AMAZEMET, a Warsaw-based firm, unveiled its revolutionary Powder2Powder (P2P) atomization system at Formnext 2024. This new system presents a flexible answer for recycling metallic powders and producing customized pre-alloy powders instantly from present powder feedstock, marking a major development in sustainable metallic powder manufacturing for the 3D printing trade.

The Powder2Powder system integrates plasma processing with ultrasonic atomization, reworking irregular or outsized particles into extremely spherical, satellite-free powders optimized for varied 3D printing strategies similar to Laser Powder Mattress Fusion (LPBF), Directed Vitality Deposition (DED), and Electron Beam Melting (EBM). In contrast to typical plasma spheroidization strategies, the P2P expertise permits powder dimension to stay impartial of the preliminary feedstock. This functionality makes it the one expertise presently able to instantly atomizing pulverized titanium (Ti) feedstock, setting a brand new benchmark in powder processing, in accordance with the corporate.

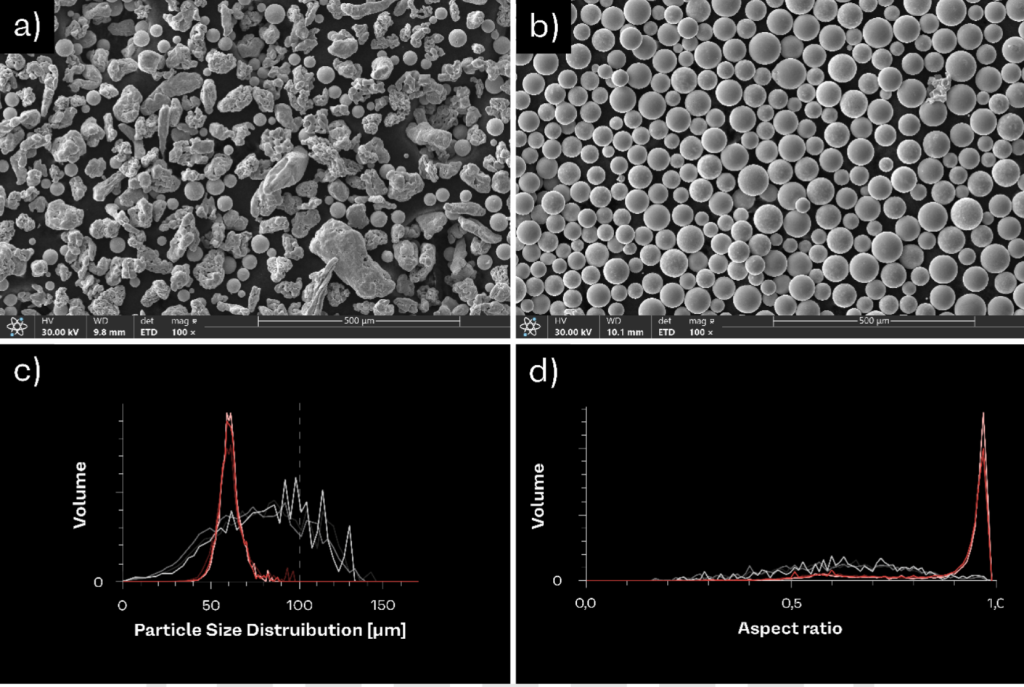

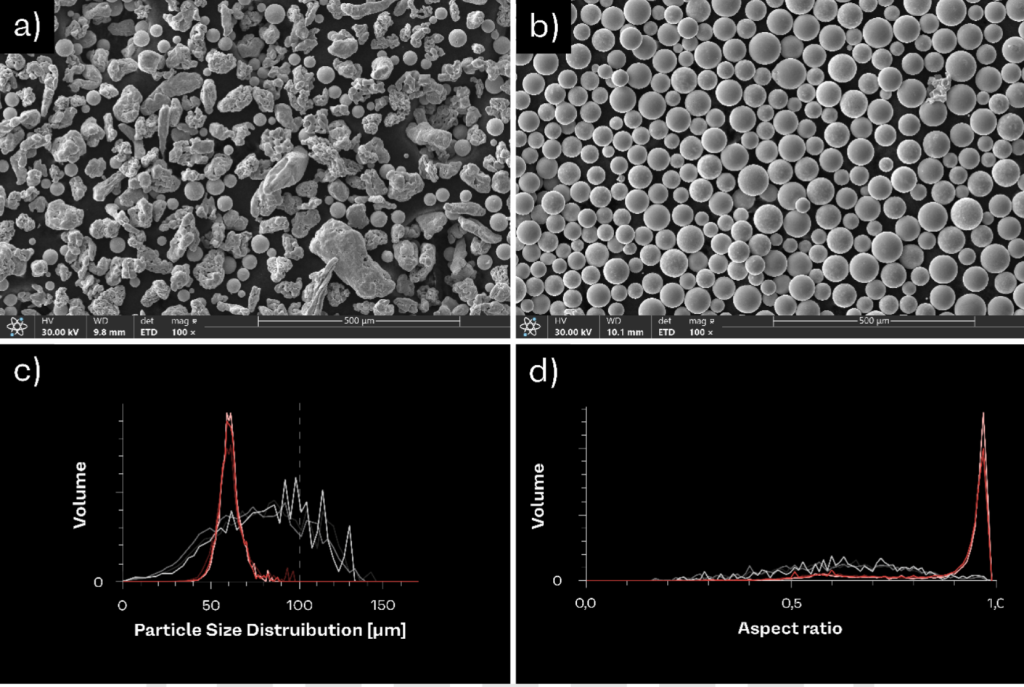

Intensive trials with over 200 μm outsized and irregular Ti alloy powders demonstrated the system’s distinctive efficiency. Working at a frequency of 40 kHz, the P2P system constantly achieved a powder morphology with a facet ratio (D50) exceeding 0.95 and a exact particle dimension distribution (PSD), producing powders with D90 beneath 80 μm and yielding particles below 63 μm at or above 80%. Roughly 97% of the ensuing powder meets the stringent necessities for additive manufacturing processes.

Past recycling, the P2P system excels in processing blends of elemental powders to create pre-alloyed supplies with exact chemical compositions. This characteristic is invaluable for each analysis and industrial functions, permitting for the fast improvement of latest alloys with out the necessity for intensive preprocessing, electrode casting, or wire drawing. Assessments with Ti and 10% wt. Mo elemental powders confirmed the formation of homogeneous alloy powders, demonstrating the system’s versatility and effectivity.

