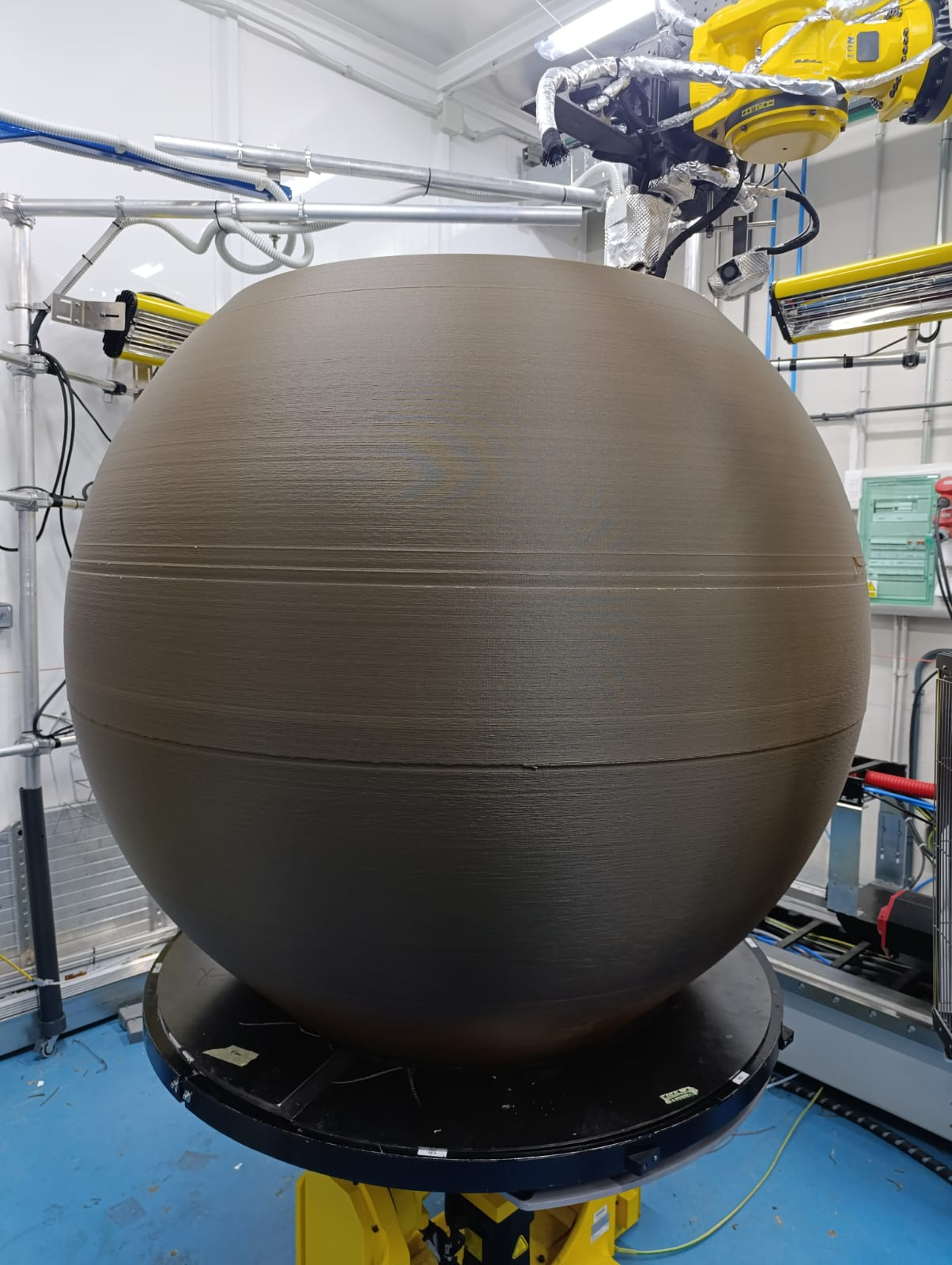

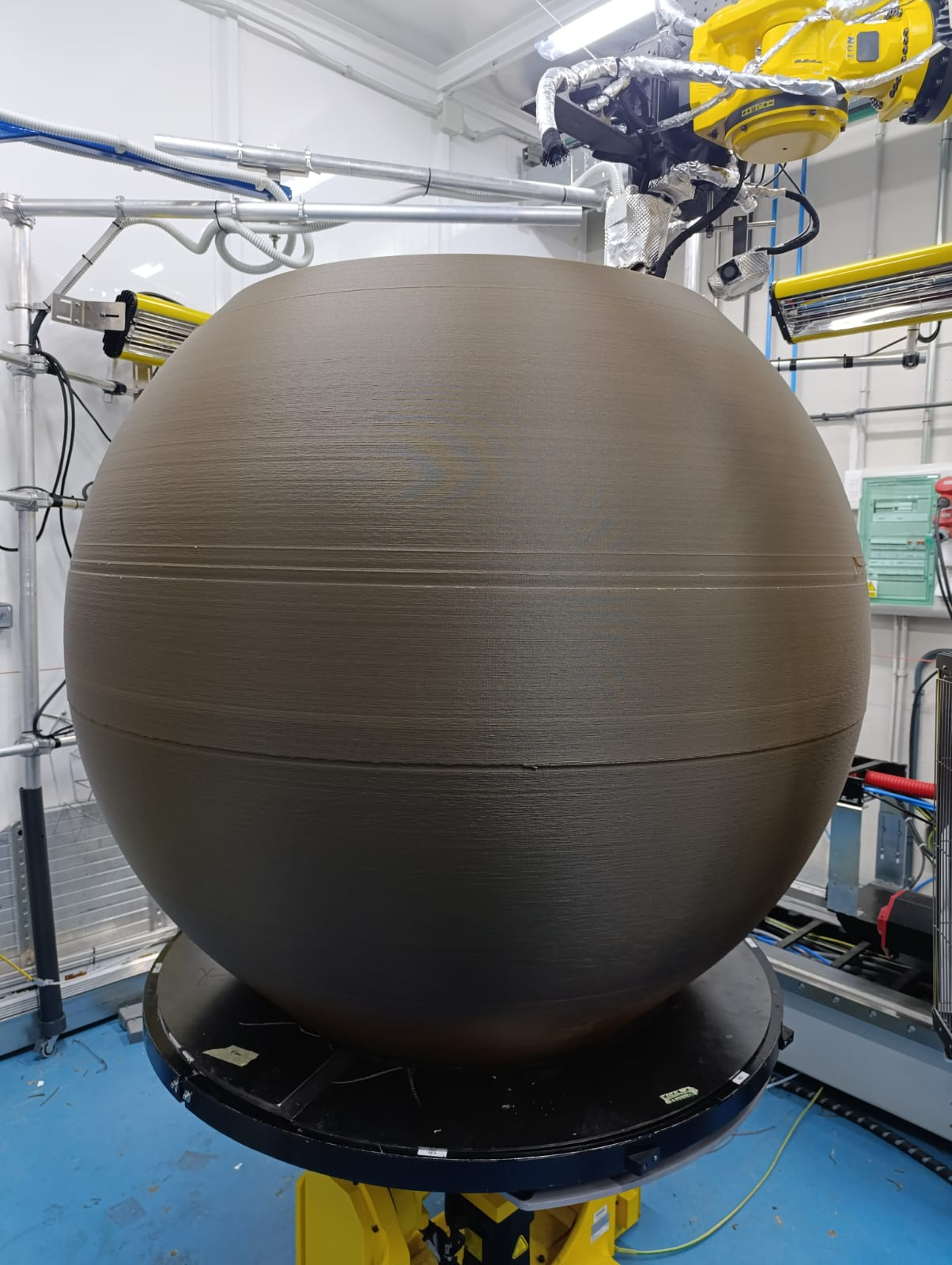

Aimen Expertise Centre has accomplished the 3D printing of a cryogenic tank demonstrator for the OVERLEAF challenge. The Spanish group manufactured a 1.5-meter-diameter inside tank designed to retailer liquid hydrogen (LH2) at extraordinarily low temperatures for future plane functions. The challenge is led by Aciturri, a Spanish aeronautics firm engaged on hydrogen storage options.

The tank design incorporates a dual-component system combining an additively manufactured thermoplastic inside vessel with an outer carbon fiber construction. The inside element maintains the liquid hydrogen at cryogenic temperatures, whereas the carbon fiber exterior offers structural integrity. Aimen utilized large-format additive manufacturing with excessive precision to create the inside tank.

“This can be a technological answer that can mark a earlier than and after within the manufacturing of parts for sustainable aviation,” stated Pablo Romero, staff chief of the Additive Manufacturing of Composites R&D group at Aimen. The manufacturing course of required over 100 hours of steady printing in a specialised robotic cell developed by Aimen. Actual-time monitoring with thermal cameras ensured high quality management all through the prolonged construct.

The manufacturing cell included high-performance 3D printing methods alongside infrared heating know-how to make sure correct adhesion between layers. This technical strategy was crucial to fulfill the demanding necessities for hydrogen storage methods in aviation functions. The tank represents a major step towards enabling hydrogen as an aviation gas supply.

Aimen collaborated with French analysis middle Canoe to develop a brand new sustainable materials for the challenge. The bio-based thermoplastic bolstered with pure fibers permits for printing sturdy, light-weight buildings with diminished environmental impression. This materials improvement aligns with the broader targets of making extra sustainable aviation applied sciences.

Supply: compositesworld.com