Our prospects are proving every single day that elements produced with additive manufacturing can meet stringent manufacturing requirements throughout aerospace, medical, robotics and client items sectors.

The measurable outcomes they see together with quicker cycles, decrease prices, lowered danger and verified high quality are the true drivers, not the know-how itself. And these usually are not speculative advantages however are documented outcomes drawn from 1000’s of producing runs, design iterations and field-tested parts.

Right here we’ll share some anonymised case research exploring how our digital manufacturing platform interprets design freedom into production-grade outcomes.

Aerospace: From prototype to flight in weeks

One aerospace producer growing electrical plane wanted to design light-weight buildings that would stand up to aerodynamic masses whereas remaining serviceable in harsh out of doors circumstances. Conventional tooling would have meant six-figure funding and months of delay.

By shifting to additive manufacturing manufacturing for structural and non-critical parts, the engineering staff lowered design-to-flight time by greater than 40%. Every plane now integrates between 60 and 80 additively manufactured parts, together with housings, brackets, interface panels and sensor mounts all produced utilizing laser-sintered nylon and MJF PA12.

Over tons of of flight hours, none of those printed elements have proven degradation inside design masses. The corporate’s lead engineer put it plainly: 3D printing has turn out to be “as routine as machining, however quicker, lighter and simpler to validate.”

For aerospace initiatives the place certification and reliability rule each choice, that shift marks a real transformation: iterative engineering with out compromise.

Healthcare: Scaling innovation, defending property

order from a hospital.

In hospital environments, reliability is life-critical. A medical-equipment provider confronted recurring failures in cable administration methods that triggered downtime, issues of safety and value leakage. They labored with Shapeways to design a easy however strong 3D printed retention machine — sufficiently small to miss, however highly effective sufficient to forestall six-figure losses yearly.

Inside months, the provider had deployed over a thousand items, every digitally manufactured on demand from validated, biocompatible supplies. The consequence: a projected $1 million in tools property protected and near-zero alternative delays.

Elsewhere within the medical area, a design staff creating robotic-surgery coaching methods used additive manufacturing to reinvent the way in which surgeons be taught delicate procedures. Their problem was to simulate complicated, dexterous motions with out counting on costly cadaver or artificial fashions.

Utilizing selective laser sintering (SLS), the staff created tons of of modular elements, colour-coded and nested for environment friendly builds, and examined via fast iteration. The result was a completely modular coaching platform that could possibly be reconfigured for a number of talent ranges and shipped globally with out tooling. The designers estimate that Shapeways’ rapid-prototyping functionality lower their growth time by greater than half — and opened new prospects for data-driven medical schooling.

{Hardware} & Robotics: Manufacturing on the pace of innovation

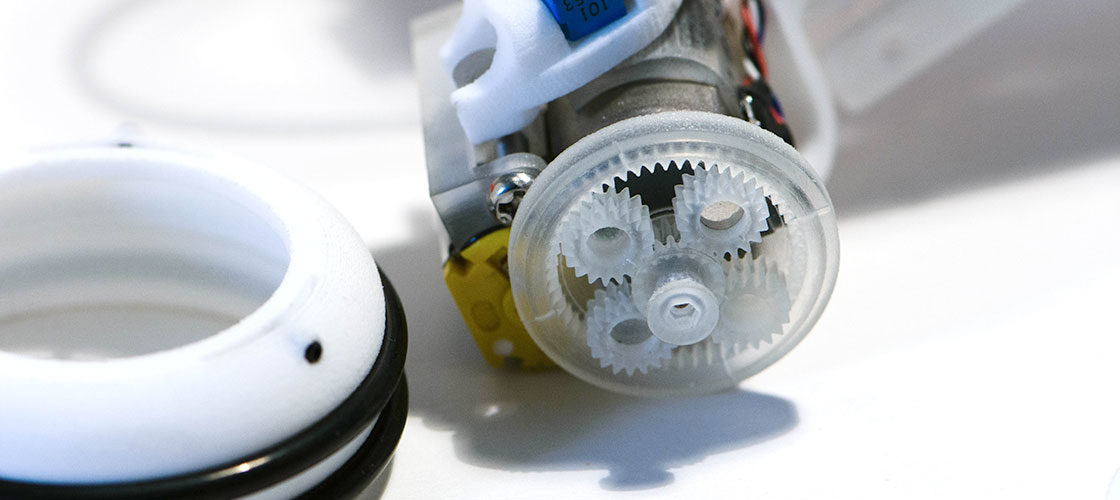

In high-tech {hardware} growth, time is the enemy of innovation. A robotics startup specialising in micro-manufacturing methods wanted to overtake a precision pick-and-place mechanism that wasn’t performing reliably. Early makes an attempt at in-house additive manufacturing manufacturing lacked precision and mechanical power; injection moulding was cost-prohibitive.

Shapeways produced the redesigned part in PA12, delivering superior rigidity and constant tolerances. The half dealt with twice the payload of the unique model, and the staff moved from prototype to manufacturing in days as an alternative of weeks.

That single enchancment cascaded via the corporate’s growth cycle, enabling quicker iteration and higher-quality finish merchandise. The identical companion moved on to supply practically all manufacturing parts via Shapeways’ certified manufacturing community, citing repeatability, dimensional accuracy and pace of supply as decisive elements.

Client & Design: Scaling bespoke manufacturing

Designers and client manufacturers are equally demanding in aesthetics, precision and consistency. One luxury-goods studio makes use of Shapeways’ steel and polymer printing to create algorithmically generated jewelry items which can be every distinctive however manufactured with sub-millimetre repeatability.

One other designer working an internet storefront scales world gross sales via Shapeways’ automated fulfilment: each order is printed, completed and shipped below their model, with no bodily stock or tooling price. In each instances, the flexibility to maneuver seamlessly from one-off creation to steady manufacturing is redefining the economics of bespoke manufacturing.

Their frequent denominator is just not inventive expression however manufacturing reliability utilising the identical high quality methods, inspection processes and traceability that energy Shapeways’ industrial prospects.

Throughout Industries: The metrics of contemporary manufacturing

Whereas all of those instances differ, the outcomes share a typical sample:

- 20–50% quicker growth cycles via fast iteration and digital validation

- Zero tooling funding and near-zero bodily stock, due to on-demand manufacturing

- Repeatable high quality and dimensional accuracy throughout batches and supplies

- Scalable workflows that reach from prototype to serial manufacturing with out course of change

These are the metrics that outline next-generation {hardware} manufacturing: not hypothetical future states, however measurable, repeatable efficiency achieved every single day by Shapeways’ prospects.

Turning proof into partnership

The shift from 3D printing as a novelty to additive manufacturing manufacturing as infrastructure has been ongoing for a few years. Producers ought to not ask whether or not it’s potential to print end-use elements; they need to search the quickest path to integrating them into manufacturing.

Behind each prototype or half is a partnership constructed on high quality assurance, supplies experience and manufacturing self-discipline. That’s what allows firms from startups to world OEMs to innovate quicker with out sacrificing reliability.