A maker working beneath the model “Printed Pulse” has developed SignalForm, a 3D printed transportable speaker system designed to be repairable and customizable. The challenge goals to create an alternative choice to closed industrial audio techniques through the use of additive manufacturing methods and normal digital parts.

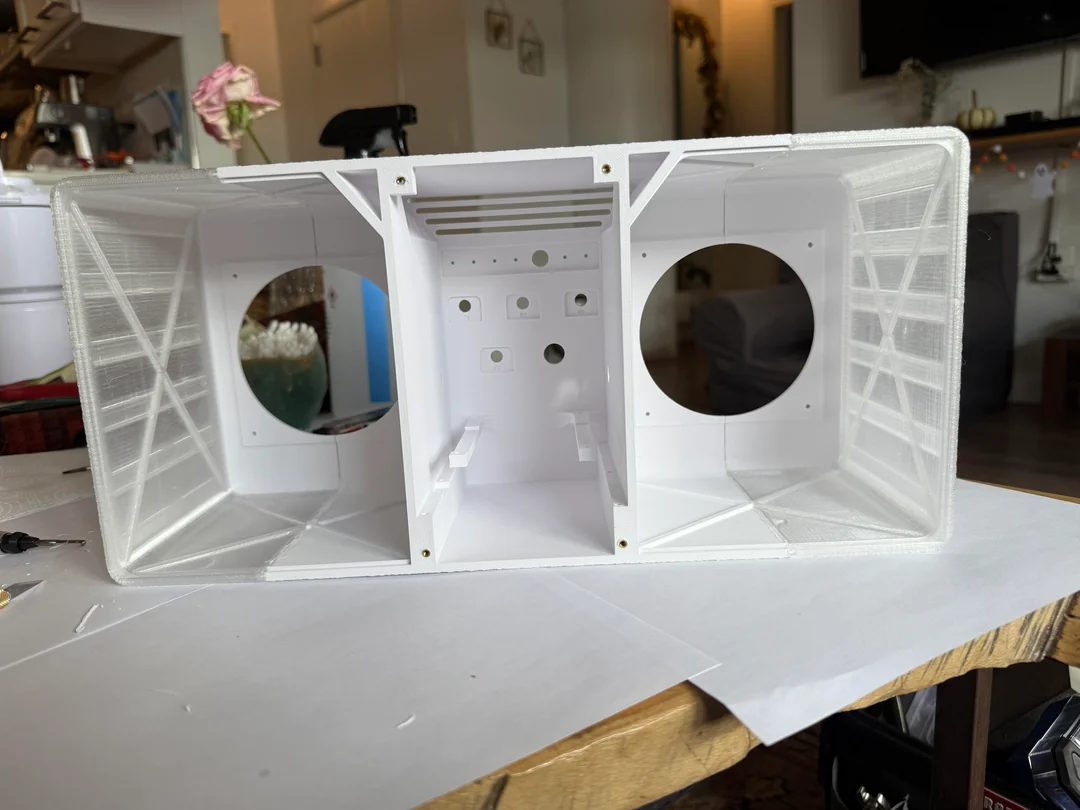

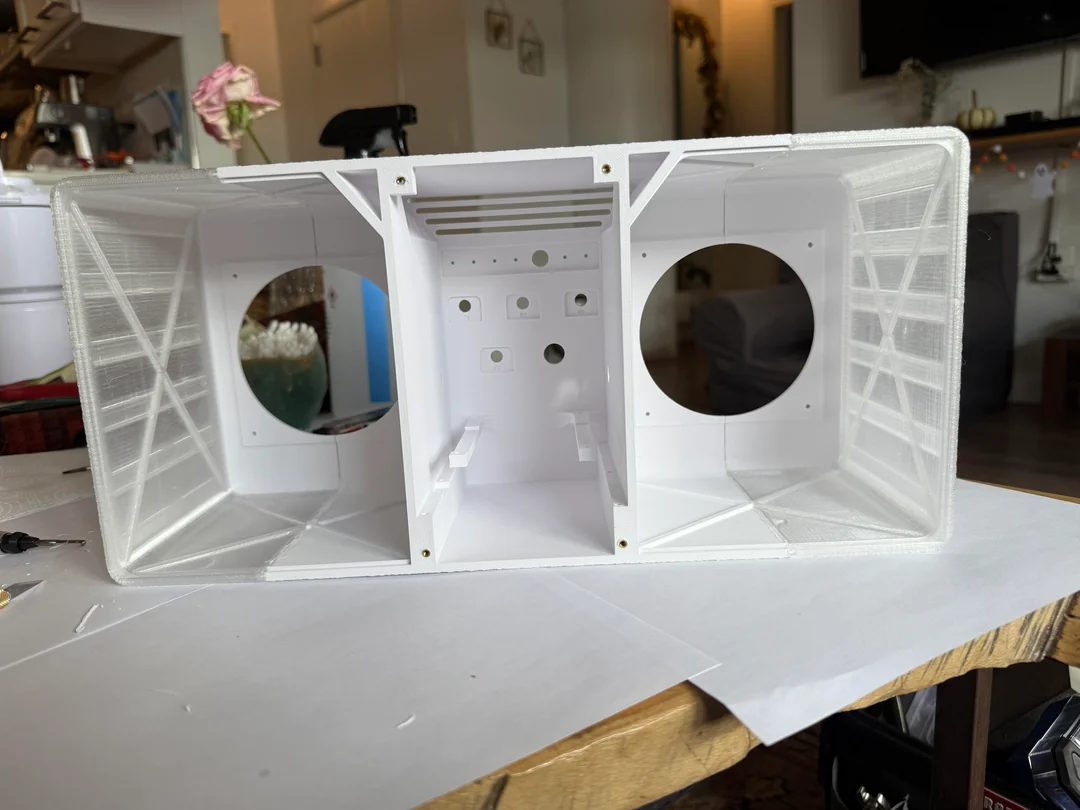

The speaker system encompasses a physique printed in Bambu PETG HF materials with translucent PETG panels and TPU isolation mounts for vibration management. It incorporates twin Dayton Audio DMA105-8 full-range drivers paired with ND105 passive radiators, powered by a Dayton Audio KABD-250 amplifier and a 5×18650 battery board offering 21V of energy. The enclosure consists of sealed chambers of roughly 2.8 liters every, with a central electronics bay that features cooling channels.

The audio system reportedly achieves a frequency response of 65 Hz to twenty kHz with output measuring round 95 dB at 2 meters. Controls embody bodily bass, mid, and treble changes, Bluetooth 5.0 with aptX HD assist, a 3.5mm auxiliary enter, and USB-C charging. The design makes use of no digital sign processing, relying as an alternative on acoustic design and driver pairing.

The challenge has been launched on MakerWorld as a community-driven construct, with plans to launch STL recordsdata, invoice of supplies, and meeting directions upon completion. The modular split-shell design permits printing on smaller beds and makes use of tongue-and-groove joints for meeting. The creator is in search of neighborhood suggestions on damping supplies, print settings, and methods for minimizing resonance in 3D printed audio enclosures.

Supply: reddit.com