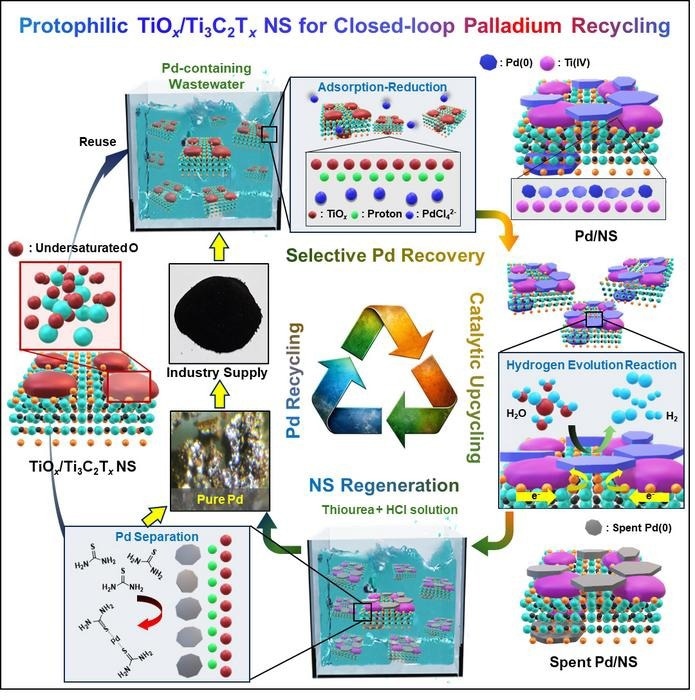

A analysis crew at KIST has developed an environmentally pleasant palladium restoration know-how utilizing titanium-based maxene nanosheets (TiOx/Ti3C2Tx).

Palladium (Pd) is extensively utilized in varied industries and on a regular basis merchandise, together with smartphones, semiconductor manufacturing, and hydrogen gas cells. Palladium features as a superb catalyst, even in hint quantities. It might probably assist cut back pollution and improve vitality effectivity.

However, palladium manufacturing is concentrated in a restricted variety of nations, leading to an unstable provide, and a scarcity of environmentally pleasant and environment friendly restoration applied sciences means a lot is both discarded or depends on international know-how.

Printed in Superior Purposeful Supplies, the examine, led by Dr. Jae-Woo Choi and Dr. Jin Younger Kim, demonstrates a nanocluster platform that may speed up Palladium manufacturing.

This know-how makes use of a high-density configuration of “TiOx nanoclusters” with unsaturated oxygen on the nanomaterial floor. It permits for the restoration of 99.9 % high-purity palladium in half-hour, even in weakly acidic situations the place typical strategies battle.

It doesn’t want poisonous chemical substances or an influence supply, and the recovered palladium spontaneously reduces to its metallic kind, facilitating separation by way of easy filtration. This leads to a considerable discount in vitality use and carbon emissions in comparison with present robust acid processes.

Furthermore, this materials demonstrates distinctive adsorption efficiency at 1,983 mg/g and retains roughly 90 % effectivity after over 10 reuse cycles, validating its stability and reusability. The recovered palladium-nanosheet composite may be repurposed as a hydrogen evolution catalyst, making it applicable for an entire valuable metallic recycling system.

This know-how features at room temperature, eliminating the necessity for high-temperature processing or harsh acidic chemical substances. Consequently, it’s projected to chop carbon emissions by 80 % or extra in comparison with present strategies. It additionally affords price advantages on account of its lack of electrical energy consumption and excessive industrial worth, as it’s reusable.

A major benefit is its big selection of purposes. It’s relevant as a catalyst in industries like refining, petrochemicals, automotive, and hydrogen gas cells, and for recovering palladium from digital waste, together with smartphones and circuit boards.

KIST researchers plan to additional refine this know-how for real-time therapy of palladium-containing wastewater from industrial sources. Their aim is a round useful resource ecosystem, reusing recovered palladium as a catalyst and digital materials.

Future growth consists of restoration applied sciences for different valuable metals, akin to platinum, gold, and silver.

This analysis represents a technological turning level that may contribute to the self-sufficiency of Korea’s useful resource circulation system and cut back dependence on valuable metallic imports by enabling the straightforward restoration of valuable metals beforehand discarded in spent catalysts or digital waste. We plan to reinforce commercialization potential by creating a modular restoration system sooner or later.

Dr. Jae-Woo Choi, Korea Institute of Science and Expertise

“We confirmed that the recovered palladium may be utilized not merely as recycled materials, however as an electrochemical electrode catalyst materials for producing high-efficiency hydrogen. We verified the potential for it to be utilized not as a ‘discarded metallic,’ however as a round useful resource supporting clear vitality manufacturing,” particulars Dr. Jin Younger Kim of KIST, who collaborated on the analysis.

Journal Reference:

Jung, Y., et al. (2025). Protophilic TiOx/Ti3C2Tz Nanosheets for Hyper-Environment friendly Closed-Loop Pd Recycling. Superior Purposeful Supplies. DOI: 10.1002/adfm.202511809.