3D printing information from October 2024 encompassed large-scale additive manufacturing in aerospace, groundbreaking developments in sustainable applied sciences, important strides in medical bioprinting, strategic company mergers, and ongoing debates in protection and coverage. The business continued to showcase its modern potential and the complexities that accompany speedy technological developments. Right here, we element the important thing occasions that formed the 3D printing panorama.

Aerospace and Superior Manufacturing

In October, Rocket Lab made one of many month’s most placing bulletins by deploying a 90-ton 3D printer—an automatic fiber placement (AFP) machine from U.S.-based Electroimpact—to assemble what it described because the “world’s largest” carbon composite rocket buildings. At 39 ft (12 meters) tall, this technique can lay down 328 ft (100 meters) of steady carbon fiber per minute. The AFP machine accelerated the manufacturing of the Neutron launch car’s main composite buildings, together with its 91-foot interstage and fairing, decreasing a stage 2 dome’s construct time from a number of weeks to a single day.

As Sir Peter Beck, founder and CEO of Rocket Lab, emphasised that this innovation was central to assembly the calls for of Neutron’s inaugural launch scheduled for subsequent yr. Away from the Neutron rocket, the AFP system is already getting used for panels, tanks, and assemblies in Rocket Lab’s Electron launch car,

Client and Automotive Purposes

Researchers from the Massachusetts Institute of Know-how (MIT) and Delft College of Know-how unveiled a groundbreaking 3D printing course of often called Pace-Modulated Ironing (SMI). This single-material, dual-nozzle FDM method demonstrated as much as ten occasions much less materials waste in comparison with present multi-material techniques just like the Bambu Lab X1-Carbon. The SMI methodology permits any multi-nozzle 3D printer to supply a number of shades, textures, and shapes inside a single print job with out the necessity for filament purging or spool switching.

By depositing a thermo-responsive filament at a low temperature with the primary nozzle and utilizing the second nozzle to “iron” the fabric at various speeds, the workforce might modulate warmth switch to attain intricate patterns and tactile variations. Mustafa Doğa Doğan, a co-author of the examine, highlighted the method’s potential to diversify the traits of 3D printed objects utilizing a restricted set of supplies. Introduced on the Affiliation for Computing Equipment’s Symposium on Consumer Interface Software program and Know-how, this innovation guarantees to reinforce each the aesthetic and practical versatility of 3D-printed merchandise, paving the best way for extra sustainable and environment friendly manufacturing practices.

Within the automotive sector, Jaguar Land Rover (JLR) continued to combine additive manufacturing into its manufacturing processes. Throughout the newest Additive Manufacturing UK (AMUK) Members Discussion board, Luke Fox, JLR’s Additive Manufacturing Technical Specialist, detailed the corporate’s use of 20 industrial 3D printers at its Gaydon-based Additive Manufacturing Centre (AMC). These printers, primarily using polymer powder mattress fusion expertise, allow JLR to supply practical prototypes and bespoke parts effectively.

Trying forward, JLR plans to broaden its steel 3D printing capabilities, exploring applied sciences like binder jetting and steel injection molding (MIM) to assist higher-volume manufacturing functions. This strategic focus aligns with JLR’s dedication to reaching net-zero emissions throughout its provide chain by 2039, using additive manufacturing to attenuate waste and improve manufacturing effectivity.

Environmental Improvements and Medical Developments

October additionally witnessed important developments in environmental sustainability by way of additive manufacturing. Researchers on the College of Tub developed 3D printed ceramic-infused lattice buildings able to eradicating as much as 75% of perfluorooctanoic acid (PFOA)—a persistent “endlessly chemical”—from water in beneath three hours. Fabricated utilizing a VormVrij Lutum 5 extrusion-based clay 3D printer with an indium oxide-infused ink, these ceramic monoliths function a cylindrical scaffold design that maximizes floor space for enhanced chemical absorption.

Dr. Liana Zoumpouli, a analysis affiliate at Tub’s Division of Chemical Engineering, emphasised the tactic’s effectivity: “We are able to take away these chemical substances from water with out utilizing a number of power.” The power to regenerate the monoliths by way of thermal pyrolysis extends their lifecycle, reaching increased absorption charges over a number of cycles. This innovation provides a scalable and energy-efficient answer for water therapy amenities grappling with PFAS contamination, aligning with world efforts to make sure protected and clear water provides.

