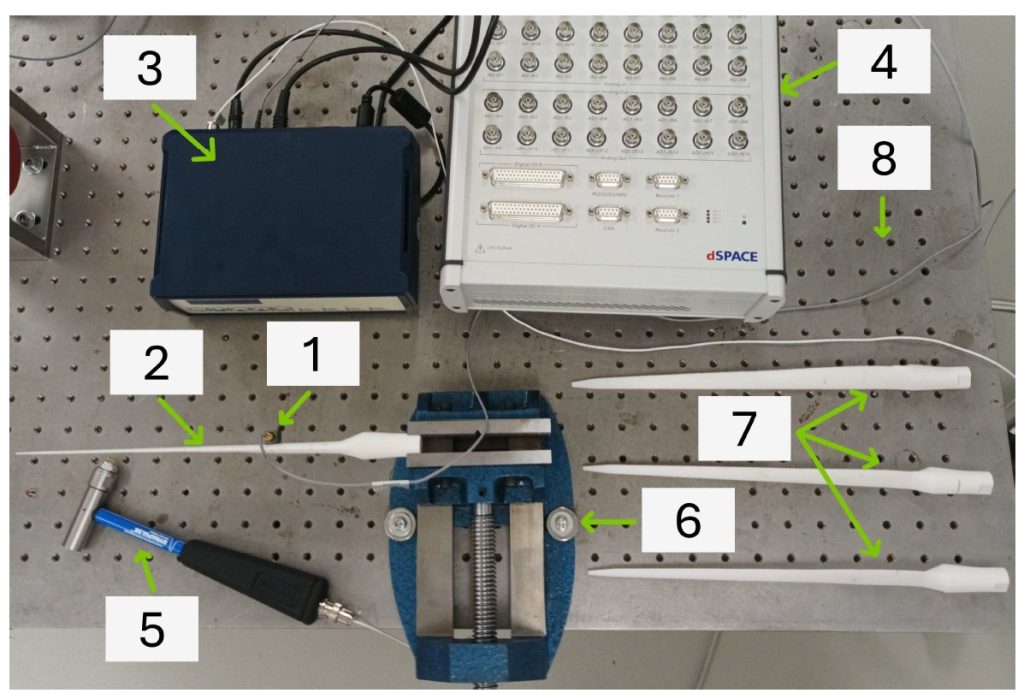

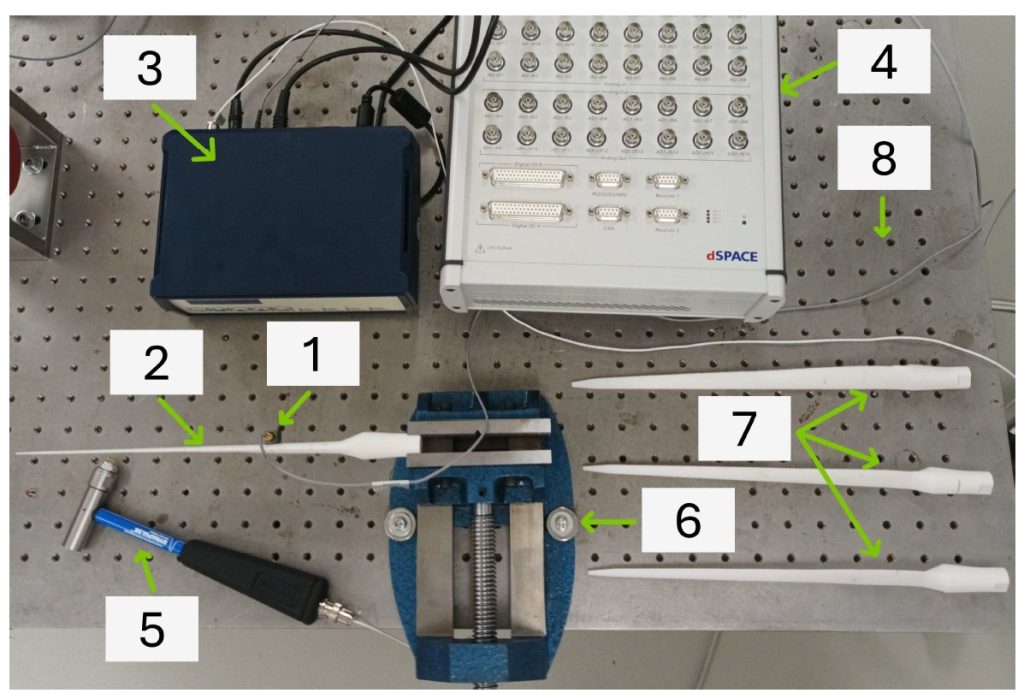

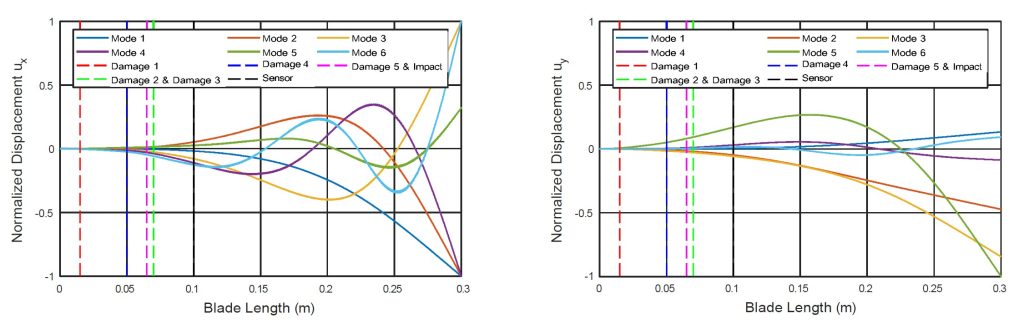

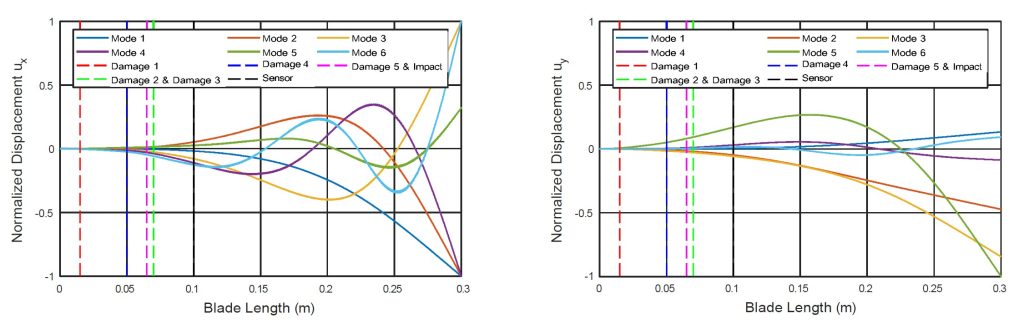

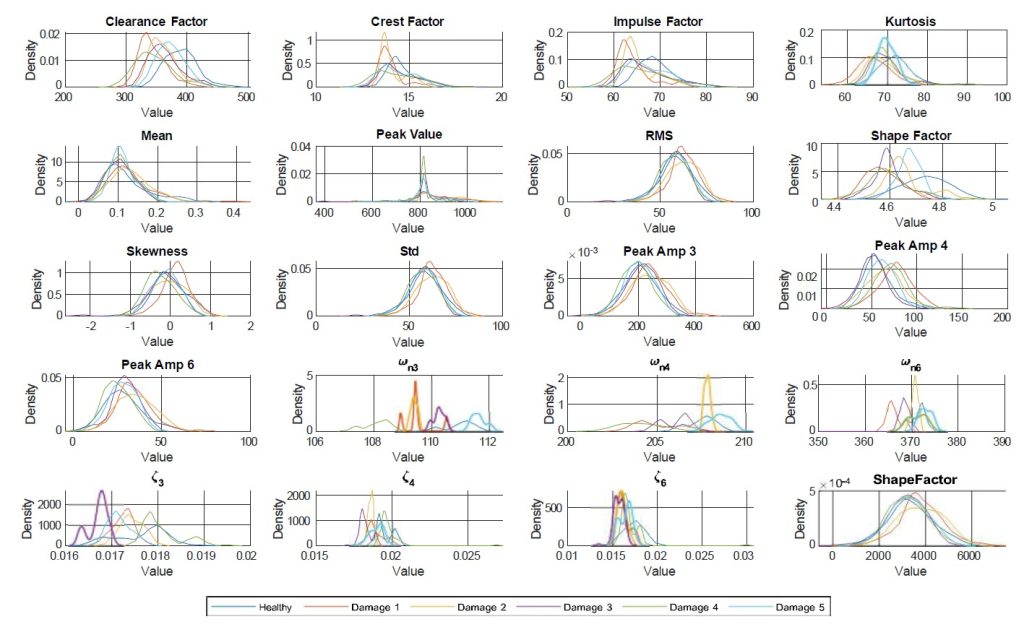

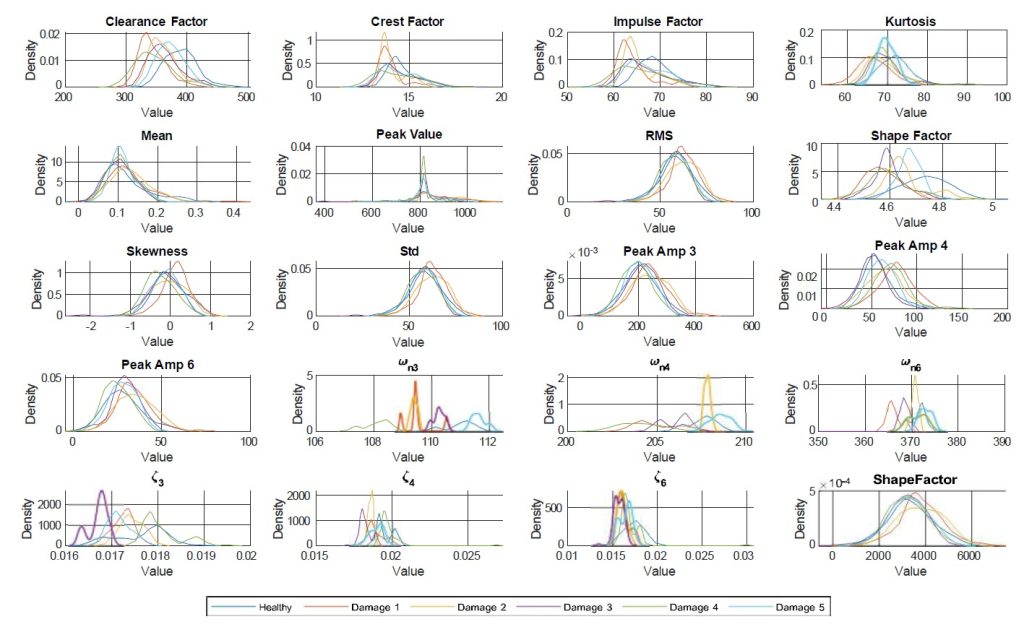

To guage the structural influence of the faults, the crew performed Finite Factor Technique (FEM) simulations and validated the outcomes by experimental modal evaluation utilizing a hammer check setup. The resonance frequencies for vibration modes 3, 4, and 6 have been discovered to be notably delicate to structural anomalies. Frequency shifts of as much as 3 Hz have been noticed in these modes when in comparison with wholesome blades.

Characteristic extraction and machine studying

The researchers extracted options from the time and frequency domains, deciding on these with the best statistical significance by ANOVA testing. These options have been then used to coach a number of machine studying fashions, together with Random Forest, Help Vector Machine, Ok-Nearest Neighbors, and Naive Bayes classifiers. Amongst them, KNN and SVM achieved the best classification accuracy, exceeding 94%.