Łukasz Żrodowski, inventor and CEO of AMAZEMET, said, “The Powder2Powder system goes past recycling. It offers producers the power to customise powder compositions, enhance powder sphericity, and optimize particle dimension distribution, fixing essential points within the additive manufacturing trade. We showcased the way it enhances the effectivity and sustainability of powder-based manufacturing at Formnext 2024.”

Trade Advances in 3D Printing Supplies

On the similar occasion, PowderMonkeys, a model of Launhardt GmbH specializing in polymer powders for powder mattress fusion (PBF) processes, launched two superior supplies: Monkey SiPA12 and Monkey RePA12 50-8 GB. Established in 2021, PowderMonkeys provides supplies suitable with selective laser sintering (SLS) and high-speed sintering (HSS) platforms. Monkey SiPA12 is engineered for Sintratec machines, providing excessive mechanical energy and diminished waste, whereas Monkey RePA12 50-8 GB incorporates glass beads to reinforce tensile energy and thermal stability, offering a shiny end perfect for functions requiring each mechanical resilience and aesthetic high quality.

Stratasys, a number one 3D printer producer, additionally introduced SAF ReLife, an answer that repurposes waste PA12 powder into 3D printed elements. Supported by a Life Cycle Evaluation from Fraunhofer IPA, SAF ReLife reduces the carbon footprint of 3D printing by as much as 89%. This platform leverages Stratasys’ H350 powder mattress fusion 3D printer to supply purposeful elements from reclaimed powder, enhancing materials effectivity and supporting the round economic system by changing waste into high-quality merchandise.

Your voice issues within the 2024 3D Printing Trade Awards. Vote Now!

What is going to the way forward for 3D printing appear like?

Which current tendencies are driving the 3D printing trade, as highlighted by specialists?

Subscribe to the 3D Printing Trade publication to remain up to date with the newest information and insights.

Keep linked with the newest in 3D printing by following us on Twitter and Fb, and don’t overlook to subscribe to the 3D Printing Trade YouTube channel for extra unique content material.

Featured picture reveals atomization of TiMo alloy utilizing Powder2Powder expertise. Picture by way of AMAZEMET.