Within the medical subject, Frontier Bio introduced important progress in creating lab-grown lung tissue by way of bioprinting. By integrating additive manufacturing with the pure self-organizing properties of stem cells, Frontier Bio has created practical lung buildings that replicate key parts similar to bronchioles and alveolar sacs. These bioprinted tissues show important lung features, together with mucus manufacturing and beating cilia, offering a extra correct mannequin for finding out respiratory illnesses like COPD, pulmonary fibrosis, and COVID-19.

Victoria-Elisabeth Gruber, Head of Translational Analysis at Frontier Bio, acknowledged, “There may be an pressing want for extra correct fashions of lung tissue that permit us to check new therapeutics extra successfully than with present strategies.” This growth not solely guarantees to reinforce drug testing and scale back reliance on animal fashions but in addition holds potential for future organ transplantation functions, addressing essential wants in sufferers with continual respiratory illnesses.

Coverage and Protection Developments

The controversy over 3D printed firearms intensified in October, pushed by Chicago’s lawsuit in opposition to Glock and the institution of former President Biden’s Rising Firearms Threats Activity Drive. The lawsuit accused Glock of making the most of the sale of handguns that could possibly be simply transformed into totally computerized weapons utilizing 3D-printed auto sears, generally often called “Glock switches.” These converters allow semi-automatic pistols to fireplace at charges exceeding these of ordinary army rifles, elevating important public security issues.

In an interview with 3D Printing Business, Dr. Yannick Veilleux-Lepage, an Assistant Professor on the Royal Army School of Canada, supplied insights into how far-right extremists exploit 3D printing applied sciences to entry firearms. He famous that whereas the 3D-printed firearm group is numerous, its proximity to extremist ideologies poses dangers of radicalization and misuse. Nations like Singapore and Canada have enacted stricter laws on digital gun recordsdata and 3D-printed parts to curb their proliferation. In distinction, the USA faces authorized challenges resulting from First Modification protections for pc code, complicating federal efforts to manage 3D-printed firearms successfully.

In different information, Stratasys continued its patent infringement lawsuits in opposition to Bambu Lab, alleging that the latter infringed on ten of its patents associated to desktop FDM 3D printers. Whereas Stratasys dropped fees in opposition to two further defendants—Beijing Tiertime Know-how Co., Ltd. and Beijing Yinhua Laser Fast Prototyping and Mould Know-how Co. Ltd.—the core allegations in opposition to Bambu Lab stay. This authorized battle highlights the rising tensions between established OEMs and newer entrants providing aggressive 3D printing options, probably impacting mental property enforcement and innovation throughout the desktop 3D printing market.

Business Investments and Monetary Actions

WOL3D India Restricted (NSE: WOL3D) efficiently accomplished its oversubscribed Preliminary Public Providing (IPO) on the Nationwide Inventory Alternate’s Emerge platform in late September, with the momentum carrying into October. The IPO raised roughly ₹25.56 crore ($3.05M) by way of a contemporary problem of 1.45 million shares and an offer-for-sale of 252K shares, receiving bids 374 occasions the out there shares. Non-institutional traders led the demand, subscribing 749 occasions, signaling robust market confidence in India’s burgeoning 3D printing sector.

Rahul Chandalia, CEO of WOL3D, expressed gratitude for the overwhelming assist: “I’m extra dedicated than ever to driving innovation and delivering distinctive options that empower our purchasers and communities.” The proceeds from the IPO will probably be allotted in the direction of working capital and debt compensation, enabling WOL3D to broaden its operations and strengthen its presence in India’s quickly rising 3D printing market. With a reported 69% improve in revenues and a 109% development in revenue after tax (PAT) for the fiscal yr ending March 2024, WOL3D’s profitable IPO underscores the investor confidence in its numerous product portfolio, together with 3D printers, pens, and filaments, catering to sectors similar to manufacturing, engineering, and medical functions.