By combining 3D printing, simulation, and machine studying, the research gives a reproducible and cost-effective methodology for structural well being monitoring of wind turbine blades. The crew plans to broaden the methodology to multi-blade methods and extra advanced fault configurations, aiming to combine it into real-time monitoring methods for predictive upkeep.

3D printing in wind vitality analysis

This research aligns with current developments in wind vitality analysis, together with NREL’s MADE3D mission, which explores how additive manufacturing can improve the structural and aerodynamic efficiency of turbine blades.

Moreover, 3D printing is more and more getting used to lengthen the lifecycle of wind turbine parts. In a single current case, a decommissioned wind turbine blade was repurposed right into a modular footbridge utilizing additive manufacturing. The mission showcased how reused blade materials and 3D printed connectors can type sustainable civil infrastructure, additional highlighting the intersection of wind vitality and digital fabrication.

As additive applied sciences acquire traction for large-format wind parts, analysis into digital instruments for fault detection and design optimization is changing into more and more related to the renewable vitality sector

What 3D printing tendencies do you have to be careful for in 2025?

How is the way forward for 3D printing shaping up?

To remain updated with the newest 3D printing information, don’t neglect to subscribe to the 3D Printing Business e-newsletter or comply with us on Twitter, or like our web page on Fb.

Whilst you’re right here, why not subscribe to our Youtube channel? That includes dialogue, debriefs, video shorts, and webinar replays.

Featured picture reveals blade geometry of the scaled NREL 5MW blade. Picture by way of College of Groningen.