Diffusion fashions like OpenAI’s DALL-E have gotten more and more helpful in serving to brainstorm new designs. People can immediate these techniques to generate a picture, create a video, or refine a blueprint, and are available again with concepts they hadn’t thought-about earlier than.

However do you know that generative synthetic intelligence (GenAI) fashions are additionally making headway in creating working robots? Current diffusion-based approaches have generated buildings and the techniques that management them from scratch. With or with no consumer’s enter, these fashions could make new designs after which consider them in simulation earlier than they’re fabricated.

A brand new method from MIT’s Laptop Science and Synthetic Intelligence Laboratory (CSAIL) applies this generative know-how towards enhancing people’ robotic designs. Customers can draft a 3D mannequin of a robotic and specify which elements they’d wish to see a diffusion mannequin modify, offering its dimensions beforehand. GenAI then brainstorms the optimum form for these areas and exams its concepts in simulation. When the system finds the correct design, it can save you after which fabricate a working, real-world robotic with a 3D printer, with out requiring extra tweaks.

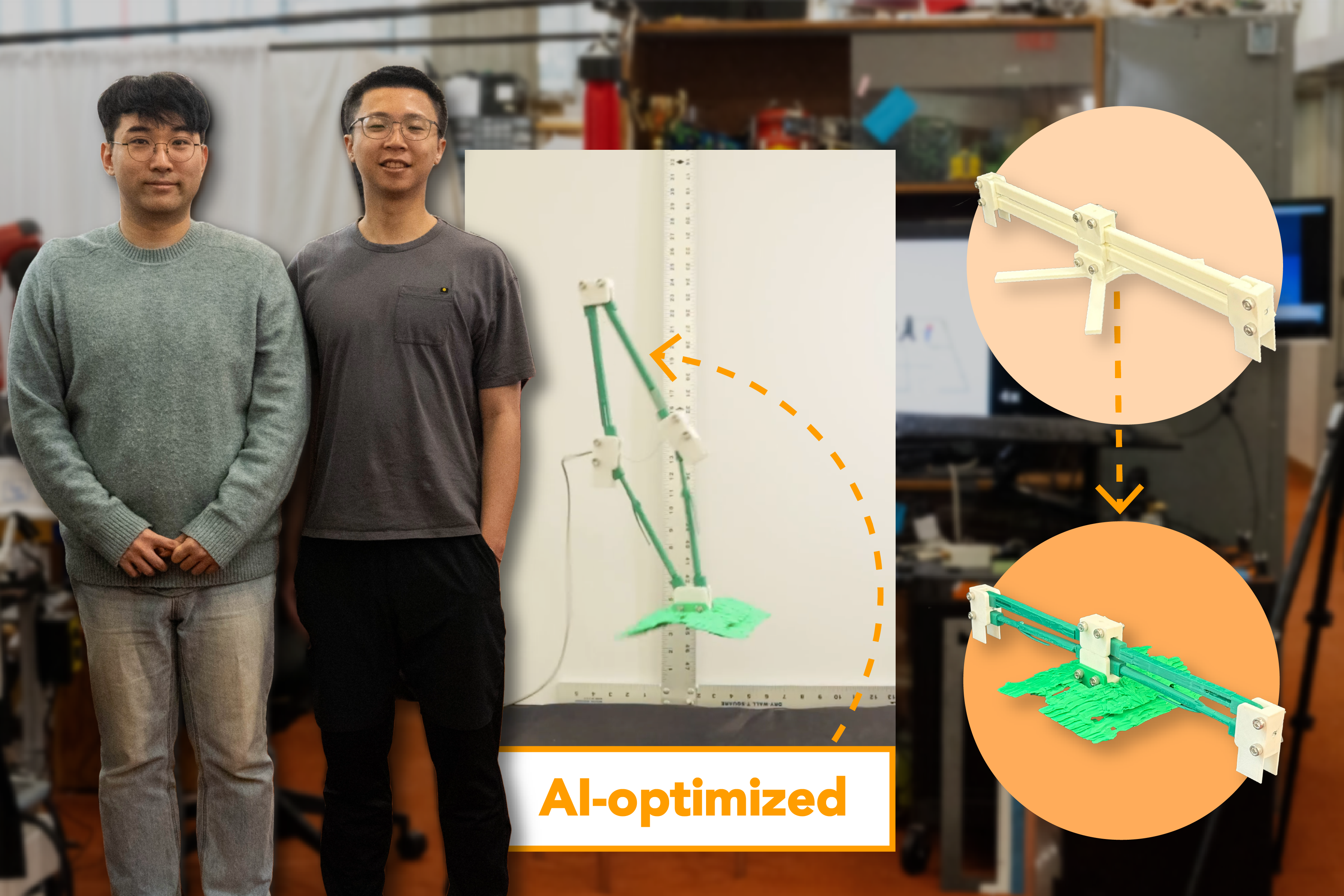

The researchers used this method to create a robotic that leaps up a median of roughly 2 ft, or 41 p.c increased than the same machine they created on their very own. The machines are almost similar in look: They’re each made from a kind of plastic known as polylactic acid, and whereas they initially seem flat, they spring up right into a diamond form when a motor pulls on the twine connected to them. So what precisely did AI do in another way?

A more in-depth look reveals that the AI-generated linkages are curved, and resemble thick drumsticks (the musical instrument drummers use), whereas the usual robotic’s connecting elements are straight and rectangular.

Higher and higher blobs

The researchers started to refine their leaping robotic by sampling 500 potential designs utilizing an preliminary embedding vector — a numerical illustration that captures high-level options to information the designs generated by the AI mannequin. From these, they chose the highest 12 choices based mostly on efficiency in simulation and used them to optimize the embedding vector.

This course of was repeated 5 instances, progressively guiding the AI mannequin to generate higher designs. The ensuing design resembled a blob, so the researchers prompted their system to scale the draft to suit their 3D mannequin. They then fabricated the form, discovering that it certainly improved the robotic’s leaping skills.

The benefit of utilizing diffusion fashions for this process, in accordance with co-lead writer and CSAIL postdoc Byungchul Kim, is that they’ll discover unconventional options to refine robots.

