August 2019 Hacker of the Month, Chuck Taggart, makes use of 3D printing to invent merchandise and to create superb elements for his Harley Davidson bike.

Our August 2019 Hacker of the Month, Chuck Taggart, resides in Southlake, Texas. Chuck started his skilled profession as a civil engineer, planning, designing and overseeing development and upkeep of constructing constructions and infrastructure, however moved into insurance coverage about 15 years in the past. He at the moment owns a big medical health insurance company, Well being Reform Staff, based mostly in Grapevine, Texas.

Chuck started his journey into 3D printing after seeing a information phase on 3D printers about 5 years in the past. Quickly after, he determined to make the leap and buy his first 3D printer, a Zortrax M200. He additionally determined to get his kids concerned in 3D printing by having them design tasks on their iPads, which he then printed out for them so they might improve their creativity past digital designs.

The filter cleaner Chuck designed and is at the moment making use of for a patent.

Quickly after getting began, Chuck realized his designs had been a bit larger than the Zortrax may deal with, so he determined to upsize to a Modix 120X for actually big 3D printing capabilities.

Beginning with the Zortrax, Chuck primarily printed with ABS and used alcohol wiping and sanding to get a smoother end if he wanted it. However as soon as he moved as much as the Modix, he was in a position to actually begin printing with PETG and carbon-fiber infused NylonX. Chuck has used Autodesk123D Design for fairly a while, as he likes the comfort of taking his designs on the highway and dealing on them on flights and in his (restricted) spare time.

“I additionally created a neat contraption that may begin my Inexperienced Egg charcoal smoker remotely from wherever on the earth, in order that if I’m on my means residence and need to begin my Inexperienced Egg, I can do it from my iPhone.” You’ll be able to see a brief video rationalization of the starter field right here: https://youtu.be/60zBdc9jnks

Chuck’s distant Inexperienced Egg starter field.

However what’s the motivation behind Chuck’s 3D printing? “I simply have a head stuffed with concepts and I wish to tinker. If I want one thing to make my life simpler, then I take into consideration if I can 3D print it if it doesn’t exist. Or if I want an element that I may simply make or that not exists it’s cool to simply make one.”

The principle focus of Chuck’s designs heart on new creations and recreating elements that not exist. “For instance, I created and have filed for a patent on a system that cleans pool cartridge filters in a few minutes versus the usual means of hand spraying them.”

“ Additionally, final 12 months the daddy of a good friend of mine that’s into ’57 Ford Thunderbirds got here to me a couple of half for a supercharger (a cam ramp) that he says you possibly can’t get anymore. The unique inventory half was made out of a kind of plastic and was not very massive, but it surely was fairly complicated. It took a little bit of time, however I used to be in a position to make this half for him, after which needed to make a bunch extra for his associates. Now they’ve all of the elements they want.”

The Cam Ramp for the ’57 Ford Thunderbird Chuck designed and 3D printed.

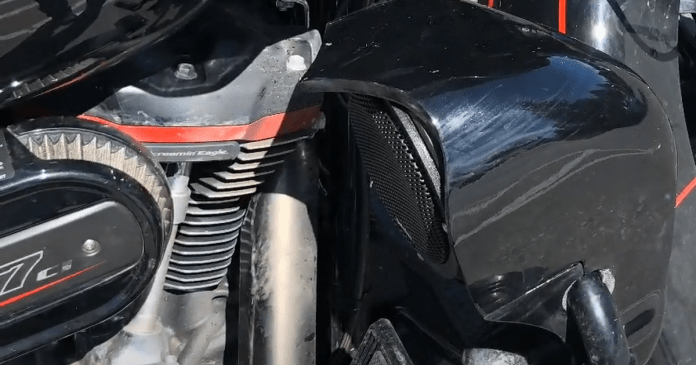

However essentially the most glamorous of all of Chuck’s tasks are made out of scratch – decrease fairings for his 2018 CVO Highway Glide Harley Davidson that merely didn’t exist earlier than he got here up with the concept to create them. “These really assist shield me whereas driving throughout the nation on a bike by preserving rain and rocks off my toes and decrease legs.”

Using the Modix 120X, Chuck was in a position to full the fairings in a single shot utilizing NylonX with out having to compromise the integrity of the print by combining smaller elements with glue or screws. (Excluding the clamp meeting to connect it to the body in fact.) The design additionally incorporates Rockford Fosgate audio system, they usually have an incredible end that makes them appear to be they got here with the bike. The undertaking took over 4 months to finish, from idea to printing, to complete.

However what’s Chuck trying ahead to with the way forward for 3D printing? “I’m certain the commonest factor individuals would reply with is pace, however there are some things I might love. First off could be a big lower in price for actual steel printing. I’ve been following this very carefully so when the associated fee will get down sufficient, I’m prepared for a steel printer. Second, could be customized coloring in real-time. For instance, similar to a coloration printer runs off of perhaps 6 coloration ink cartridges, it will be nice to see a 3D printer do that too.”

Chuck has additionally achieved a motorcycle construct from scratch – the Daryl Dixon bike from The Strolling Useless, which you’ll see movies of on his YouTube channel right here: https://www.youtube.com/person/CLTaggart/movies

Chuck’s subsequent undertaking is taking massive to the following stage; “I’m seeking to 3D print a convertible high for my Jeep Brute out of (in all probability) NylonX. I’ve it deliberate out and I’m within the design stage proper now.” We can’t wait to see the completed undertaking! If it seems to be something like his Harley Davidson fairings, Chuck could should stop the insurance coverage enterprise and begin going into customized fabrication. We are going to make sure to share extra photos of Chuck’s progress with all his upcoming tasks as quickly as there are updates!

Are you a 3D printing Hacker or know somebody that’s? We might like to share their story with the 3D printing neighborhood! Please e mail chris.morgan@matterhackers.com with data, and also you or your good friend could possibly be our featured Hacker of the Month.