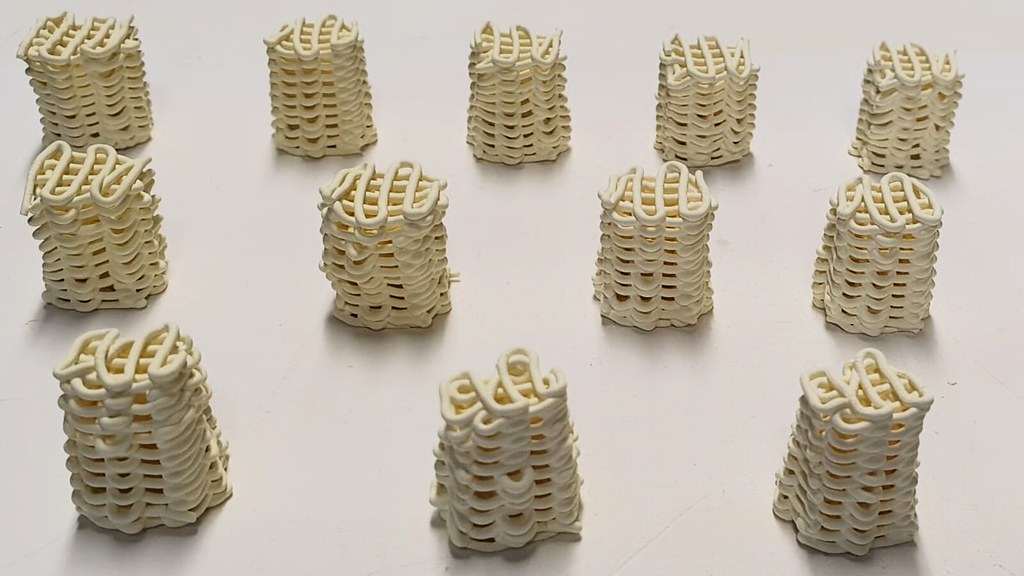

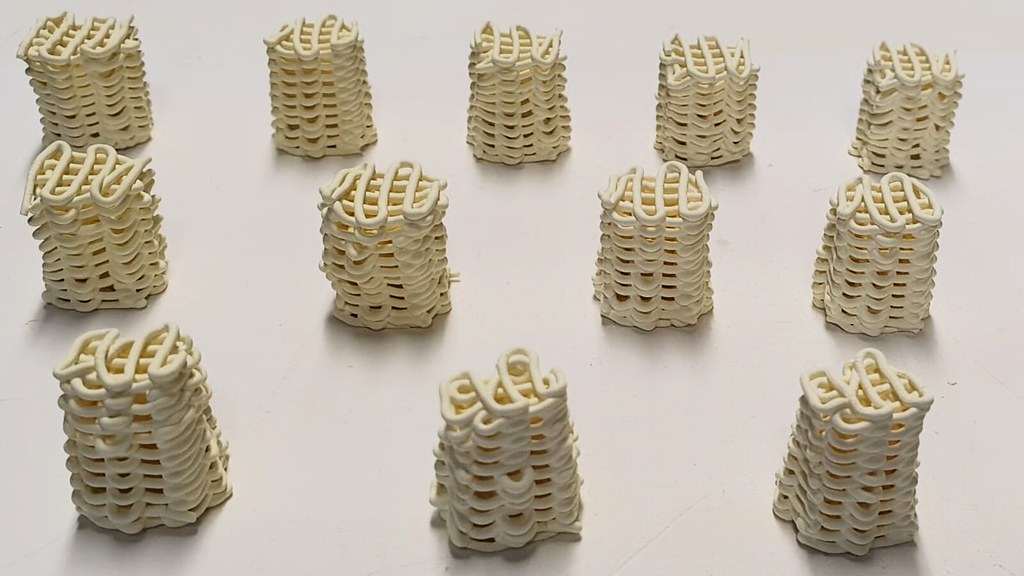

On the worldwide entrance, Nano Dimension (Nasdaq: NNDM) moved nearer to finishing its high-profile acquisition of Desktop Steel (NYSE: DM), securing over 96% shareholder approval. Valued at $183 million, the deal nonetheless awaited regulatory clearance as of late October however indicated a wave of consolidation in additive manufacturing. Nano Dimension had additionally introduced plans to amass Markforged for $115 million, aiming to merge a number of 3D printing applied sciences—from electronics to metals—right into a single, bigger company group. Some Desktop Steel traders expressed issues, given the corporate’s inventory had traded as excessive as $20 however had since fallen considerably. Nonetheless, CEO Ric Fulop described the merger as the perfect path to stabilize funds and advance Desktop Steel’s expertise pipeline, which incorporates single-pass jetting and different steel 3D printing choices.

Prepared to find who received the 2024 3D Printing Business Awards?

What is going to the way forward for 3D printing seem like?

Which latest traits are driving the 3D printing business, as highlighted by consultants?

Subscribe to the 3D Printing Business e-newsletter to remain up to date with the most recent information and insights.

Keep linked with the most recent in 3D printing by following us on Twitter and Fb, and don’t overlook to subscribe to the 3D Printing Business YouTube channel for extra unique content material.

Featured Picture exhibits Desktop Steel’s binder jet 3D printing expertise. Picture through Desktop Steel.