“We needed to make our machine bounce increased, so we figured we might simply make the hyperlinks connecting its elements as skinny as potential to make them mild,” says Kim. “Nevertheless, such a skinny construction can simply break if we simply use 3D printed materials. Our diffusion mannequin got here up with a greater thought by suggesting a singular form that allowed the robotic to retailer extra vitality earlier than it jumped, with out making the hyperlinks too skinny. This creativity helped us study in regards to the machine’s underlying physics.”

The workforce then tasked their system with drafting an optimized foot to make sure it landed safely. They repeated the optimization course of, finally selecting the best-performing design to connect to the underside of their machine. Kim and his colleagues discovered that their AI-designed machine fell far much less usually than its baseline, to the tune of an 84 p.c enchancment.

The diffusion mannequin’s capacity to improve a robotic’s leaping and touchdown abilities suggests it may very well be helpful in enhancing how different machines are designed. For instance, an organization engaged on manufacturing or family robots might use the same method to enhance their prototypes, saving engineers time usually reserved for iterating on these modifications.

The stability behind the bounce

To create a robotic that would bounce excessive and land stably, the researchers acknowledged that they wanted to strike a stability between each objectives. They represented each leaping peak and touchdown success price as numerical knowledge, after which skilled their system to discover a candy spot between each embedding vectors that would assist construct an optimum 3D construction.

The researchers notice that whereas this AI-assisted robotic outperformed its human-designed counterpart, it might quickly attain even larger new heights. This iteration concerned utilizing supplies that had been appropriate with a 3D printer, however future variations would bounce even increased with lighter supplies.

Co-lead writer and MIT CSAIL PhD scholar Tsun-Hsuan “Johnson” Wang says the venture is a jumping-off level for brand new robotics designs that generative AI might assist with.

“We need to department out to extra versatile objectives,” says Wang. “Think about utilizing pure language to information a diffusion mannequin to draft a robotic that may choose up a mug, or function an electrical drill.”

Kim says {that a} diffusion mannequin might additionally assist to generate articulation and ideate on how elements join, doubtlessly enhancing how excessive the robotic would bounce. The workforce can also be exploring the potential for including extra motors to regulate which course the machine jumps and maybe enhance its touchdown stability.

The researchers’ work was supported, partly, by the Nationwide Science Basis’s Rising Frontiers in Analysis and Innovation program, the Singapore-MIT Alliance for Analysis and Expertise’s Mens, Manus and Machina program, and the Gwangju Institute of Science and Expertise (GIST)-CSAIL Collaboration. They introduced their work on the 2025 Worldwide Convention on Robotics and Automation.