Velo3D, an AM know-how firm specializing in mission-critical metallic elements, has secured a $6 million contract to develop and qualify copper nickel alloy to be used in its Sapphire printer line. The qualification contains Velo3D’s large-format Laser Powder-Mattress Fusion (LPBF) Sapphire XC system and straight helps the U.S. Navy Maritime Industrial Base Program’s efforts to speed up ship restore timelines.

CuNi is broadly utilized in naval functions for its sturdy resistance to seawater corrosion. Nevertheless, conventional casting strategies create manufacturing challenges, usually requiring rework, larger prices, and longer lead occasions. Velo3D’s Speedy Manufacturing Answer (RPS) is designed to deal with these limitations, enabling quicker manufacturing than standard casting whereas strengthening shipbuilding schedules and provide chain resilience.

“Velo3D is proud to be the primary U.S.-based OEM with domestically developed Laser Powder-Mattress Fusion additive manufacturing options to develop CuNi for its programs,” stated Arun Jeldi, Velo3D CEO. “Via our Speedy Manufacturing Answer, we’re serving to present quicker half supply, enhanced reliability, and the surge capability wanted to satisfy evolving protection calls for.”

Advancing Provide Chain Independence and Protection Readiness

The qualification course of is being carried out at Velo3D’s Fremont, California, facility with the help of the U.S.-based, brazenly sourced metallic powder provider—serving to guarantee provide chain independence for the Navy. All Sapphire printers are assembled within the U.S., and the Sapphire XC, able to producing elements as much as 600 mm in diameter and 550 mm in top, might grow to be the primary printer of its dimension to qualify CuNi elements. This development expands addressable functions by enabling bigger elements, whereas delivering the advantages of LPBF, together with excessive constancy printing and Velo3D’s in-situ course of monitoring.

Velo3D added its programs adjust to DoD cybersecurity necessities and are able to securely integrating with navy networks, safeguarding the integrity and safety of crucial manufacturing processes.

Broader Additive Manufacturing Partnerships with U.S. Navy

In July, Synergy Additive Manufacturing, U.S.-based firm specializing in high-power laser programs, was awarded a Section I Small Enterprise Innovation Analysis (SBIR) contract by the Naval Air Techniques Command (NAVAIR). The undertaking goals to advance Extraordinarily Excessive-Pace Laser Cladding (EHLA) know-how to boost the lifespan and efficiency of titanium cylinder bores utilized in helicopter elements—a part of the U.S. Navy’s broader push to increase the lifetime of crucial aerospace elements, lower prices, and cut back upkeep downtime.

Individually, in 2021, 3D printer and filament provider MatterHackers was awarded a five-year Indefinite Supply, Indefinite Amount (IDIQ) contract valued as much as $5 million to supply absolutely deployable 3D printing programs to the U.S. Navy and Marine bases throughout the nation and abroad. The awarded contract for MatterHackers covers the supply of as much as 75 Tier 1 additive manufacturing programs by means of 2025. This package deal contains Ultimaker S5 industrial-grade 3D printers, premium filament supplies, devoted IT help, ongoing upkeep providers, and hands-on on-site coaching.

Registrations are actually open for Additive Manufacturing Benefit: Power on September seventeenth. Reserve your free ticket now! The decision for audio system can be open for Additive Manufacturing Benefit: Automotive & Mobility on October 1!

Wish to assist choose the winners of the 2025 3D Printing Business Awards? Register to hitch the Skilled Committee immediately.

Subscribe to the 3D Printing Business e-newsletter to maintain up with the newest 3D printing information.

It’s also possible to comply with us on LinkedIn, and subscribe to the 3D Printing Business Youtube channel to entry extra unique content material.

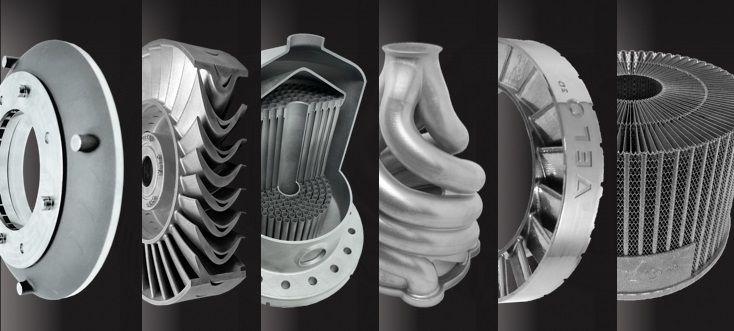

Featured picture present Vital alloys like Inconel, Copper, Aluminum and Titanium. Picture through Velo3D.